At its core, Polytetrafluoroethylene (PTFE) is a material of extremes, making it indispensable in demanding industrial environments. Its value stems from a unique combination of properties, most notably its near-total chemical resistance, an exceptionally low coefficient of friction, stability across a vast temperature range, and superior electrical insulation.

PTFE's industrial advantage is not just one standout feature, but the rare synergy of these properties. It allows the material to perform reliably in harsh conditions where nearly all other plastics and even many metals would quickly fail.

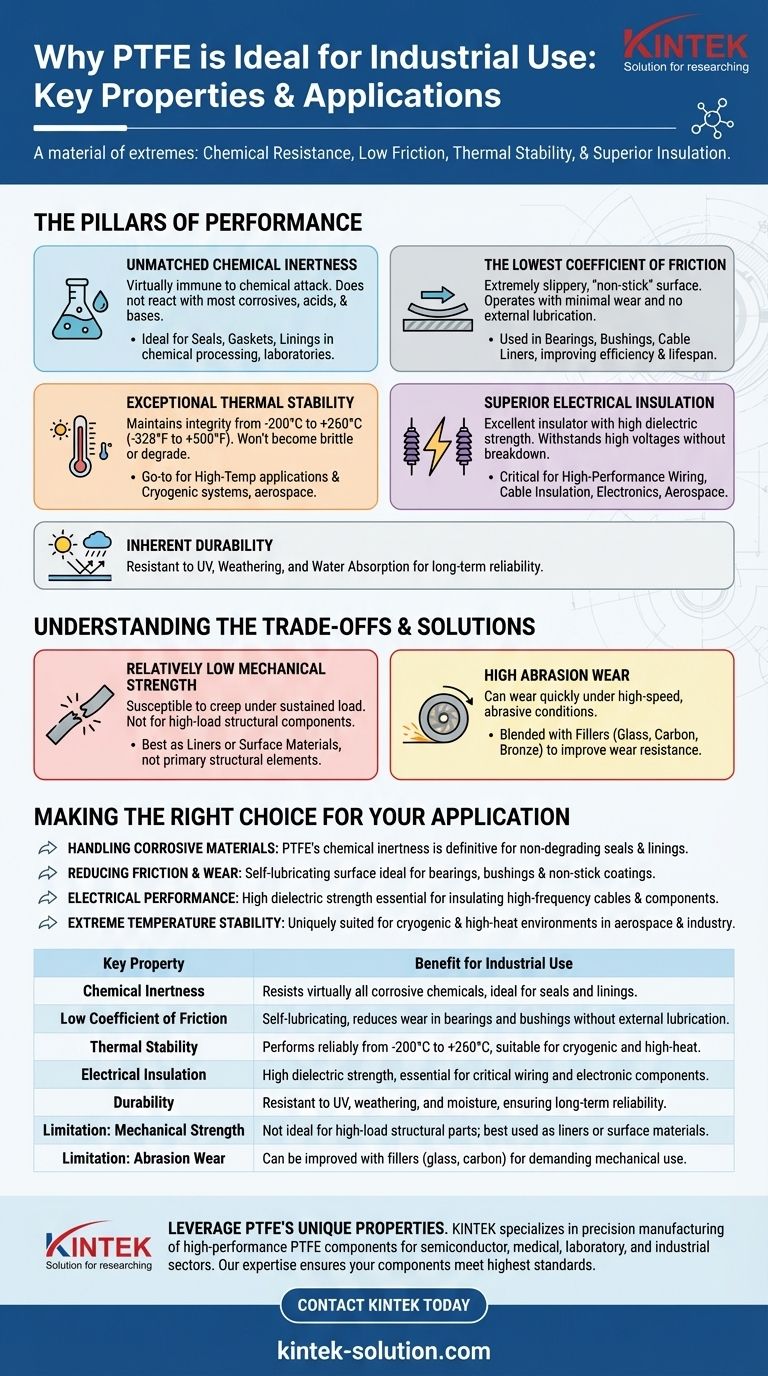

The Pillars of Performance: Deconstructing PTFE's Key Properties

To understand why PTFE is specified for critical applications, we must examine the individual properties that contribute to its robust performance.

Unmatched Chemical Inertness

PTFE is virtually immune to chemical attack. It does not react with the vast majority of corrosive chemicals, acids, and bases.

This makes it an ideal material for seals, gaskets, and linings in chemical processing plants, laboratories, and any application involving aggressive substances.

The Lowest Coefficient of Friction

Of all known solid materials, PTFE has one of the lowest coefficients of friction. This gives it an extremely slippery, "non-stick" surface.

In industrial settings, this means components like bearings, bushings, and cable liners can operate with minimal wear and without external lubrication, increasing efficiency and component lifespan.

Exceptional Thermal Stability

PTFE maintains its integrity and core properties across an incredibly wide temperature range, typically from -200°C to +260°C (-328°F to +500°F).

This stability makes it the go-to material for both high-temperature applications and cryogenic systems, as it will not become brittle at low temperatures or degrade at high heat.

Superior Electrical Insulation

PTFE is an excellent electrical insulator with high dielectric strength, meaning it can withstand very high voltages without breaking down.

This property is critical for high-performance wiring, cable insulation, and components in the electronics and aerospace industries where electrical reliability is non-negotiable.

Inherent Durability and Resilience

Beyond its primary characteristics, PTFE is highly resistant to degradation from UV radiation, weathering, and water absorption.

This ensures long-term reliability for components used outdoors or in environments with fluctuating conditions, as the material will not degrade or change its dimensions due to moisture.

Understanding the Trade-offs and Limitations

No material is perfect. While PTFE's properties are exceptional, understanding its limitations is critical for proper application.

Relatively Low Mechanical Strength

Compared to other engineering plastics, PTFE is relatively soft and has lower tensile strength. It can be susceptible to creep, which is slow deformation under a sustained load.

Because of this, pure PTFE is generally not suitable for high-load structural components. It excels as a liner or a surface material, not as a primary structural element.

High Abrasion Wear

While PTFE's low friction prevents wear in sliding applications, it can wear quickly when subjected to high-speed, abrasive materials.

To counteract this, PTFE is often blended with fillers like glass, carbon, or bronze to create compounds that significantly improve wear resistance for more demanding mechanical applications.

Processing Complexity

PTFE's high melting point and high melt viscosity make it difficult to process using conventional thermoplastic methods like injection molding.

It typically requires specialized techniques such as compression molding and sintering, which can impact manufacturing costs and design complexity.

Making the Right Choice for Your Application

Selecting PTFE should be a deliberate decision based on the primary challenge you need to solve.

- If your primary focus is handling corrosive materials: PTFE's chemical inertness makes it the definitive choice for gaskets, seals, and linings that will not degrade.

- If your primary focus is reducing friction and wear: Its self-lubricating surface is ideal for bearings, bushings, and non-stick coatings where smooth movement is critical.

- If your primary focus is electrical performance: Its high dielectric strength makes it essential for insulating high-frequency cables and critical electronic components.

- If your primary focus is extreme temperature stability: Its ability to perform in both cryogenic and high-heat environments makes it uniquely suited for aerospace and specialized industrial processes.

By understanding these core properties and their inherent trade-offs, you can confidently specify PTFE for applications that demand the highest levels of performance and reliability.

Summary Table:

| Key Property | Benefit for Industrial Use |

|---|---|

| Chemical Inertness | Resists virtually all corrosive chemicals, ideal for seals and linings. |

| Low Coefficient of Friction | Self-lubricating, reduces wear in bearings and bushings without external lubrication. |

| Thermal Stability | Performs reliably from -200°C to +260°C, suitable for cryogenic and high-heat applications. |

| Electrical Insulation | High dielectric strength, essential for critical wiring and electronic components. |

| Durability | Resistant to UV, weathering, and moisture, ensuring long-term reliability. |

| Limitation: Mechanical Strength | Not ideal for high-load structural parts; best used as liners or surface materials. |

| Limitation: Abrasion Wear | Can be improved with fillers (glass, carbon) for demanding mechanical use. |

Leverage PTFE's unique properties for your most demanding applications. KINTEK specializes in the precision manufacturing of high-performance PTFE components—including custom seals, liners, labware, and more—for the semiconductor, medical, laboratory, and industrial sectors. Whether you need prototypes or high-volume production, our expertise ensures your components meet the highest standards of chemical resistance, thermal stability, and electrical performance. Contact KINTEB today to discuss how our PTFE solutions can enhance your product's reliability and longevity.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support