The primary limitations of machining Teflon (PTFE) are its inherent softness, low thermal conductivity, and high coefficient of thermal expansion. This unique combination makes it prone to deforming under clamping pressure, warping from localized heat buildup, and failing to hold tight tolerances. Its low mechanical strength and tendency to form heavy burrs instead of clean chips further complicate the creation of precise components.

While PTFE's exceptional properties like chemical inertness and low friction make it highly valuable, these same characteristics are the direct source of its machining challenges. The key is not to fight the material, but to accommodate its nature with specialized techniques.

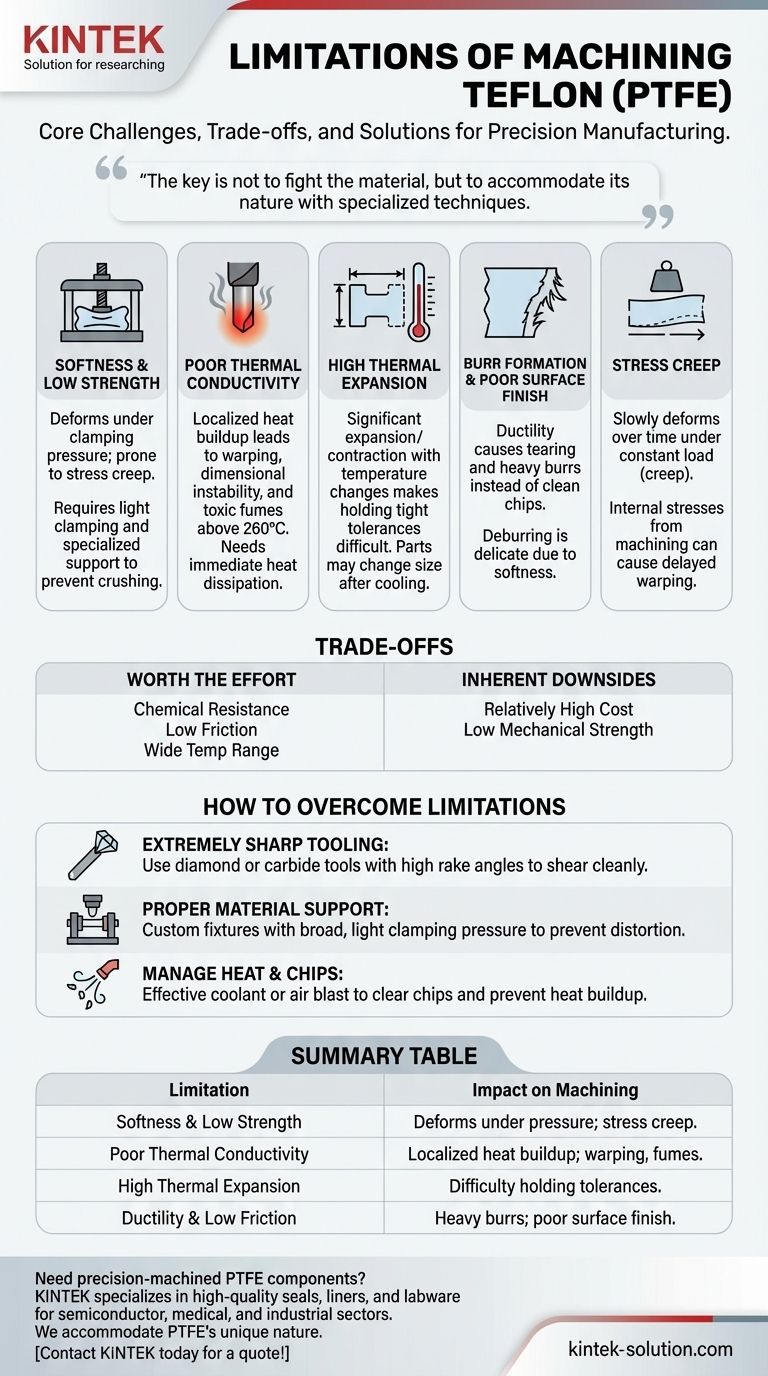

The Core Challenges of Machining PTFE

Understanding the specific ways PTFE behaves during machining is the first step toward overcoming its limitations. Each property presents a distinct challenge that requires a deliberate strategy to manage.

Deformation Under Pressure

PTFE is extremely soft and malleable. Standard clamping pressures used for metals or even other plastics can easily crush, distort, or mar the surface of a PTFE workpiece before a single cut is made.

This softness means the material tends to push away from the cutting tool rather than shear cleanly, leading to inaccuracies.

Poor Thermal Conductivity

Unlike metals that quickly dissipate heat, PTFE is an excellent insulator. The friction from a cutting tool generates heat that becomes concentrated in a very small area.

This localized heating can cause the material to soften, expand, or even break down, leading to warping and dimensional instability. If temperatures exceed 260°C (500°F), PTFE will begin to decompose and release toxic fumes, creating a significant safety hazard.

High Thermal Expansion

PTFE expands and contracts significantly with changes in temperature. Even the modest heat generated during a light machining pass can cause the material to grow.

This makes holding tight tolerances a primary challenge. A part that measures perfectly while warm from machining may be out of specification once it cools to room temperature.

Burr Formation and Poor Surface Finish

The material's ductility and low friction mean it often tears or smears instead of forming a clean chip. This behavior results in heavy, difficult-to-remove burrs along the edges of cuts.

Deburring PTFE is a delicate process, as the same softness that creates the burrs makes the part susceptible to damage during their removal.

Stress Creep and Low Strength

PTFE has low tensile strength and is subject to "creep," meaning it will slowly deform over time when under a constant load. This is a material limitation that must be considered in the part's final application.

During machining, internal stresses can be introduced, which may cause the part to warp or change shape hours or even days after the work is complete.

Understanding the Trade-offs

Despite these significant machining challenges, PTFE remains a critical material in many industries. Its limitations are tolerated because its advantages are often impossible to replicate with other polymers.

Why It's Worth the Effort

The primary drivers for choosing PTFE are its almost universal chemical resistance, an extremely low coefficient of friction (making it one of the slipperiest substances known), and a wide operational temperature range (from -200°C to 260°C).

The Inherent Downsides

Beyond machining difficulties, the main trade-offs are its relatively high cost compared to other polymers and its low mechanical strength. PTFE is not a structural material; it is a specialized material chosen for its surface properties, temperature range, and chemical inertness.

How to Overcome the Limitations

Successful PTFE machining relies on a specific set of best practices designed to mitigate the challenges mentioned above.

Use Extremely Sharp Tooling

This is the most critical factor. Tools must be exceptionally sharp, often with high rake and clearance angles, to shear the material cleanly rather than push it. Diamond or specific grades of carbide tooling are often recommended to maintain a sharp edge.

Provide Proper Material Support

Custom fixtures that support the entire workpiece are essential to prevent deformation. Clamping pressure must be distributed broadly and applied lightly to hold the part securely without distortion.

Manage Heat and Chips Effectively

Using a coolant is not always about cooling the part but about clearing chips immediately. A blast of compressed air or a non-aromatic, water-soluble flood coolant can prevent chips from building up, which would otherwise insulate the cutting zone and trap heat.

Making the Right Choice for Your Goal

Your machining strategy should be dictated by the most critical feature of your final part.

- If your primary focus is achieving tight tolerances: You must prioritize thermal management, using coolants and potentially letting the part normalize between roughing and finishing passes.

- If your primary focus is a clean, burr-free surface finish: The single most important factor is using extremely sharp, dedicated cutting tools with geometry designed for soft plastics.

- If your primary focus is preventing part deformation: Use custom-designed fixtures that provide maximum support with minimal, evenly distributed clamping pressure.

By acknowledging its limitations and adapting your technique, PTFE can be machined into highly precise and reliable components that leverage its unique and valuable properties.

Summary Table:

| Limitation | Impact on Machining |

|---|---|

| Softness & Low Strength | Deforms under clamping pressure; prone to stress creep. |

| Poor Thermal Conductivity | Localized heat buildup causes warping and toxic fumes. |

| High Thermal Expansion | Difficulty holding tight tolerances as part cools. |

| Ductility & Low Friction | Forms heavy burrs and poor surface finish instead of clean chips. |

Need precision-machined PTFE components that overcome these inherent challenges?

At KINTEK, we specialize in manufacturing high-quality PTFE components (seals, liners, labware, and more) for the semiconductor, medical, laboratory, and industrial sectors. Our expertise lies in accommodating PTFE's unique nature with specialized techniques, from custom fixtures to sharp tooling, ensuring your parts meet exact specifications without deformation or warping.

We offer custom fabrication from prototypes to high-volume orders, prioritizing precision production to deliver reliable components that leverage PTFE's exceptional chemical resistance and low friction.

Contact KINTEK today to discuss your project requirements and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability