When selecting a material for bushings and thrust washers, the choice between PTFE and nylon comes down to a trade-off between ultimate performance and cost-effectiveness. PTFE (Polytetrafluoroethylene) is the superior material for applications demanding extremely low friction, high load capacity, and near-universal chemical resistance. Nylon offers a strong, cost-effective alternative with good mechanical properties and self-lubrication for more general-purpose use.

The core decision hinges on your operating environment. PTFE is the definitive choice for harsh chemical, high-load, or critical low-friction applications, while nylon serves as a reliable workhorse for moderate-load scenarios where cost is a significant factor.

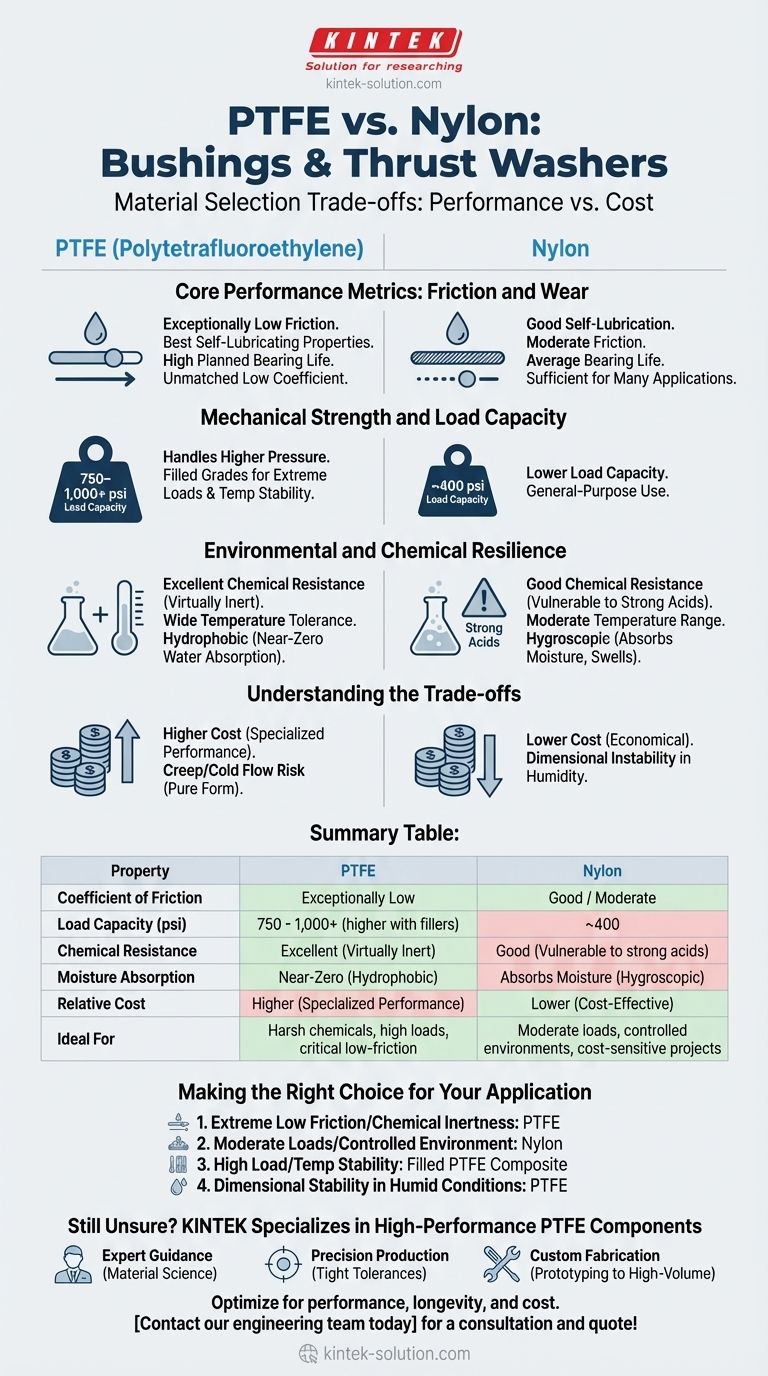

Core Performance Metrics: Friction and Wear

The primary function of a bushing or washer is to reduce friction and manage wear between moving parts. How each material achieves this is a key differentiator.

PTFE's Unmatched Low Friction

PTFE has an exceptionally low coefficient of friction, one of the lowest of any known solid material. This gives it the best self-lubricating properties available in a polymer.

This inherent slipperiness means it provides smooth, reliable operation even without external lubricants, significantly reducing wear and extending the component's service life.

Nylon's Good Self-Lubrication

Nylon also has a moderately low coefficient of friction and is considered a good self-lubricating material.

While it cannot match the performance of PTFE, it is more than sufficient for many applications where friction is a concern but not the single most critical performance variable.

Longevity and Bearing Life

These friction properties directly impact the planned lifespan of the component. Due to its superior wear resistance, PTFE generally offers a high planned bearing life.

Nylon, while robust, is typically rated for an average bearing life in comparison.

Mechanical Strength and Load Capacity

The ability to withstand force without deforming is critical for any bushing or washer. Here, the differences become more pronounced.

Load Handling Capabilities

PTFE demonstrates a clear advantage in its ability to handle pressure. Standard PTFE can manage loads between 750–1,000 psi.

In contrast, nylon has a lower load capacity, typically around 400 psi. This makes PTFE a better choice for higher-stress applications.

Enhanced Strength with Fillers

For extreme conditions, filled PTFE is often used. Adding fillers like glass, carbon, or graphite dramatically increases its strength and stability under extreme loads and high temperatures while retaining low-friction properties.

Environmental and Chemical Resilience

The operational environment often dictates the material choice, as chemical exposure and temperature can quickly degrade a component.

Chemical Resistance: A Clear Winner

PTFE is renowned for its excellent chemical resistance. It is virtually inert and non-reactive with almost all industrial chemicals and solvents.

Nylon has good chemical resistance but is vulnerable to strong acids and other specific chemical agents that do not affect PTFE.

Temperature Tolerance

PTFE is known for its ability to perform reliably across a very wide temperature range, maintaining its properties in both high and low-temperature environments.

Water Interactivity and Stability

A crucial difference is how each material interacts with moisture. PTFE is hydrophobic and has near-zero water absorption.

Nylon, on the other hand, is hygroscopic, meaning it will absorb moisture from the air. This can cause it to swell, affecting the dimensional tolerances of a precision part like a bushing.

Understanding the Trade-offs

No material is perfect for every situation. Selecting the right one requires an objective look at their inherent limitations.

The Cost Factor

The most significant trade-off is often cost. Nylon is a widely produced and more economical material, making it an attractive choice for high-volume or cost-sensitive projects.

PTFE is a more specialized, high-performance polymer, and its manufacturing process makes it a more expensive material.

Dimensional Stability in Humid Environments

As mentioned, nylon's tendency to absorb moisture is a critical design constraint. In applications requiring tight tolerances or operating in humid conditions, the potential for swelling must be accounted for or avoided by choosing PTFE.

Creep and Cold Flow in PTFE

While strong, pure PTFE can be susceptible to "creep" or "cold flow," where the material slowly deforms over time under a constant load. This is why filled PTFE grades are often specified for high-load structural applications, as the fillers provide a rigid matrix that prevents this deformation.

Making the Right Choice for Your Application

Your final decision should be guided by the most critical demands of your specific use case.

- If your primary focus is extreme low friction or chemical inertness: PTFE is the only logical choice, especially where aggressive chemicals are present or external lubrication is impossible.

- If your primary focus is moderate loads in a controlled environment: Nylon provides an excellent balance of mechanical performance and cost-effectiveness.

- If your primary focus is high load and temperature stability: A filled PTFE composite is the superior option, combining PTFE's low friction with enhanced mechanical strength and creep resistance.

- If your primary focus is dimensional stability in humid conditions: PTFE is the safer choice due to its near-zero water absorption, ensuring consistent clearances and performance.

Understanding these core trade-offs between resilience, load capacity, and cost empowers you to select the precise material for optimal performance and longevity.

Summary Table:

| Property | PTFE | Nylon |

|---|---|---|

| Coefficient of Friction | Exceptionally Low | Good / Moderate |

| Load Capacity (psi) | 750 - 1,000+ (higher with fillers) | ~400 |

| Chemical Resistance | Excellent (Virtually Inert) | Good (Vulnerable to strong acids) |

| Moisture Absorption | Near-Zero (Hydrophobic) | Absorbs Moisture (Hygroscopic) |

| Relative Cost | Higher (Specialized Performance) | Lower (Cost-Effective) |

| Ideal For | Harsh chemicals, high loads, critical low-friction | Moderate loads, controlled environments, cost-sensitive projects |

Still Unsure Which Material is Best for Your Bushing or Thrust Washer?

At KINTEK, we specialize in manufacturing high-performance PTFE components, including custom bushings, seals, and thrust washers. Our expertise helps customers in the semiconductor, medical, laboratory, and industrial sectors navigate these exact material selection challenges.

We provide:

- Expert Guidance: Leverage our material science knowledge to select the optimal PTFE grade (including filled composites for high strength) or nylon for your specific operating environment.

- Precision Production: Ensure your components meet exact dimensional tolerances and performance requirements, critical for applications where moisture absorption or creep can cause failure.

- Custom Fabrication: From prototyping to high-volume orders, we tailor the solution to your needs.

Let us help you optimize for performance, longevity, and cost. Contact our engineering team today for a consultation and quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs