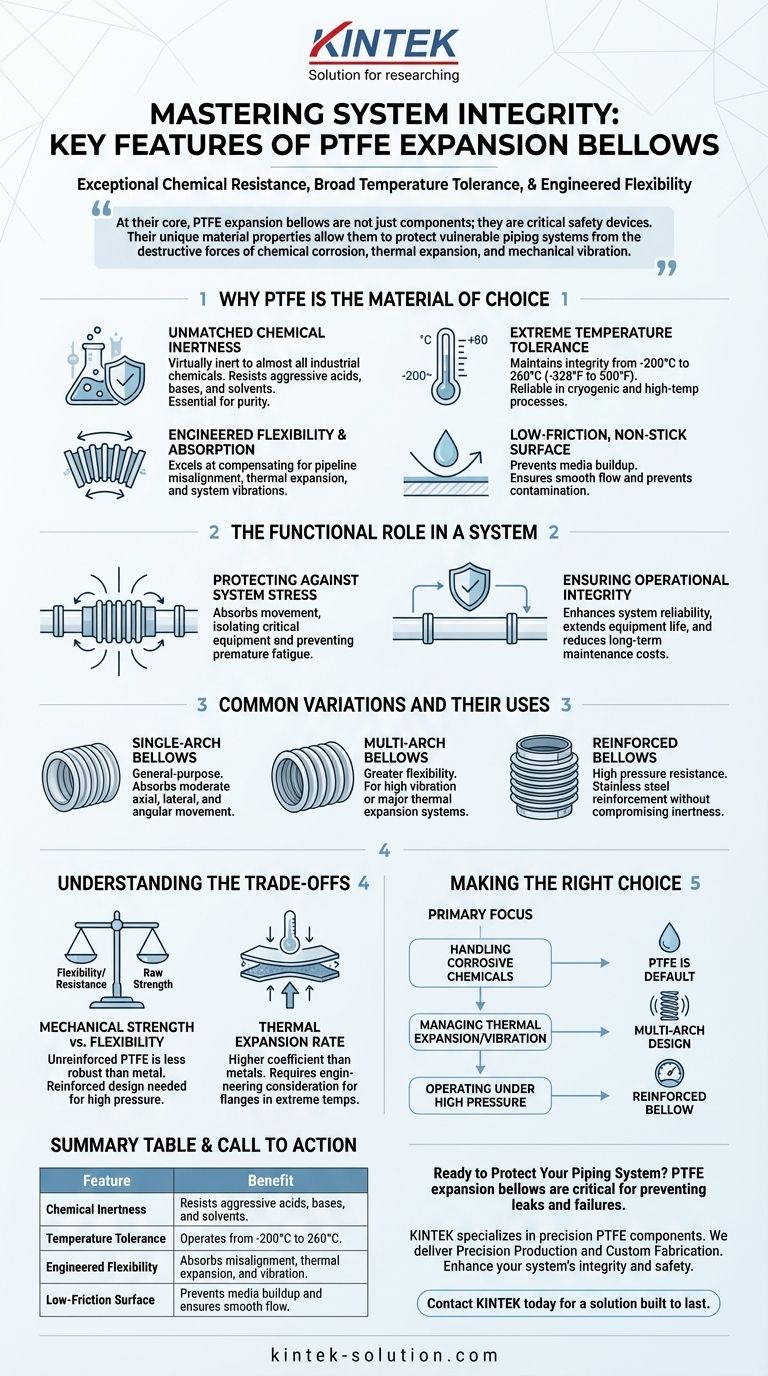

The key features of PTFE Expansion Bellows are their exceptional chemical resistance, broad temperature tolerance, and engineered flexibility. These properties allow them to safely absorb movement and stress in piping systems that handle aggressive substances or operate in extreme thermal conditions, preventing leaks and catastrophic failures.

At their core, PTFE expansion bellows are not just components; they are critical safety devices. Their unique material properties allow them to protect vulnerable piping systems from the destructive forces of chemical corrosion, thermal expansion, and mechanical vibration.

Why PTFE is the Material of Choice

The effectiveness of an expansion bellow is defined by its material. Polytetrafluoroethylene (PTFE) possesses a combination of properties that make it uniquely suited for the most demanding industrial environments.

Unmatched Chemical Inertness

PTFE is virtually inert to almost all industrial chemicals. It can withstand prolonged exposure to the most aggressive acids, bases, and solvents without degrading.

This makes it an essential material in chemical processing, pharmaceutical manufacturing, and any application where fluid purity and corrosion prevention are paramount.

Extreme Temperature Tolerance

These bellows maintain their structural integrity and performance across an exceptionally wide temperature range, typically from -200°C to 260°C (-328°F to 500°F).

This allows them to function reliably in systems involving cryogenic fluids or high-temperature processes without becoming brittle or losing their form.

Engineered Flexibility and Absorption

The primary mechanical function of a bellow is to absorb movement. PTFE bellows excel at compensating for pipeline misalignment, thermal expansion, and system vibrations.

By flexing, they absorb stresses that would otherwise be transferred to the rigid pipes and connections, which is a primary cause of cracks and joint failures.

Low-Friction, Non-Stick Surface

PTFE has one of the lowest coefficients of friction of any solid material. This non-stick characteristic prevents media from building up on the internal surfaces.

This is critical for ensuring smooth flow, preventing contamination in food and pharmaceutical applications, and reducing operational wear over time.

The Functional Role in a System

Understanding the material properties is only half the story. The true value of a PTFE expansion bellow lies in the problems it solves within a complex piping system.

Protecting Against System Stress

Piping systems are not static. They are constantly subjected to stress from pressure changes, fluid dynamics, and temperature fluctuations.

PTFE bellows act as the flexible, absorbent joint in the system. They isolate critical equipment from vibration and absorb expansion and contraction, preventing premature fatigue and failure of the entire pipeline.

Ensuring Operational Integrity

A pipeline failure results in costly downtime, potential safety hazards, and lost production.

By mitigating the root causes of mechanical stress and chemical corrosion, these bellows significantly enhance system reliability, extend the life of the equipment, and reduce long-term maintenance costs.

Common Variations and Their Uses

PTFE bellows are not a one-size-fits-all solution. Different designs are engineered to meet specific operational demands.

Single-Arch Bellows

This is the most common design, featuring a single convolution. It is ideal for general-purpose applications to absorb moderate levels of axial, lateral, and angular movement.

Multi-Arch Bellows

Featuring two or more convolutions, these bellows provide significantly greater flexibility and movement absorption capabilities. They are specified for systems with high vibration or major thermal expansion.

Reinforced Bellows

For applications involving higher pressures, PTFE bellows can be reinforced with external rings or layers, often made of stainless steel. This adds mechanical strength and pressure resistance without compromising the chemical inertness of the internal PTFE surface.

Understanding the Trade-offs

While highly effective, it is important to understand the practical limitations of PTFE to ensure proper application.

Mechanical Strength vs. Flexibility

Unreinforced PTFE is not as mechanically robust as metal. Its value lies in its chemical resistance and flexibility, not its raw tensile strength. In high-pressure environments, a reinforced design is non-negotiable.

Thermal Expansion Rate

PTFE has a higher coefficient of thermal expansion than metals. While the bellow is designed to absorb this, engineers must account for how the material itself will behave when designing flanges and connection points for extreme temperature applications.

Making the Right Choice for Your System

Selecting the correct bellow requires a clear understanding of your primary operational challenge.

- If your primary focus is handling corrosive chemicals: PTFE is the default choice due to its near-universal chemical inertness, ensuring system longevity and purity.

- If your primary focus is managing significant thermal expansion or vibration: A multi-arch design provides the superior flexibility needed to absorb extensive movement without fatiguing.

- If your primary focus is operating under high pressure: A reinforced bellow is essential to provide the necessary structural integrity to prevent a blowout.

Ultimately, choosing the right PTFE expansion bellow is a crucial step in engineering a safe, reliable, and durable industrial piping system.

Summary Table:

| Feature | Benefit |

|---|---|

| Chemical Inertness | Resists virtually all aggressive acids, bases, and solvents. |

| Temperature Tolerance | Operates from -200°C to 260°C (-328°F to 500°F). |

| Engineered Flexibility | Absorbs misalignment, thermal expansion, and vibration. |

| Low-Friction Surface | Prevents media buildup and ensures smooth flow. |

Ready to Protect Your Piping System?

PTFE expansion bellows are critical for preventing leaks and failures in demanding environments. At KINTEK, we specialize in manufacturing high-precision PTFE components, including custom bellows, for the semiconductor, medical, laboratory, and industrial sectors.

We deliver:

- Precision Production: Ensuring reliable performance and long service life.

- Custom Fabrication: From prototypes to high-volume orders, tailored to your specific pressure, temperature, and chemical requirements.

Enhance your system's integrity and safety. Contact KINTEK today to discuss your application and get a quote for a solution built to last.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts