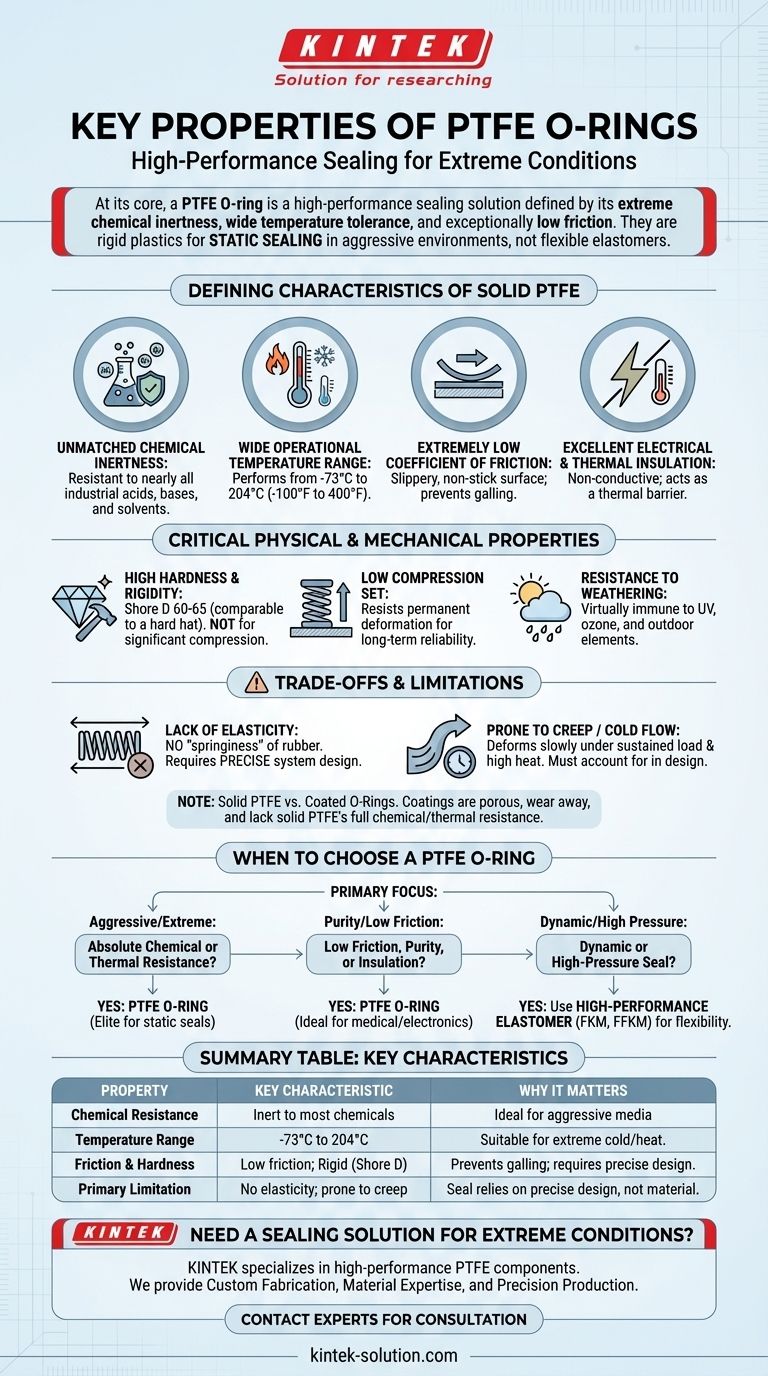

At its core, a PTFE O-ring is a high-performance sealing solution defined by its extreme chemical inertness, wide temperature tolerance, and exceptionally low friction. Unlike common elastomeric (rubber) O-rings, those made from solid Polytetrafluoroethylene (PTFE) are rigid plastics, which fundamentally changes how and where they should be used.

The central takeaway is that PTFE O-rings are specialist components designed for static sealing in chemically aggressive or high-temperature environments. Their unparalleled material resistance comes at the cost of the flexibility and compressibility found in traditional rubber seals, making proper gland design absolutely critical.

The Defining Characteristics of Solid PTFE

The value of a PTFE O-ring comes from the inherent properties of the material itself. These characteristics make it a problem-solver for applications where other materials would quickly fail.

Unmatched Chemical Inertness

A key advantage of PTFE is its resistance to nearly all industrial chemicals. It is inert when exposed to most acids, bases, solvents, and other aggressive substances, making it invaluable in chemical processing, pharmaceutical, and petrochemical industries.

Wide Operational Temperature Range

PTFE maintains its integrity across a vast temperature spectrum, typically from -73°C to 204°C (-100°F to 400°F). This allows it to function effectively in both cryogenic applications and high-heat environments where conventional elastomers would become brittle or degrade.

Extremely Low Coefficient of Friction

Often recognized by its brand name Teflon, PTFE has one of the lowest coefficients of friction of any solid material. This creates a slippery, non-stick surface ideal for preventing galling during assembly and for applications where smooth movement is required.

Excellent Electrical and Thermal Insulation

PTFE does not conduct electricity, making it an excellent choice for sealing electrical components or enclosures where insulation is critical. It also has low thermal conductivity, allowing it to act as a thermal break between components.

Critical Physical and Mechanical Properties

Understanding the mechanical behavior of PTFE is crucial for successful implementation. It does not behave like a rubber O-ring.

High Hardness and Rigidity

PTFE O-rings have a hardness of 60-65 on the Shore D scale, which is comparable to a hard hat. This confirms they are rigid plastics, not soft elastomers (which are measured on the Shore A scale). They are not designed to be compressed significantly to create a seal.

Low Compression Set

This property means that PTFE resists being permanently deformed after a compressive force is removed. In a properly designed static seal, this ensures long-term reliability without the material "packing out" and losing its sealing force.

Resistance to Weathering

PTFE is virtually immune to degradation from UV radiation, ozone, and general weathering. This makes it highly suitable for outdoor applications or those with exposure to the elements.

Understanding the Trade-offs and Limitations

While powerful, PTFE is not a universal solution. Its limitations are as important to understand as its strengths.

Lack of Elasticity

The single most important limitation is that PTFE is not elastic. It does not have the "springiness" of rubber. This means it cannot compensate for imperfections in sealing surfaces or tolerate significant variations in gland dimensions. The seal relies on precise system design, not material compliance.

Prone to Creep or "Cold Flow"

Under a constant, sustained load (especially at elevated temperatures), PTFE can slowly and permanently deform. This phenomenon, known as creep or cold flow, can lead to a loss of sealing pressure over time if not accounted for in the design.

A Note on PTFE-Coated O-Rings

It is important to distinguish solid PTFE O-rings from standard elastomeric O-rings that have a thin PTFE coating. A coating is primarily used for color identification or as a dry lubricant to ease installation. However, this coating is porous and can wear away easily, exposing the underlying rubber. It does not provide the same chemical or thermal resistance as a solid PTFE ring.

When to Choose a PTFE O-Ring

Selecting the right seal requires matching the material to the engineering goal. Use this guide to make an informed decision.

- If your primary focus is absolute chemical or thermal resistance: A solid PTFE O-ring is an elite choice for static applications involving aggressive media or extreme temperatures where elastomers would fail.

- If your primary focus is low friction, purity, or insulation: PTFE's non-stick surface and inert nature are ideal for medical, food-grade, or sensitive electronic applications.

- If your primary focus is a dynamic or high-pressure seal: You should likely use a high-performance elastomer (like FKM or FFKM), as they provide the necessary flexibility and resilience that rigid PTFE lacks.

Ultimately, choosing a PTFE O-ring is a deliberate engineering decision to prioritize material survivability over mechanical flexibility.

Summary Table:

| Property | Key Characteristic | Why It Matters |

|---|---|---|

| Chemical Resistance | Inert to nearly all acids, bases, and solvents. | Ideal for aggressive chemical processing, pharmaceutical, and petrochemical applications. |

| Temperature Range | Performs from -73°C to 204°C (-100°F to 400°F). | Suitable for both cryogenic and high-heat environments where elastomers fail. |

| Friction & Hardness | Extremely low friction; rigid (Shore D 60-65). | Prevents galling, but requires precise gland design due to lack of elasticity. |

| Primary Limitation | Not elastic; prone to creep under sustained load. | Seal relies on precise system design, not material compliance. |

Need a sealing solution for extreme conditions?

PTFE O-rings are specialist components, and their success hinges on precision manufacturing and correct application. At KINTEK, we specialize in fabricating high-performance PTFE components—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors.

We provide:

- Custom Fabrication: From prototypes to high-volume production runs.

- Material Expertise: Ensuring your PTFE seals meet exact chemical, thermal, and mechanical requirements.

- Precision Production: Guaranteeing the dimensional accuracy critical for PTFE's success.

Let's engineer the perfect seal for your application. Contact our experts today for a consultation.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers