The key properties of PTFE that make it exceptionally suitable for medical use are its biocompatibility, chemical inertness, and an extremely low coefficient of friction. This unique combination means the material does not react with bodily tissues or fluids, resists aggressive sterilization chemicals, and allows medical devices to pass through the body with minimal tissue damage.

At its core, Polytetrafluoroethylene (PTFE) is trusted in medicine because it is one of the most non-reactive and stable materials known. Its inert nature ensures patient safety inside the body, while its unique physical properties enhance the performance and reliability of critical medical devices.

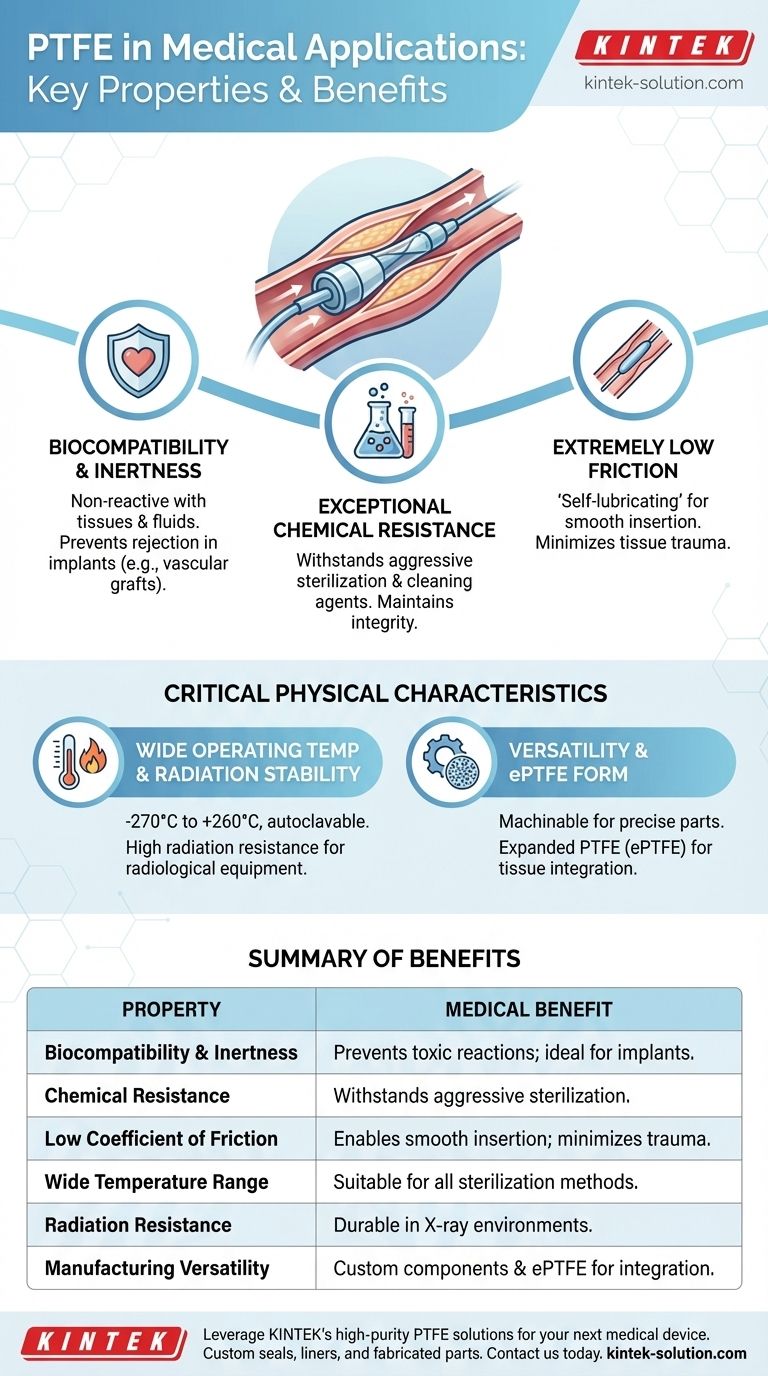

The Core Properties Driving Medical Adoption

To understand why PTFE is a cornerstone material in modern healthcare, we must examine the specific properties that directly impact patient safety and device function.

Absolute Biocompatibility and Inertness

PTFE is biologically inert, meaning it does not cause a toxic or immunological response when exposed to the body. It is non-reactive with bodily fluids and tissues, which is the single most important factor for any material used in implants.

This property prevents rejection and other adverse physiological side effects. As a result, PTFE is widely used for cardiovascular grafts, soft tissue regeneration patches, and ligament replacements.

Exceptional Chemical Resistance

The molecular structure of PTFE, defined by strong carbon-fluorine bonds, makes it resistant to nearly all chemicals. This is critical in a medical setting where devices are exposed to a wide range of substances, including aggressive cleaning agents and sterilization processes.

This resistance ensures the material's integrity and purity are maintained, which is vital for components in laboratory equipment, syringes, and other machinery that must remain uncontaminated.

Extremely Low Coefficient of Friction

PTFE has one of the lowest friction coefficients of any known solid, giving it a self-lubricating, "non-stick" quality. This property is crucial for devices that must move smoothly within or against sensitive biological tissues.

Applications like catheters, guidewires, and surgical sutures rely on this low-friction surface to minimize tissue trauma during insertion and use, improving patient comfort and procedural success.

Critical Physical and Thermal Characteristics

Beyond its core biocompatibility, PTFE's physical attributes make it a highly versatile and reliable engineering plastic for demanding medical environments.

Wide Operating Temperature Range

PTFE maintains its properties over an incredible thermal range, from -270°C to +260°C. Its high melting point (around 327°C) compared to other plastics is particularly important.

This thermal stability allows PTFE components to be sterilized using any method, including high-temperature steam autoclaving, without degrading or losing their shape and function.

High Radiation Resistance

This material exhibits a high resistance to radiation. This makes it a suitable choice for components used in radiological equipment, such as shielding elements in X-ray machines, where long-term exposure could degrade lesser materials.

Versatility in Manufacturing and Form

PTFE is not a single-form material. It can be easily machined from solid rods and tubes to create precise components like forceps and testing tools.

Furthermore, it can be processed into Expanded PTFE (ePTFE), which has a multi-microporous structure. This form is ideal for applications requiring tissue integration, such as artificial blood vessels and surgical patches.

Key Considerations for Medical Implementation

While PTFE's properties are impressive, its successful application in medicine depends on understanding its context and limitations.

Regulatory Compliance is Non-Negotiable

Not all PTFE is suitable for medical use. Only specific medical-grade resins that comply with stringent standards, such as those set by the FDA, can be used in medical devices and implants. This ensures the material meets the highest purity and safety requirements.

The Importance of Form Factor

The choice between solid PTFE and ePTFE is application-driven. A solid PTFE coating on a catheter provides a low-friction surface, while the porous structure of an ePTFE vascular graft is designed to encourage natural cell growth and integration with the body.

Making the Right Choice for Your Goal

Your specific medical application will determine which of PTFE's properties are most critical.

- If your primary focus is patient safety in implants: Prioritize PTFE's absolute biocompatibility and chemical inertness, which prevent rejection and material degradation over time.

- If your primary focus is device functionality and performance: Leverage its extremely low friction for applications like catheters and guidewires to ensure smooth and non-traumatic delivery.

- If your primary focus is equipment durability and reliability: Rely on its high chemical and thermal resistance for reusable tools and lab equipment that must withstand harsh sterilization and use cycles.

Ultimately, PTFE's distinct fusion of biological safety and high-performance physical characteristics makes it an indispensable material in advancing medical technology.

Summary Table:

| Key Property | Benefit in Medical Applications |

|---|---|

| Biocompatibility & Inertness | Prevents toxic reactions; ideal for implants like vascular grafts. |

| Chemical Resistance | Withstands aggressive sterilization; maintains material integrity. |

| Low Coefficient of Friction | Enables smooth insertion of catheters and guidewires, minimizing tissue trauma. |

| Wide Temperature Range | Suitable for all sterilization methods, including autoclaving. |

| Radiation Resistance | Durable in radiological equipment environments. |

| Manufacturing Versatility | Can be machined into precise components or expanded (ePTFE) for tissue integration. |

Leverage PTFE's critical properties for your next medical device.

At KINTEK, we specialize in manufacturing high-purity, medical-grade PTFE components—from seals and liners to custom labware and complex fabricated parts. Our expertise ensures your devices meet the stringent safety and performance requirements of the medical, semiconductor, and laboratory industries.

We offer custom fabrication from prototypes to high-volume orders, prioritizing precision and compliance.

Contact KINTEK today to discuss how our PTFE solutions can enhance your product's safety, reliability, and performance.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support