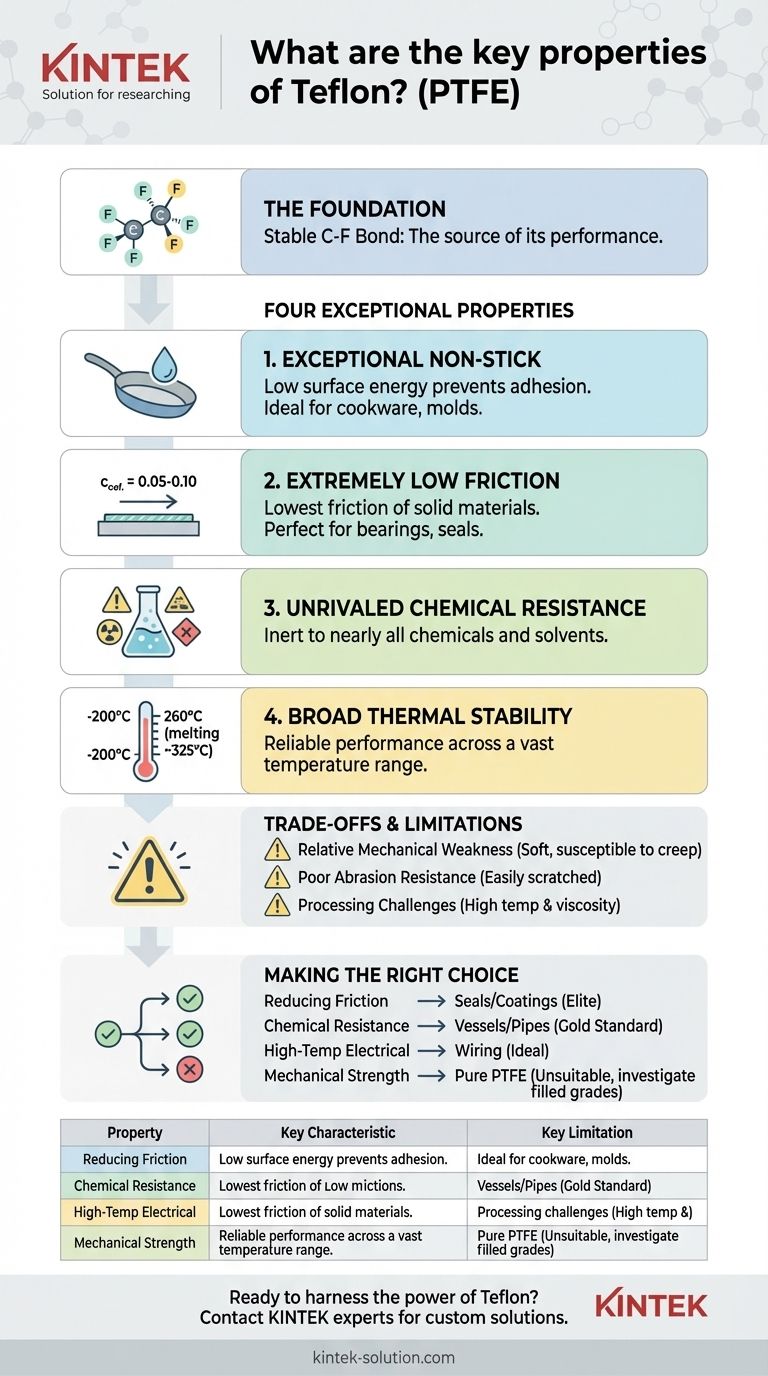

At its core, Teflon is defined by four exceptional properties. This material, known chemically as polytetrafluoroethylene (PTFE), is celebrated for its extreme non-stickiness, incredibly low friction, near-total chemical inertness, and reliable stability across a vast range of temperatures. Its unique molecular structure is the source of this high-performance profile.

The remarkable characteristics of Teflon are not independent features but are all consequences of its underlying chemistry. The strength and stability of the carbon-fluorine bond create one of the most non-reactive and low-friction materials ever engineered, making it indispensable in demanding applications.

The Foundation: Why PTFE is So Stable

Before examining its performance properties, it's critical to understand the source of Teflon's unique behavior: its molecular structure.

The Carbon-Fluorine Bond

PTFE is a fluoropolymer, consisting of a long chain of carbon atoms completely surrounded by fluorine atoms. The bond between carbon and fluorine is exceptionally strong and stable.

A Chemically Inert Shield

This sheath of fluorine atoms effectively protects the carbon backbone from attack. This structure creates an extremely non-reactive surface with very low surface energy, which is the fundamental reason for most of Teflon's famous properties.

Key Performance Properties Explained

The stable molecular structure of PTFE gives rise to several high-value mechanical, thermal, and chemical properties.

Exceptional Non-Stick Surface

The low surface energy from the fluorine atoms prevents almost any substance from adhering to it. This makes it an ideal material for non-stick cookware, mold release agents, and surfaces that must remain clean.

Extremely Low Friction

PTFE possesses one of the lowest coefficients of friction of any known solid material. Its friction coefficient against polished steel can be as low as 0.05 to 0.10, making it an excellent choice for bearings, seals, and other low-friction coatings.

Unrivaled Chemical Resistance

Due to its inert chemical structure, Teflon is non-reactive to nearly all chemicals, solvents, and corrosive agents. Only a few highly reactive substances, such as molten alkali metals, can affect it.

Broad Thermal Stability

Teflon performs reliably across an exceptionally wide temperature range, from as low as -200°C (-328°F) up to 260°C (500°F). It has a high melting point of around 325°C (617°F), allowing it to handle applications where other polymers would fail.

Excellent Electrical Insulation

PTFE is a superb electrical insulator with high dielectric strength and low electrical loss. This makes it a critical material for high-performance wiring, coaxial cables, and printed circuit boards, especially in high-frequency applications.

Understanding the Trade-offs and Limitations

While powerful, PTFE is not the solution for every problem. Its unique properties come with inherent limitations that are crucial to recognize.

Relative Mechanical Weakness

Compared to engineering plastics, pure PTFE is a soft material. It has relatively low tensile strength and is susceptible to "creep," or deformation under sustained pressure.

Poor Abrasion Resistance

The same softness that contributes to its low friction also makes it vulnerable to scratching and abrasion. This is why non-stick pan coatings can be easily damaged by metal utensils.

Processing Challenges

Teflon's high melting temperature and high melt viscosity make it very difficult to process with conventional methods like injection molding. It typically requires specialized techniques such as compression molding and sintering.

Making the Right Choice for Your Application

To leverage PTFE effectively, align its strengths with your primary goal.

- If your primary focus is reducing friction: PTFE is an elite choice for seals, bushings, and coatings where mechanical loads are not excessively high.

- If your primary focus is chemical resistance: It is the gold standard for lining vessels, pipes, and valves that handle highly corrosive or pure substances.

- If your primary focus is high-temperature electrical performance: Its stability and dielectric properties are ideal for insulating critical wiring and high-frequency components.

- If your primary focus is mechanical strength and wear resistance: Pure PTFE is likely unsuitable; you should investigate filled grades of PTFE that incorporate glass, carbon, or other agents to improve durability.

Understanding both the strengths and the limitations of Teflon's properties is the key to deploying it successfully in your project.

Summary Table:

| Property | Key Characteristic | Key Limitation |

|---|---|---|

| Non-Stick & Low Friction | Extremely low surface energy and friction coefficient (0.05-0.10). | Soft material with poor abrasion resistance. |

| Chemical Resistance | Inert to nearly all chemicals and solvents. | Can be affected by highly reactive substances like molten alkali metals. |

| Thermal Stability | Performs from -200°C to 260°C; melts at ~325°C. | Relatively low tensile strength and susceptible to creep. |

| Electrical Insulation | Excellent dielectric strength, ideal for high-frequency applications. | Difficult to process with conventional methods like injection molding. |

Ready to harness the power of Teflon for your project?

KINTEK specializes in the precision manufacturing of high-performance PTFE components—including custom seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. Whether you need prototypes or high-volume orders, our expertise ensures your application benefits from Teflon's unique properties while mitigating its limitations.

Contact our experts today to discuss your specific requirements and get a custom solution quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability