At their core, PTFE backup rings are defined by four key material properties: an extremely low coefficient of friction, near-universal chemical resistance, a vast operating temperature range, and excellent dielectric strength. Their primary function in a sealing system is to provide mechanical support and prevent a softer, primary seal (like an O-ring) from extruding into clearance gaps under high pressure.

While PTFE's inherent characteristics are impressive, its true value in a sealing application is mechanical. The material's primary job as a backup ring is to be a rigid barrier, preventing the failure of a softer seal under pressure. Understanding how its unique properties serve this specific function is the key to proper selection.

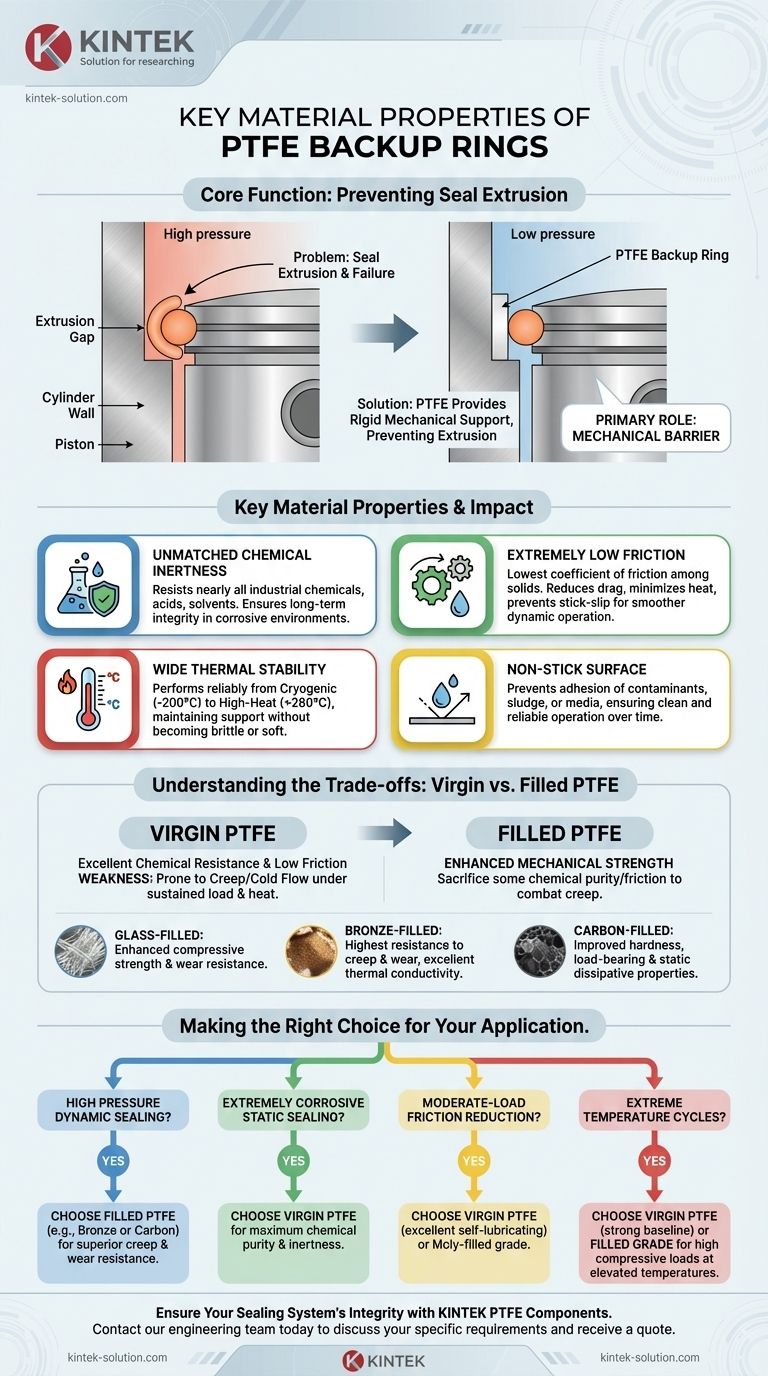

The Core Function: Preventing Seal Extrusion

Before examining the material properties in detail, it's critical to understand why backup rings are used. They are support components, not primary seals.

The Problem of Clearance Gaps

In any high-pressure system, there is a small gap (the "extrusion gap") between moving and stationary parts, such as a piston and a cylinder wall.

Under high pressure, a soft elastomeric seal like an O-ring can be forced into this gap. This process, known as extrusion, quickly shreds and destroys the seal, leading to catastrophic failure.

How PTFE Provides Mechanical Support

A PTFE backup ring is installed alongside the O-ring, typically on the low-pressure side. Because PTFE is much more rigid than the elastomer, it physically blocks the extrusion gap.

The ring does not seal pressure itself; it acts as a retaining wall, allowing the O-ring to maintain its shape and function effectively at pressures far higher than it could withstand on its own.

Key Material Properties and Their Impact

Each of PTFE's signature properties contributes directly to its performance as a backup ring in demanding environments.

Unmatched Chemical Inertness

PTFE is resistant to nearly all industrial chemicals, acids, and solvents. This makes it the default choice for applications involving corrosive media where an elastomer would quickly degrade.

This chemical stability ensures the backup ring will not swell, soften, or break down, maintaining its mechanical integrity regardless of the fluid or gas in the system.

Extremely Low Friction

PTFE has one of the lowest coefficients of friction of any solid material, often compared to wet ice on wet ice. This is crucial in dynamic applications where parts are in motion.

A low-friction backup ring reduces drag, minimizes heat generation, and prevents stick-slip behavior, leading to smoother operation and longer service life for the entire sealing assembly. Its self-lubricating nature is a major benefit.

Wide Thermal Stability

PTFE performs reliably across an exceptionally broad temperature range, typically from -200°C to +260°C (-328°F to +500°F).

This allows it to provide consistent mechanical support in systems that experience extreme temperature cycles, from cryogenic applications to high-heat industrial processes, without becoming brittle or soft.

Non-Stick Surface

Almost no substances will adhere to a PTFE surface. In a sealing system, this non-stick property prevents contaminants, sludge, or system media from building up on the ring, ensuring clean and reliable operation over time.

Understanding the Trade-offs: Virgin vs. Filled PTFE

While pure (virgin) PTFE has incredible properties, it has one significant mechanical weakness: a tendency to deform under sustained load, a phenomenon known as creep or cold flow.

The Challenge of Creep

Under constant pressure, especially at elevated temperatures, virgin PTFE can slowly deform and lose its shape. This can compromise its ability to effectively block the extrusion gap, reducing the reliability of the seal.

The Solution: The Role of Fillers

To combat creep and enhance specific mechanical properties, PTFE is often blended with filler materials. This creates a composite material known as filled PTFE.

Common fillers include glass fibers, bronze, carbon, and molybdenum disulfide (Moly). Each additive alters the base properties of the PTFE in a predictable way.

How Fillers Modify Properties

Adding fillers introduces a trade-off: you typically sacrifice some of the pure chemical resistance or the ultra-low friction of virgin PTFE to gain a significant improvement in mechanical strength.

- Glass-filled PTFE offers enhanced compressive strength and wear resistance.

- Bronze-filled PTFE provides excellent thermal conductivity and the highest resistance to creep and wear, making it ideal for high-load dynamic applications.

- Carbon-filled PTFE improves hardness and load-bearing capabilities while also providing static dissipative properties.

Making the Right Choice for Your Application

Selecting the correct PTFE material is a matter of matching the material's strengths to the primary demands of your system.

- If your primary focus is dynamic sealing with high pressure: Choose a filled PTFE, like bronze or carbon-filled, for superior creep and wear resistance.

- If your primary focus is static sealing in an extremely corrosive environment: Virgin PTFE is often the best choice, as it offers maximum chemical purity and inertness.

- If your primary focus is reducing friction in a moderate-load application: Virgin PTFE's self-lubricating properties are excellent, but a Moly-filled grade can further reduce the coefficient of friction.

- If your primary focus is operating across extreme temperature cycles: Virgin PTFE is a strong baseline, but consider a filled grade if high compressive loads are also a factor at elevated temperatures.

By matching the specific grade of PTFE to your operational demands, you ensure the integrity and longevity of your entire sealing system.

Summary Table:

| Key Property | Why It Matters for Backup Rings |

|---|---|

| Chemical Inertness | Resists corrosive media, ensuring mechanical integrity in harsh environments. |

| Low Coefficient of Friction | Reduces drag and heat in dynamic applications, enabling smoother operation. |

| Wide Temperature Range | Provides consistent support from cryogenic (-200°C) to high-heat (+260°C) conditions. |

| Non-Stick Surface | Prevents contaminant buildup, ensuring reliable long-term performance. |

| Fillers (e.g., Glass, Bronze) | Enhance creep resistance and wear for high-load applications (trade-off: slightly reduced chemical purity). |

Ensure Your Sealing System's Integrity with KINTEK PTFE Components

PTFE backup rings are critical for preventing seal failure under high pressure, but selecting the right material—whether virgin PTFE for maximum chemical resistance or a filled grade for superior mechanical strength—is essential for your application's success.

KINTEK specializes in the precision manufacturing of high-performance PTFE components, including custom backup rings, for the most demanding environments in the semiconductor, medical, laboratory, and industrial sectors.

We understand that a one-size-fits-all approach doesn't work. Our experts will help you select or custom-fabricate the ideal PTFE solution, from prototypes to high-volume orders, to ensure your sealing systems operate reliably under extreme pressure, temperature, and chemical exposure.

Let's optimize your sealing assembly. Contact our engineering team today to discuss your specific requirements and receive a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What materials can PTFE O-rings be produced with? From Virgin PTFE to Enhanced Compounds

- What types of applications are PTFE / FEP / PFA lined pipes suitable for? Handle Extreme Corrosive Fluids Safely

- What is a PTFE envelope gasket? A Hybrid Seal for Superior Chemical Resistance

- How do PTFE envelope gaskets address the limitations of pure PTFE gaskets? Enhance Sealing Performance

- Why is Teflon packing popular in chemical and heat-sensitive environments? For Unmatched Chemical Resistance and Low Friction

- What are the key properties of PTFE oil seals? Superior Performance for Extreme Environments

- What does the leakage rate indicate about PTFE gaskets? Understanding the Sealing Performance Trade-off

- What is PV value and why is it important for PTFE seals? Prevent Premature Seal Failure