The primary reasons to choose PTFE washers are their exceptional chemical resistance, broad temperature stability, and extremely low coefficient of friction. This unique combination of properties makes Polytetrafluoroethylene (PTFE) the material of choice for sealing and insulating applications in demanding environments where common materials would quickly fail.

PTFE is not a general-purpose material; it is a high-performance polymer engineered to solve specific challenges. You should choose it when your application involves aggressive chemicals, extreme temperatures, or the need for a non-stick, insulating surface that won't contaminate its surroundings.

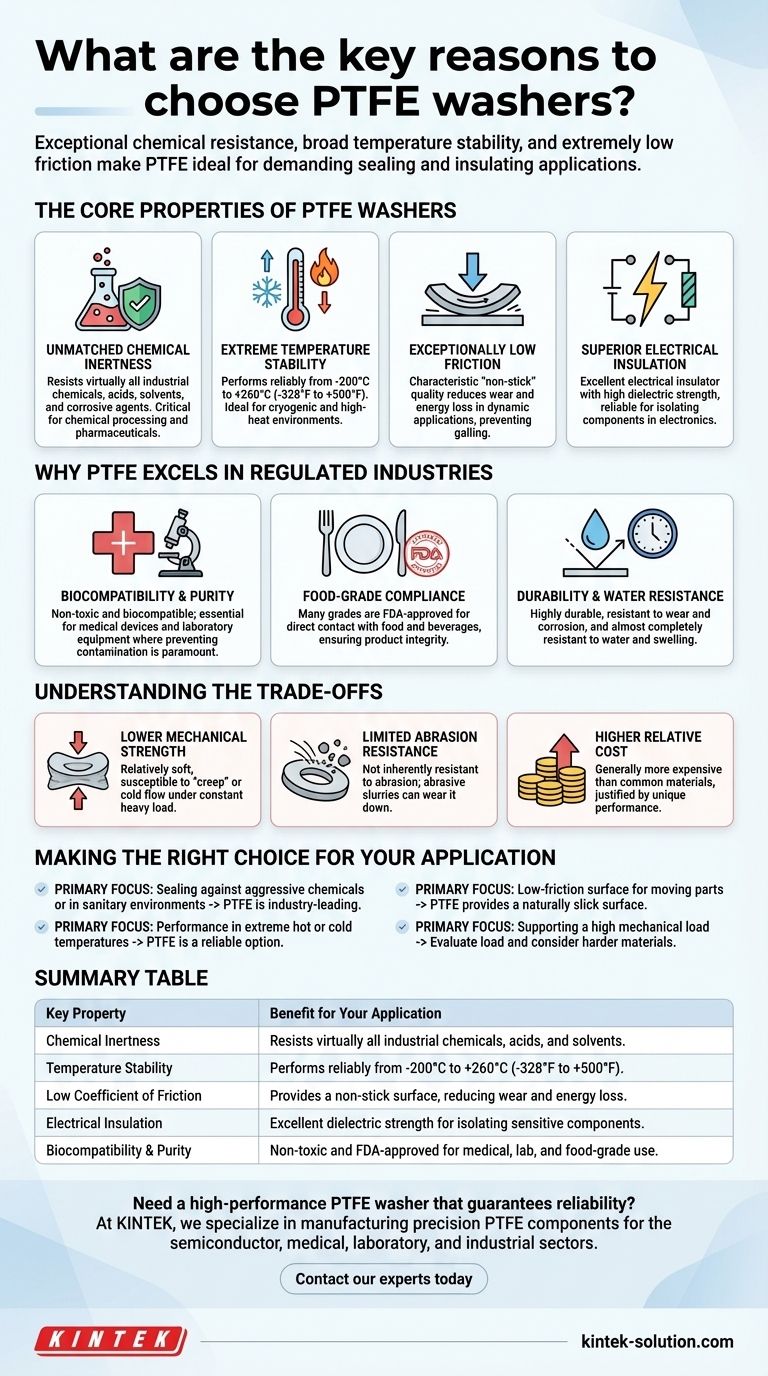

The Core Properties of PTFE Washers

To understand when to specify a PTFE washer, you must first understand its fundamental characteristics. These properties are not independent; they work together to create a uniquely versatile material.

Unmatched Chemical Inertness

PTFE is one of the most chemically resistant materials known. It is virtually inert to most industrial chemicals, acids, solvents, and corrosive agents.

This property is critical in industries like chemical processing and pharmaceuticals, where a washer must maintain its integrity without degrading or reacting with the substances it contacts.

Extreme Temperature Stability

PTFE washers perform reliably across an exceptionally wide temperature range, typically from -200°C to +260°C (-328°F to +500°F).

Unlike many plastics that become brittle at low temperatures or melt at high temperatures, PTFE retains its essential properties, making it ideal for everything from cryogenic equipment to high-heat engines and electronics.

Exceptionally Low Friction

PTFE has one of the lowest coefficients of friction of any solid material, giving it a characteristic "non-stick" quality.

This is highly beneficial for dynamic applications with moving parts, as it reduces wear and energy loss. It also facilitates easier installation and disassembly of components, preventing galling.

Superior Electrical Insulation

As an excellent electrical insulator, PTFE does not conduct electricity. It possesses a high dielectric strength, making it a reliable choice for isolating components in electronic and electrical assemblies.

This prevents short circuits and ensures the safety and reliability of sensitive electronic equipment.

Why PTFE Excels in Regulated Industries

The unique properties of PTFE make it a default choice for applications where purity, safety, and compliance are non-negotiable.

Biocompatibility and Purity

PTFE is non-toxic and biocompatible, meaning it does not cause adverse reactions when in contact with living tissue or sensitive fluids.

This makes it an essential material for medical devices, laboratory equipment, and pharmaceutical manufacturing, where preventing contamination is paramount.

Food-Grade Compliance

Many grades of PTFE are FDA-approved for direct contact with food and beverages.

Its non-contaminating and moisture-resistant nature ensures it won't leach chemicals or absorb substances, protecting the integrity of products in the food processing industry.

Durability and Water Resistance

PTFE is highly durable and resistant to wear and corrosion over its lifespan, which reduces the need for frequent replacements and maintenance.

Furthermore, it is almost completely resistant to water, preventing swelling or degradation in humid or submerged conditions.

Understanding the Trade-offs

While its benefits are significant, PTFE is not the solution for every problem. Objectively evaluating its limitations is crucial for proper material selection.

Lower Mechanical Strength

Compared to metals or other engineering plastics like PEEK, PTFE is a relatively soft material. It is susceptible to "creep" or cold flow, meaning it can slowly deform under a constant, heavy load.

For high-pressure structural applications, a different material or a filled-PTFE composite may be necessary.

Limited Abrasion Resistance

While PTFE's low friction reduces wear in sliding applications, it is not inherently resistant to abrasion from hard, sharp particles. Abrasive slurries can wear down a PTFE surface more quickly than a harder material.

Higher Relative Cost

As a high-performance polymer, PTFE is generally more expensive than washers made from common materials like rubber, nylon, or standard steel. Its cost is justified by its unique performance in environments where other materials are unsuitable.

Making the Right Choice for Your Application

Use these guidelines to determine if PTFE is the optimal choice for your specific goal.

- If your primary focus is sealing against aggressive chemicals or in sanitary environments: PTFE is an industry-leading choice due to its inertness and FDA-compliant grades.

- If your primary focus is performance in extreme hot or cold temperatures: PTFE's wide operating range makes it one of the most reliable options available.

- If your primary focus is a low-friction surface for moving parts: PTFE provides a naturally slick surface that minimizes wear and simplifies assembly.

- If your primary focus is supporting a high mechanical load: You should carefully evaluate the load and consider harder materials, as PTFE may deform over time.

Ultimately, choosing a PTFE washer is a decision to invest in reliability and longevity for applications where failure is not an option.

Summary Table:

| Key Property | Benefit for Your Application |

|---|---|

| Chemical Inertness | Resists virtually all industrial chemicals, acids, and solvents. |

| Temperature Stability | Performs reliably from -200°C to +260°C (-328°F to +500°F). |

| Low Coefficient of Friction | Provides a non-stick surface, reducing wear and energy loss. |

| Electrical Insulation | Excellent dielectric strength for isolating sensitive components. |

| Biocompatibility & Purity | Non-toxic and FDA-approved for medical, lab, and food-grade use. |

Need a high-performance PTFE washer that guarantees reliability?

At KINTEK, we specialize in manufacturing precision PTFE components—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. Whether you require a custom prototype or a high-volume order, our expertise ensures a solution that withstands aggressive chemicals, extreme temperatures, and demanding operational environments.

Contact our experts today to discuss your specific requirements and receive a tailored solution.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech