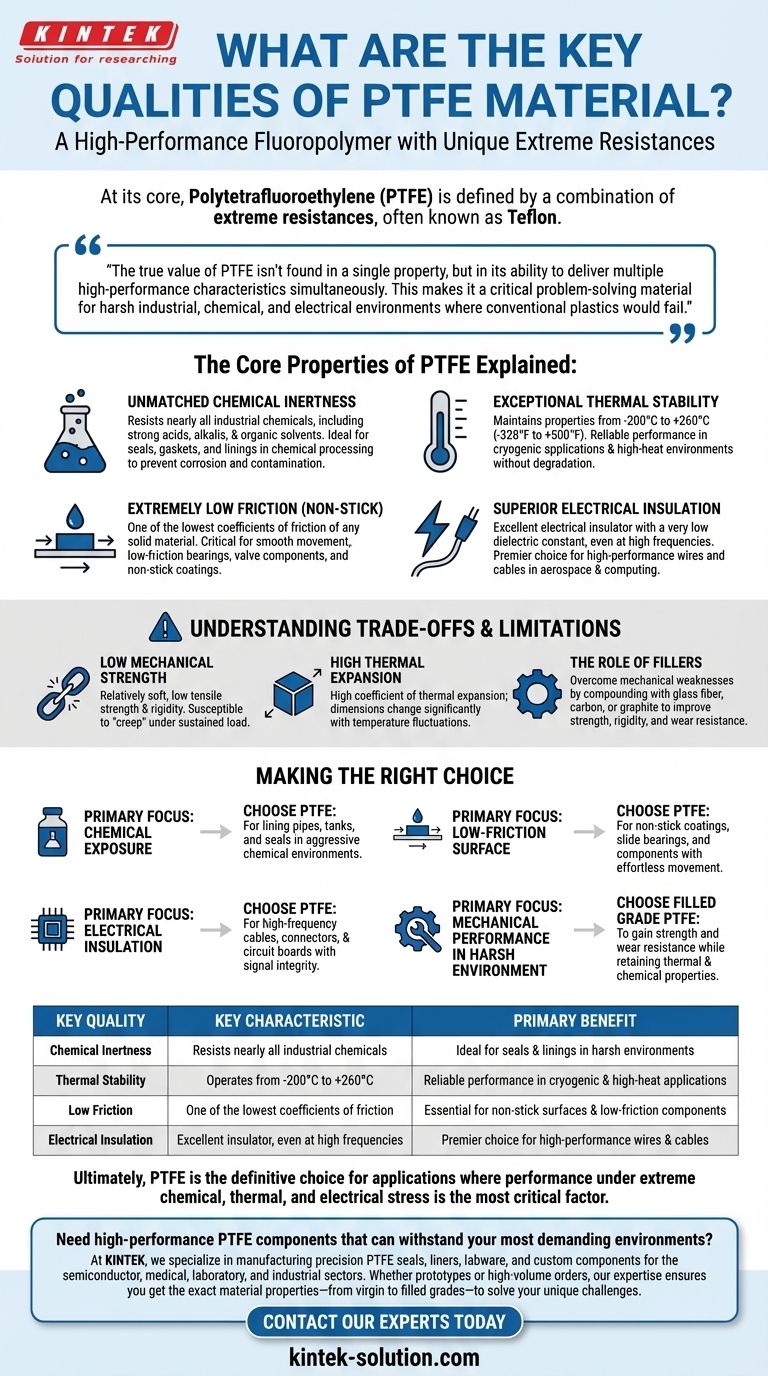

At its core, Polytetrafluoroethylene (PTFE) is a high-performance fluoropolymer defined by a unique combination of extreme resistances. Often known by the brand name Teflon, its key qualities include exceptional chemical inertness, a very wide operating temperature range, an extremely low coefficient of friction, and excellent electrical insulation.

The true value of PTFE isn't found in a single property, but in its ability to deliver multiple high-performance characteristics simultaneously. This makes it a critical problem-solving material for harsh industrial, chemical, and electrical environments where conventional plastics would fail.

The Core Properties of PTFE Explained

To understand when and why to use PTFE, it's essential to look at what each of its primary characteristics means in a practical application.

Unmatched Chemical Inertness

PTFE is famous for its resistance to nearly all industrial chemicals, including strong acids, alkalis, and organic solvents.

This extreme inertness makes it an ideal material for seals, gaskets, and linings in chemical processing equipment, preventing corrosion and contamination.

Exceptional Thermal Stability

PTFE maintains its properties across a vast temperature range, typically from -200°C to +260°C (-328°F to +500°F).

This allows it to perform reliably in both cryogenic applications and high-heat environments without degrading, a feat few other polymers can achieve.

Extremely Low Friction (Non-Stick)

PTFE has one of the lowest coefficients of friction of any known solid material, which gives it its characteristic non-stick, or "lubricious," surface.

This property is critical for applications requiring smooth movement with minimal resistance, such as low-friction bearings, valve components, and non-stick coatings.

Superior Electrical Insulation

PTFE is an excellent electrical insulator with a very low dielectric constant, even at high frequencies.

Its ability to resist electrical flow makes it a premier choice for insulating high-performance wires and cables, particularly in aerospace and computing applications.

Understanding the Trade-offs and Limitations

While its resistances are world-class, PTFE is not the right choice for every application. Its primary limitations are mechanical.

Low Mechanical Strength

Virgin PTFE is a relatively soft material with low tensile strength and rigidity compared to other engineering plastics.

It can be susceptible to "creep," or deformation under a sustained load, making it unsuitable for high-load structural components on its own.

High Thermal Expansion

PTFE has a high coefficient of thermal expansion, meaning its dimensions can change significantly with temperature fluctuations.

This must be accounted for in engineering designs that require tight tolerances to prevent parts from failing due to expansion or contraction.

The Role of Fillers

To overcome its mechanical weaknesses, PTFE is often compounded with fillers like glass fiber, carbon, or graphite.

These fillers dramatically improve strength, rigidity, and wear resistance, though they can sometimes slightly reduce the material's chemical resistance or increase its coefficient of friction.

Making the Right Choice for Your Application

Selecting PTFE requires matching its unique strengths to the primary challenge of your project.

- If your primary focus is chemical exposure: PTFE is an almost unbeatable choice for lining pipes, tanks, and creating seals in aggressive chemical environments.

- If your primary focus is a low-friction surface: PTFE is the ideal material for non-stick coatings, slide bearings, and components that need to move effortlessly.

- If your primary focus is electrical insulation: PTFE provides excellent performance for high-frequency cables, connectors, and circuit boards where signal integrity is paramount.

- If your primary focus is mechanical performance in a harsh environment: Choose a filled grade of PTFE to gain the necessary strength and wear resistance while retaining excellent thermal and chemical properties.

Ultimately, PTFE is the definitive choice for applications where performance under extreme chemical, thermal, and electrical stress is the most critical factor.

Summary Table:

| Key Quality | Key Characteristic | Primary Benefit |

|---|---|---|

| Chemical Inertness | Resists nearly all industrial chemicals | Ideal for seals & linings in harsh environments |

| Thermal Stability | Operates from -200°C to +260°C | Reliable performance in cryogenic & high-heat applications |

| Low Friction | One of the lowest coefficients of friction | Essential for non-stick surfaces & low-friction components |

| Electrical Insulation | Excellent insulator, even at high frequencies | Premier choice for high-performance wires & cables |

Need high-performance PTFE components that can withstand your most demanding environments?

At KINTEK, we specialize in manufacturing precision PTFE seals, liners, labware, and custom components for the semiconductor, medical, laboratory, and industrial sectors. Whether you require prototypes or high-volume orders, our expertise ensures you get the exact material properties—from virgin to filled grades—to solve your unique challenges.

Contact our experts today to discuss your application and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments