The fundamental properties that make Polytetrafluoroethylene (PTFE) a superior material for seals and gaskets are its exceptional chemical inertness, wide thermal stability, and an extremely low coefficient of friction. These three characteristics allow PTFE to create a reliable and durable seal in demanding industrial environments where most other materials would quickly fail.

PTFE's value proposition is simple: it provides uncompromising performance in extreme chemical and thermal conditions. It is the material of choice when failure is not an option and the operational environment is too harsh for conventional elastomers or plastics.

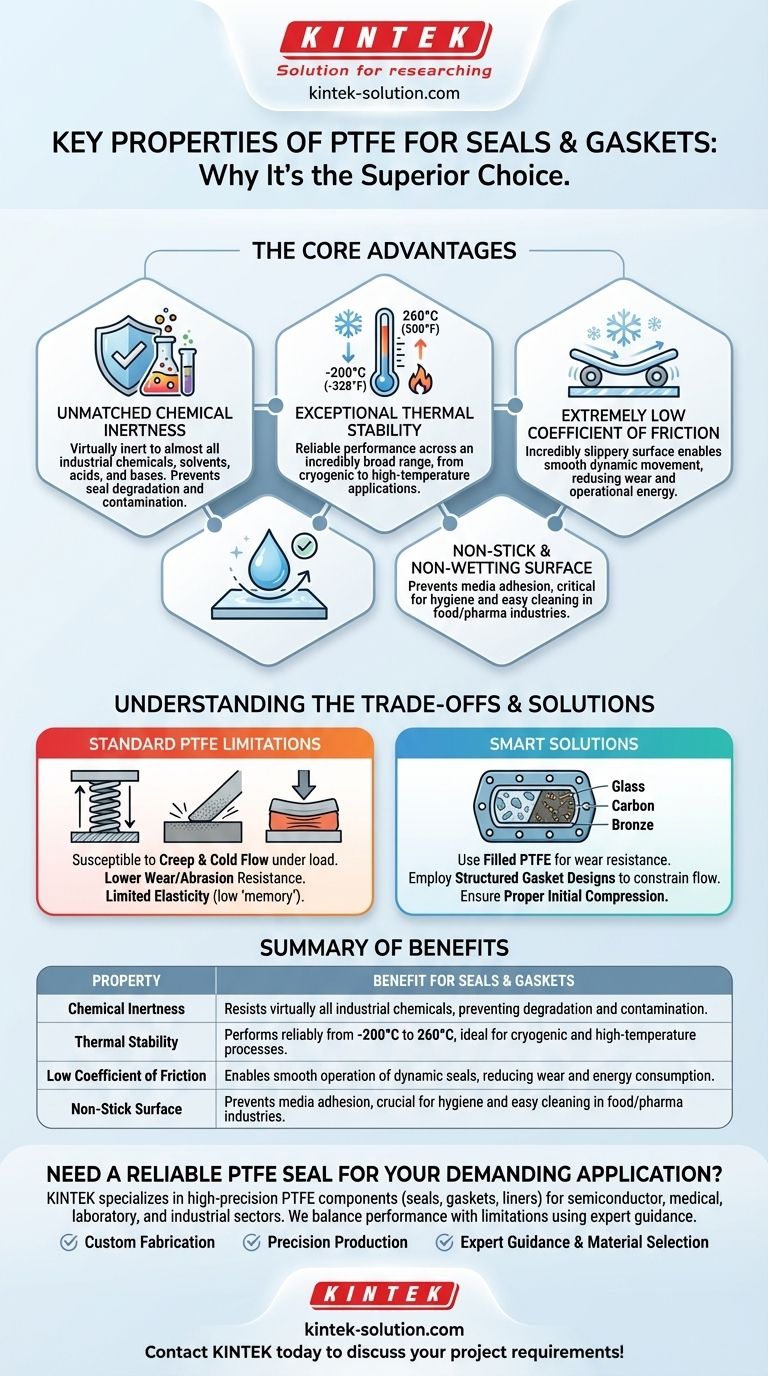

The Core Properties of PTFE for Sealing

To understand why PTFE is a foundational material in sealing technology, we must examine how its unique molecular structure translates into tangible performance benefits. Its composition of strong carbon-fluorine bonds is the source of its remarkable resilience.

Unmatched Chemical Inertness

PTFE is virtually inert to almost all industrial chemicals, solvents, acids, and bases. This non-reactive nature is its most significant advantage.

This property ensures the seal or gasket will not swell, degrade, or dissolve when exposed to aggressive media. This prevents both seal failure and contamination of the process fluid.

Exceptional Thermal Stability

PTFE performs reliably across an incredibly broad temperature range, typically from cryogenic levels of -200°C (-328°F) up to 260°C (500°F).

This makes it one of the most versatile sealing materials available, suitable for applications ranging from liquefied natural gas (LNG) processing to high-temperature chemical reactors.

Extremely Low Coefficient of Friction

PTFE has one of the lowest coefficients of friction of any solid material known, often compared to wet ice on wet ice. This makes its surface incredibly slippery.

This property is critical for dynamic seals, such as valve stems or hydraulic piston rings. It allows parts to move smoothly against the seal with minimal wear, reducing operational energy and extending the service life of the components.

Non-Stick and Non-Wetting Surface

The same properties that make PTFE chemically inert and low-friction also give it a non-stick, non-wetting (hydrophobic) surface.

This prevents media from adhering to the gasket, which is crucial for hygiene in food or pharmaceutical applications and ensures easier disassembly and cleaning of flanged joints.

Understanding the Trade-offs of Standard PTFE

While its core properties are outstanding, it's critical to understand the limitations of standard, or "virgin," PTFE. Recognizing these trade-offs is key to specifying the right material for your application.

Susceptibility to Creep and Cold Flow

The most significant limitation of pure PTFE is its tendency to "creep" or "cold flow." Under sustained compressive load, especially at elevated temperatures, the material can slowly deform and flow away from the pressure point.

This can cause a loss of bolt torque in a flanged connection, potentially compromising the integrity of the seal over time.

Lower Wear and Abrasion Resistance

Pure PTFE is a relatively soft material. In highly dynamic applications with abrasive media or high surface speeds, it can wear down more quickly than harder materials.

This is why various fillers (like glass, carbon, or bronze) are often added to PTFE to create compounds with significantly improved wear resistance and mechanical strength.

Limited Elasticity

Unlike rubber or elastomeric materials, PTFE has very little "memory" or elasticity. It does not spring back to its original shape after being compressed.

This means the initial installation and compression are critical to achieving a proper seal, as the material will not compensate for surface imperfections as readily as a flexible elastomer.

Making the Right Choice for Your Application

Your final material selection depends on balancing the elite properties of PTFE against its inherent limitations and the specific demands of your operating environment.

- If your primary focus is sealing aggressive chemicals: Virgin PTFE is often the best and safest choice due to its almost universal chemical inertness.

- If your application involves moving parts (dynamic sealing): PTFE's low friction is a major benefit, but consider a filled grade (e.g., carbon-filled PTFE) to improve wear resistance and service life.

- If you have a high-pressure static seal, especially at elevated temperatures: Be mindful of creep. Specify a filled PTFE or a structured gasket design that mechanically constrains the PTFE to prevent cold flow.

Ultimately, PTFE provides a high-performance sealing solution for the most challenging industrial applications.

Summary Table:

| Property | Benefit for Seals & Gaskets |

|---|---|

| Chemical Inertness | Resists virtually all industrial chemicals, preventing degradation and contamination. |

| Thermal Stability | Performs reliably from -200°C to 260°C, ideal for cryogenic and high-temperature processes. |

| Low Coefficient of Friction | Enables smooth operation of dynamic seals, reducing wear and energy consumption. |

| Non-Stick Surface | Prevents media adhesion, crucial for hygiene and easy cleaning in food/pharma industries. |

Need a Reliable PTFE Seal for Your Demanding Application?

PTFE's unique properties make it the material of choice when failure is not an option in harsh chemical or thermal environments. At KINTEK, we specialize in manufacturing high-precision PTFE components—including seals, gaskets, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors.

We understand the critical balance between PTFE's superior performance and its limitations like creep. Our experts can help you select the right material, whether virgin PTFE for ultimate chemical resistance or a filled compound for enhanced wear resistance and mechanical strength.

Let us provide the sealing solution you need:

- Custom Fabrication: From prototypes to high-volume orders.

- Precision Production: Ensuring uncompromising quality and performance.

- Expert Guidance: Selecting the optimal PTFE grade for your specific operating conditions.

Contact KINTEK today to discuss your project requirements and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- Why is PTFE suitable for cryogenic or high-temperature applications? Unmatched Thermal Stability from -450°F to 500°F

- What are the base characteristics of PTFE? Unlocking Extreme Performance in Friction, Temperature, and Chemical Resistance

- What is PTFE commonly known as and what are its unique properties? Unlock Unmatched Chemical & Thermal Resistance

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications