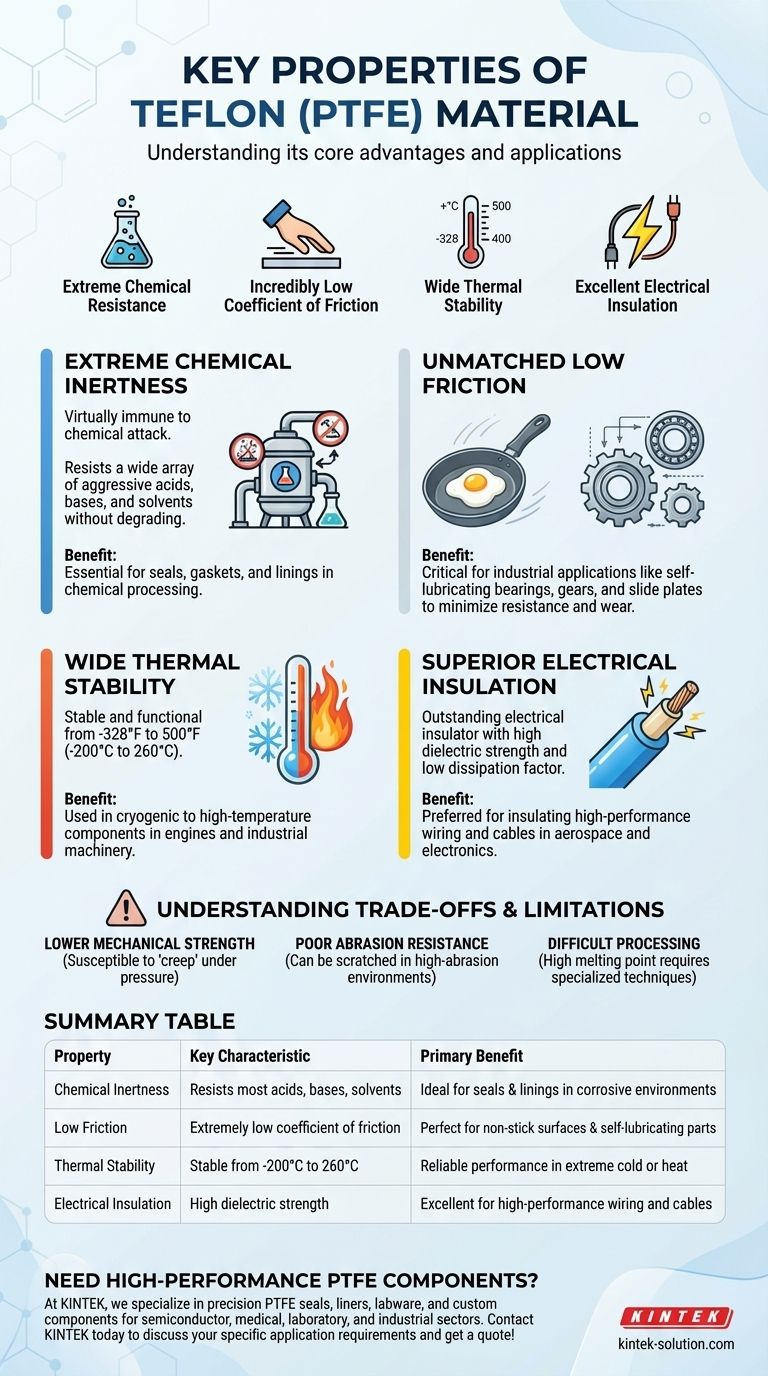

At its core, Teflon is defined by four exceptional properties. This material, formally known as Polytetrafluoroethylene (PTFE), is celebrated for its extreme chemical resistance, an incredibly low coefficient of friction that creates non-stick surfaces, stability across a vast range of temperatures, and excellent performance as an electrical insulator.

Teflon's unique combination of near-total chemical inertness and extreme slipperiness is not an accident; it is the direct result of the powerful and stable bonds between carbon and fluorine atoms, making it one of the most versatile and reliable synthetic polymers ever created.

The Foundation: Understanding PTFE

Polytetrafluoroethylene (PTFE) is a synthetic fluoropolymer, a high-molecular-weight compound consisting entirely of carbon and fluorine. The exceptional strength and stability of the carbon-fluorine bond are the source of almost all of Teflon's signature properties.

This molecular structure creates a material that is highly unreactive and durable, setting it apart from nearly all other plastics and polymers in demanding industrial, commercial, and consumer applications.

A Breakdown of Teflon's Core Properties

Each of Teflon's key characteristics makes it uniquely suited for specific, often challenging, environments where other materials would quickly fail.

Extreme Chemical Inertness

Teflon is virtually immune to chemical attack. It can withstand exposure to a wide array of aggressive acids, bases, and solvents without degrading.

This makes it an essential material for seals, gaskets, and linings in chemical processing, where it ensures the integrity of equipment handling corrosive substances. Only a few materials, like molten alkali metals, can affect it.

Unmatched Low Friction

Teflon possesses one of the lowest coefficients of friction of any known solid material. This gives it its famous "non-stick" or anti-adhesive quality.

This property is not only valuable for cookware but is critical for industrial applications like self-lubricating bearings, gears, and slide plates where minimizing resistance and wear is paramount.

Wide Thermal Stability

The material remains stable and functional across an exceptionally broad temperature range, typically from -328°F to 500°F (-200°C to 260°C).

This allows Teflon to be used in everything from cryogenic applications to high-temperature components in engines and industrial machinery without losing its structural integrity or key properties.

Superior Electrical Insulation

Teflon is an outstanding electrical insulator with a high dielectric strength and a low dissipation factor. It effectively blocks the flow of electricity, even at high frequencies.

These characteristics make it a preferred material for insulating high-performance wiring and cables, particularly in aerospace and computer applications where signal integrity is crucial.

Environmental Durability

Beyond its other resistances, Teflon is highly resistant to weathering and UV radiation. It does not become brittle or break down when exposed to sunlight and moisture over long periods. This ensures a long service life for outdoor components.

Understanding the Trade-offs and Limitations

While its properties are exceptional, Teflon is not the ideal choice for every scenario. Understanding its limitations is key to using it effectively.

Lower Mechanical Strength

Compared to other engineering plastics, PTFE is a relatively soft material. It has lower tensile strength and is susceptible to "creep," or cold flow, where the material deforms under sustained pressure.

Poor Abrasion Resistance

Because it is soft, Teflon can be scratched or worn away relatively easily in high-abrasion environments. While its low friction helps, direct contact with abrasive materials can degrade the surface.

Difficult Processing

Teflon has a very high melting point and extremely high melt viscosity, which makes it unsuitable for common processing methods like injection molding. It typically requires specialized techniques like compression molding and sintering.

Making the Right Choice for Your Application

Selecting a material requires matching its properties to the primary challenge you need to solve.

- If your primary focus is non-stick surfaces or low-friction movement: Teflon is the industry standard for coatings, linings, and self-lubricating bearings.

- If you are handling highly corrosive chemicals: Its near-total inertness makes it the definitive choice for seals, gaskets, and fluid handling components.

- If your application involves extreme temperature ranges: Its stability from cryogenic levels to high heat ensures reliable performance where other polymers would fail.

- If you require high-performance electrical insulation: Its superior dielectric properties are essential for high-frequency cables and critical electronic components.

Ultimately, Teflon's value lies in its ability to perform reliably in environments that would destroy lesser materials.

Summary Table:

| Property | Key Characteristic | Primary Benefit |

|---|---|---|

| Chemical Inertness | Resists almost all acids, bases, and solvents. | Ideal for seals and linings in corrosive environments. |

| Low Friction | Extremely low coefficient of friction. | Perfect for non-stick surfaces and self-lubricating parts. |

| Thermal Stability | Stable from -200°C to 260°C. | Reliable performance in extreme cold or heat. |

| Electrical Insulation | High dielectric strength. | Excellent for high-performance wiring and cables. |

Need high-performance PTFE components that leverage these exceptional properties?

At KINTEK, we specialize in manufacturing precision PTFE seals, liners, labware, and custom components for the semiconductor, medical, laboratory, and industrial sectors. Whether you need prototypes or high-volume orders, our expertise ensures your parts meet the highest standards of chemical resistance, thermal stability, and reliability.

Contact KINTEK today to discuss your specific application requirements and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application