At its core, Polytetrafluoroethylene (PTFE) is prized for an exceptional combination of four key properties. It exhibits near-total chemical inertness, operates across a vast range of temperatures, possesses an extremely low coefficient of friction, and provides excellent electrical insulation. This unique profile makes it a highly versatile and reliable material for demanding industrial environments.

The true value of PTFE isn't any single property, but its ability to maintain high performance across multiple extreme conditions simultaneously. It solves problems where materials are exposed to corrosive chemicals, high temperatures, and high friction all at once, making it a default choice for mission-critical applications.

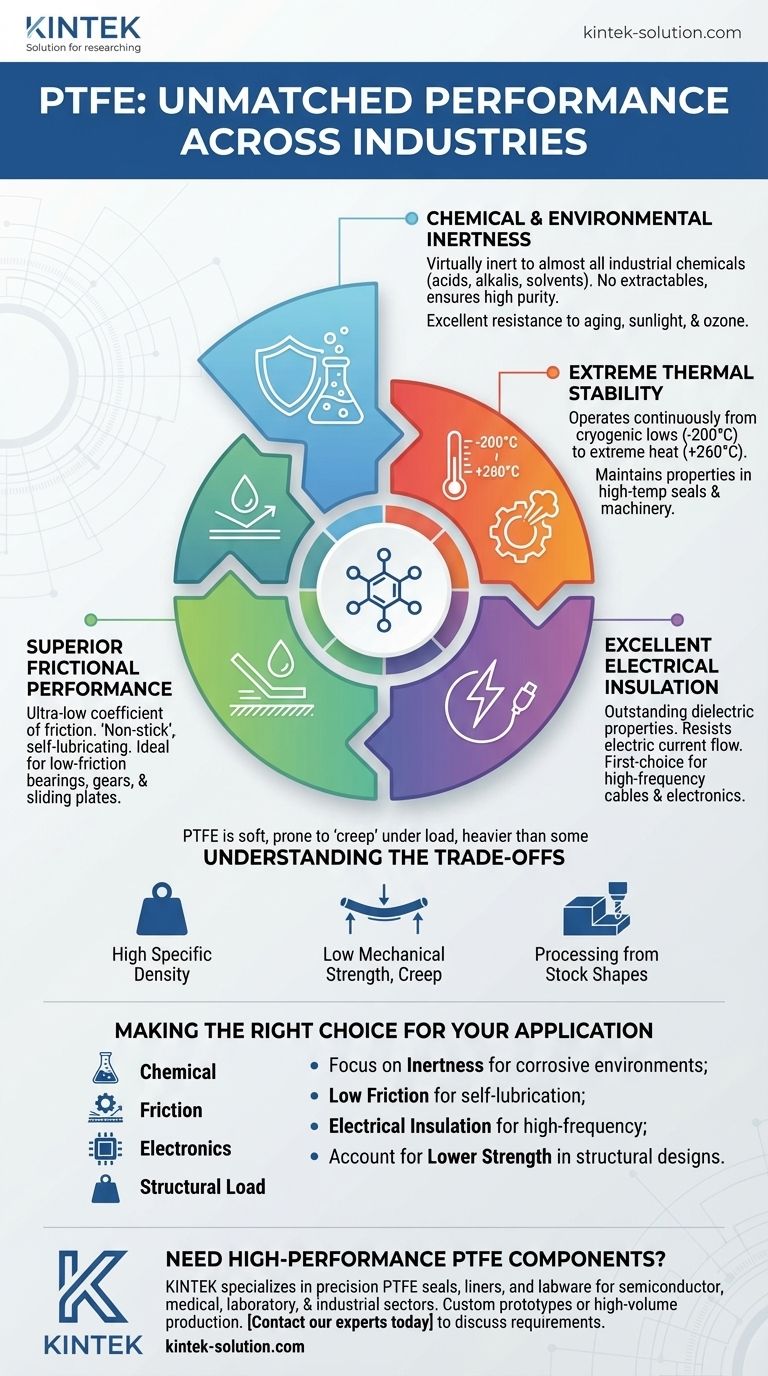

Unmatched Chemical and Environmental Inertness

The molecular structure of PTFE creates a highly stable and non-reactive material, making it suitable for use in harsh environments where other plastics would degrade.

Resisting Corrosive Chemicals

PTFE is virtually inert to almost all industrial chemicals, including strong acids, alkalis, solvents, and oxidizing agents.

This property makes it indispensable for components in the chemical processing industry, such as valve seals, gaskets, and tank linings.

Suitability for High-Purity Applications

The material has virtually no extractables, meaning it does not leach chemicals into its surrounding environment.

This purity is critical for applications in the food, pharmaceutical, and semiconductor industries, where contamination must be avoided at all costs.

Exceptional Aging Resistance

PTFE demonstrates outstanding resistance to environmental factors like sunlight and ozone. This ensures long-term stability and integrity for components used in exposed conditions.

Extreme Thermal Stability

PTFE maintains its key properties over an exceptionally wide temperature spectrum, outperforming most other polymers in both high and low-temperature scenarios.

A Vast Operating Temperature Range

PTFE can function effectively in continuous service from cryogenic lows of -200°C (-328°F) up to 260°C (500°F).

This allows it to be used in everything from aerospace components to high-temperature industrial processing equipment without losing its structural integrity or performance characteristics.

Reliability in High-Temperature Seals

Its ability to withstand high heat while remaining chemically inert makes it an ideal material for seals and components in engines, compressors, and other machinery operating at elevated temperatures.

Superior Frictional and Electrical Performance

Beyond its resilience, PTFE offers premier performance characteristics for both mechanical and electrical systems.

The "Non-Stick" Property

PTFE has one of the lowest coefficients of friction of any solid material, which gives it its signature non-stick and self-lubricating qualities.

This is invaluable for creating low-friction bearings, gears, and sliding plates that reduce wear and energy consumption in mechanical systems.

Excellent Electrical Insulation

The material possesses outstanding dielectric properties, meaning it is an excellent electrical insulator that resists the flow of electric current.

This makes it a first-choice material for insulating high-frequency cables and connectors in electronics and telecommunications, where signal integrity is paramount.

Understanding the Trade-offs

While its properties are exceptional, PTFE is not the ideal solution for every engineering problem. An objective assessment must include its limitations.

Low Mechanical Strength

Compared to other engineering plastics, PTFE is a relatively soft material. It can be prone to "creep," or slow deformation, when placed under a constant mechanical load.

High Specific Density

PTFE is heavier than many other common polymers. This can be a design constraint in applications where minimizing weight is a primary objective.

Processing from Stock Shapes

While PTFE is noted as being easy to process, this typically refers to machining parts from pre-made stock shapes like rods and sheets. It does not melt and flow like common thermoplastics, which can limit certain manufacturing methods.

Making the Right Choice for Your Application

Selecting the right material requires matching its properties to your primary engineering goal.

- If your primary focus is chemical processing: PTFE's near-total inertness makes it the superior choice for seals, gaskets, and linings that must handle corrosive materials.

- If your primary focus is reducing mechanical friction: Its ultra-low coefficient of friction is ideal for creating self-lubricating bearings and non-stick surfaces.

- If your primary focus is high-frequency electronics: Its excellent dielectric properties provide the stable electrical insulation required for critical components.

- If your primary focus is structural integrity under high load: You must account for PTFE's lower mechanical strength and consider either reinforced grades or alternative engineering plastics.

By understanding this unique profile of strengths and limitations, you can leverage PTFE to solve some of the most demanding engineering challenges.

Summary Table:

| Key Property | Why It Matters | Common Applications |

|---|---|---|

| Chemical Inertness | Resists virtually all chemicals, no leaching | Seals, gaskets, tank linings in chemical processing |

| Thermal Stability | Performs from -200°C to +260°C | High-temperature seals, aerospace components |

| Low Friction | Self-lubricating, non-stick surface | Bearings, gears, sliding plates |

| Electrical Insulation | Excellent dielectric properties | High-frequency cables, connectors |

Need high-performance PTFE components for a demanding application?

At KINTEK, we specialize in manufacturing precision PTFE components—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. Whether you require custom prototypes or high-volume production, our expertise ensures your components meet the highest standards of performance and reliability.

Contact our experts today to discuss your specific requirements and get a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers