In short, PTFE bellows are exceptionally suited for demanding environments due to their unique combination of chemical inertness, a wide operating temperature range, and an extremely low-friction, non-stick surface. These core properties allow them to function reliably in applications involving corrosive chemicals, extreme temperatures, and sensitive processes where purity is paramount.

The decision to use PTFE bellows is rarely about a single feature. It is about achieving operational resilience. Their properties work in concert to solve the fundamental challenges of material degradation, contamination, and mechanical stress in aggressive industrial environments.

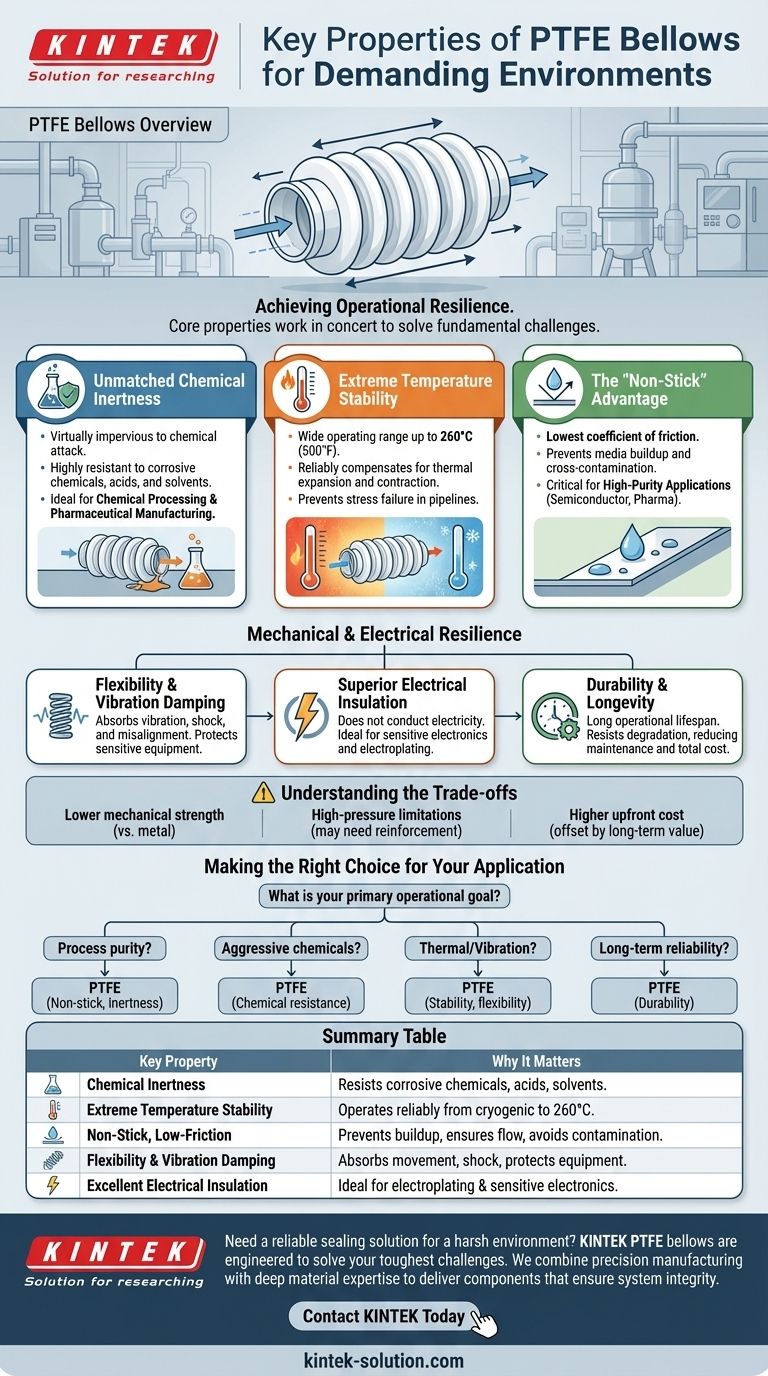

The Core Pillars of PTFE Performance

The primary value of Polytetrafluoroethylene (PTFE) comes from three defining characteristics that set it apart from other materials.

Unmatched Chemical Inertness

PTFE is virtually impervious to chemical attack. It is highly resistant to almost all industrial chemicals, acids, and solvents.

This makes PTFE bellows the default choice for systems that handle corrosive or chemically aggressive media, such as in chemical processing, pharmaceutical manufacturing, and coating technology.

Extreme Temperature Stability

PTFE bellows maintain their integrity and performance across a very wide operating temperature range, with a maximum continuous service temperature of 260°C (500°F).

This allows them to reliably compensate for thermal expansion and contraction in pipelines that experience large temperature variations, preventing stress and potential failure.

The "Non-Stick" Advantage

PTFE has the lowest coefficient of friction of any solid material. Its surface is designed to repel other materials, preventing media from sticking or building up.

This non-stick property is critical for ensuring efficient fluid flow, reducing the risk of blockages, and preventing cross-contamination in high-purity applications like semiconductor and pharmaceutical manufacturing.

Mechanical and Electrical Resilience

Beyond its core chemical and thermal properties, the design and material of PTFE bellows provide crucial mechanical and electrical benefits.

Inherent Flexibility and Vibration Damping

The convoluted shape of the bellows provides high flexibility, allowing it to absorb vibration, shock, and system misalignment.

This function protects sensitive equipment, reduces noise, and compensates for movement in complex piping systems, extending the lifespan of the entire assembly.

Superior Electrical Insulation

PTFE possesses excellent electrical insulation properties. It does not conduct electricity, making it an ideal material for specific processes.

This characteristic is particularly valuable in applications like electroplating or in the manufacturing of sensitive electronics, where stray electrical currents could disrupt processes or damage components.

Durability and Longevity

The robust construction and inherent resistance of PTFE to chemical and environmental degradation contribute to a long operational lifespan.

This durability reduces the need for frequent maintenance and replacement, lowering the total cost of ownership over the life of the equipment.

Understanding the Trade-offs

While its properties are exceptional, PTFE is not the universally perfect material for every scenario. Understanding its limitations is key to proper specification.

Mechanical Strength Limitations

Compared to metal bellows, PTFE has a lower tensile strength and is more susceptible to deformation under high mechanical load. Its strength is in its chemical resilience, not its brute force resistance.

Considerations for High-Pressure Systems

In high-pressure applications, unreinforced PTFE bellows may not be suitable. Often, they require external reinforcement rings or are integrated into more complex assemblies to handle significant internal pressures.

Cost vs. Lifecycle Value

The upfront cost of PTFE components can be higher than that of alternatives like rubber or certain metals. However, this is often offset by its dramatically longer lifespan and reduced maintenance requirements in corrosive or high-temperature environments.

Making the Right Choice for Your Application

Selecting the right material is about aligning its properties with your primary operational goal.

- If your primary focus is process purity and preventing contamination: The non-stick surface and chemical inertness of PTFE make it the superior choice.

- If your primary focus is handling highly aggressive chemicals: PTFE's near-total chemical resistance ensures system integrity where most other materials would fail.

- If your primary focus is managing thermal expansion and vibration: The combination of temperature stability and mechanical flexibility allows PTFE bellows to absorb dynamic stresses effectively.

- If your primary focus is long-term reliability in harsh environments: PTFE's durability and resistance to chemical, thermal, and moisture degradation lead to lower maintenance and a longer service life.

By understanding these distinct advantages, you can confidently specify PTFE bellows for applications where performance and reliability are non-negotiable.

Summary Table:

| Key Property | Why It Matters for Demanding Environments |

|---|---|

| Chemical Inertness | Resists virtually all corrosive chemicals, acids, and solvents. |

| Extreme Temperature Stability | Operates reliably from cryogenic up to 260°C (500°F). |

| Non-Stick, Low-Friction Surface | Prevents media buildup, ensures flow, and avoids contamination. |

| Flexibility & Vibration Damping | Absorbs movement, shock, and misalignment to protect equipment. |

| Excellent Electrical Insulation | Ideal for electroplating and sensitive electronics manufacturing. |

Need a reliable sealing solution for a harsh environment?

PTFE bellows from KINTEK are engineered to solve your toughest challenges in semiconductor, pharmaceutical, chemical processing, and other specialized industries. We combine precision manufacturing with deep material expertise to deliver components that ensure system integrity, prevent contamination, and extend equipment lifespan.

Whether you require a standard part or a custom-fabricated solution from prototype to high-volume production, we are here to help.

Contact KINTEK today to discuss your specific application requirements and discover the right PTFE bellow solution for you.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What are some important physical property values for PTFE? Master Its Extreme Performance for Demanding Applications

- What is the hardness range of PTFE on the Shore D scale? Leveraging Its Softness for Superior Performance

- Why is PTFE considered a significant discovery? A Material That Revolutionized Industry

- How is PTFE used in industrial processes? Maximize Safety and Efficiency

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications