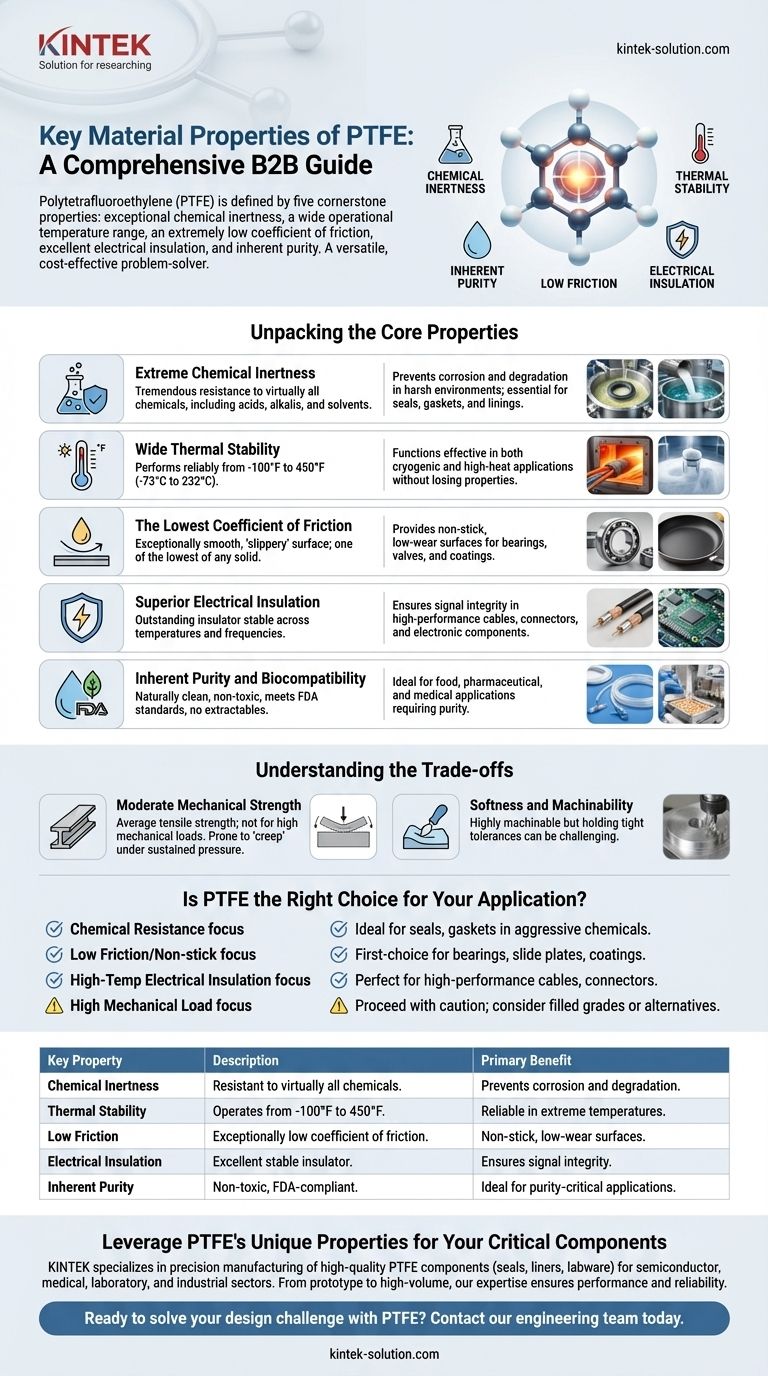

In material science, Polytetrafluoroethylene (PTFE) is defined by five cornerstone properties: exceptional chemical inertness, a wide operational temperature range, an extremely low coefficient of friction, excellent electrical insulation, and inherent purity. These characteristics make it a uniquely versatile and cost-effective problem-solver for demanding applications.

PTFE, commonly known by the brand name Teflon®, is the go-to material when you need a component to survive extreme chemical environments and high temperatures while providing a non-stick, low-friction surface. Its unique combination of properties makes it a problem-solver in industries ranging from chemical processing to food production.

Unpacking the Core Properties of PTFE

To truly understand PTFE's value, we must examine how each of its primary characteristics translates into real-world performance. These properties are not isolated; they work together to create a highly reliable material.

Extreme Chemical Inertness

PTFE has a tremendous resistance to virtually all chemicals, including aggressive acids, alkalis, and organic solvents.

This near-total chemical immunity means it will not corrode or degrade when exposed to harsh substances, making it essential for seals, gaskets, and linings in chemical processing equipment.

Wide Thermal Stability

The material performs reliably across a very broad temperature range, typically cited from -100°F to 450°F (-73°C to 232°C).

This allows PTFE to function effectively in both cryogenic applications and high-heat environments without losing its critical properties.

The Lowest Coefficient of Friction

PTFE has one of the lowest coefficients of friction of any known solid material. This gives it an exceptionally smooth, "slippery" surface.

This non-stick quality is fundamental to its use in low-friction bearings, valve components where easy operation is critical, and of course, non-stick coatings.

Superior Electrical Insulation

PTFE is an outstanding electrical insulator that maintains its properties across a wide spectrum of temperatures and frequencies.

This stability makes it a preferred material for high-performance wire and cable insulation, connectors, and other critical electronic components where signal integrity is paramount.

Inherent Purity and Biocompatibility

The material is naturally clean, non-toxic, and meets FDA standards for contact with food and pharmaceuticals.

Because it has virtually no extractables (meaning it doesn't leach chemicals), PTFE is a popular choice for tubing, containers, and processing equipment in the food, beverage, and medical industries.

Understanding the Trade-offs

No material is perfect. To make an informed decision, it's crucial to recognize PTFE's limitations, which primarily relate to its mechanical performance.

Moderate Mechanical Strength

While pliable, standard PTFE has only average tensile strength. It is not a structural plastic designed to bear high mechanical loads.

Under sustained pressure, especially at elevated temperatures, PTFE can be prone to "creep," or slow deformation over time.

Softness and Machinability

PTFE is a relatively soft material, which makes it highly machinable. However, this same softness can make holding very tight dimensional tolerances a challenge compared to harder engineering plastics.

Is PTFE the Right Choice for Your Application?

Your specific goal will determine if PTFE is the optimal material. Use these points as a guide.

- If your primary focus is chemical resistance: PTFE is nearly unmatched, making it ideal for seals, gaskets, and linings exposed to aggressive chemicals.

- If your primary focus is low friction or non-stick surfaces: PTFE's exceptionally low coefficient of friction makes it a first-choice material for bearings, slide plates, and coatings.

- If your primary focus is high-temperature electrical insulation: PTFE provides stable dielectric properties across a wide temperature and frequency range, perfect for high-performance cables and connectors.

- If your primary focus is high mechanical load: You should proceed with caution, as PTFE's average tensile strength may require using a filled grade (e.g., glass or carbon-filled) or an alternative material.

Ultimately, understanding these core properties allows you to leverage PTFE not just as a material, but as a specific solution to demanding engineering challenges.

Summary Table:

| Key Property | Description | Primary Benefit |

|---|---|---|

| Chemical Inertness | Resistant to virtually all chemicals, including strong acids and solvents. | Prevents corrosion and degradation in harsh environments. |

| Thermal Stability | Performs reliably from -100°F to 450°F (-73°C to 232°C). | Functions effectively in both cryogenic and high-heat applications. |

| Low Friction | One of the lowest coefficients of friction of any solid material. | Provides non-stick, low-wear surfaces for bearings and seals. |

| Electrical Insulation | Excellent insulator stable across temperatures and frequencies. | Ensures signal integrity in high-performance cables and connectors. |

| Inherent Purity | Non-toxic, FDA-compliant, with virtually no extractables. | Ideal for food, pharmaceutical, and medical applications requiring purity. |

Leverage PTFE's Unique Properties for Your Critical Components

PTFE's combination of properties makes it a problem-solving material for the most demanding environments. At KINTEK, we specialize in the precision manufacturing of high-quality PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors.

Whether you need a standard part or a custom-fabricated solution from prototype to high-volume production, our expertise ensures your components meet exact specifications for performance and reliability.

Ready to solve your design challenge with PTFE? Contact our engineering team today to discuss your application and receive a quote.

Visual Guide

Related Products

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- What is Teflon and what is its chemical name? Unpacking the Science of PTFE

- What environmental resistances does PTFE offer? Unmatched Durability for Harsh Conditions

- How was PTFE discovered and developed? From Lab Accident to Essential High-Performance Polymer

- What is PTFE and what class of plastics does it belong to? A Guide to High-Performance Fluoropolymers

- What is PTFE commonly known as and what type of material is it? A Guide to High-Performance PTFE Properties