The defining features of Polytetrafluoroethylene (PTFE) lip seals are their exceptionally low friction and their ability to operate reliably under extreme conditions where conventional elastomer seals would fail. They offer superior performance across a wide range of temperatures, pressures, and surface speeds, combined with near-universal chemical inertness, making them a specialized solution for demanding industrial, automotive, and aerospace applications.

PTFE lip seals are not a simple upgrade from standard rubber seals; they are an engineered solution for mission-critical applications where high temperatures, aggressive chemicals, high rotational speeds, or extreme pressures make traditional materials unsuitable.

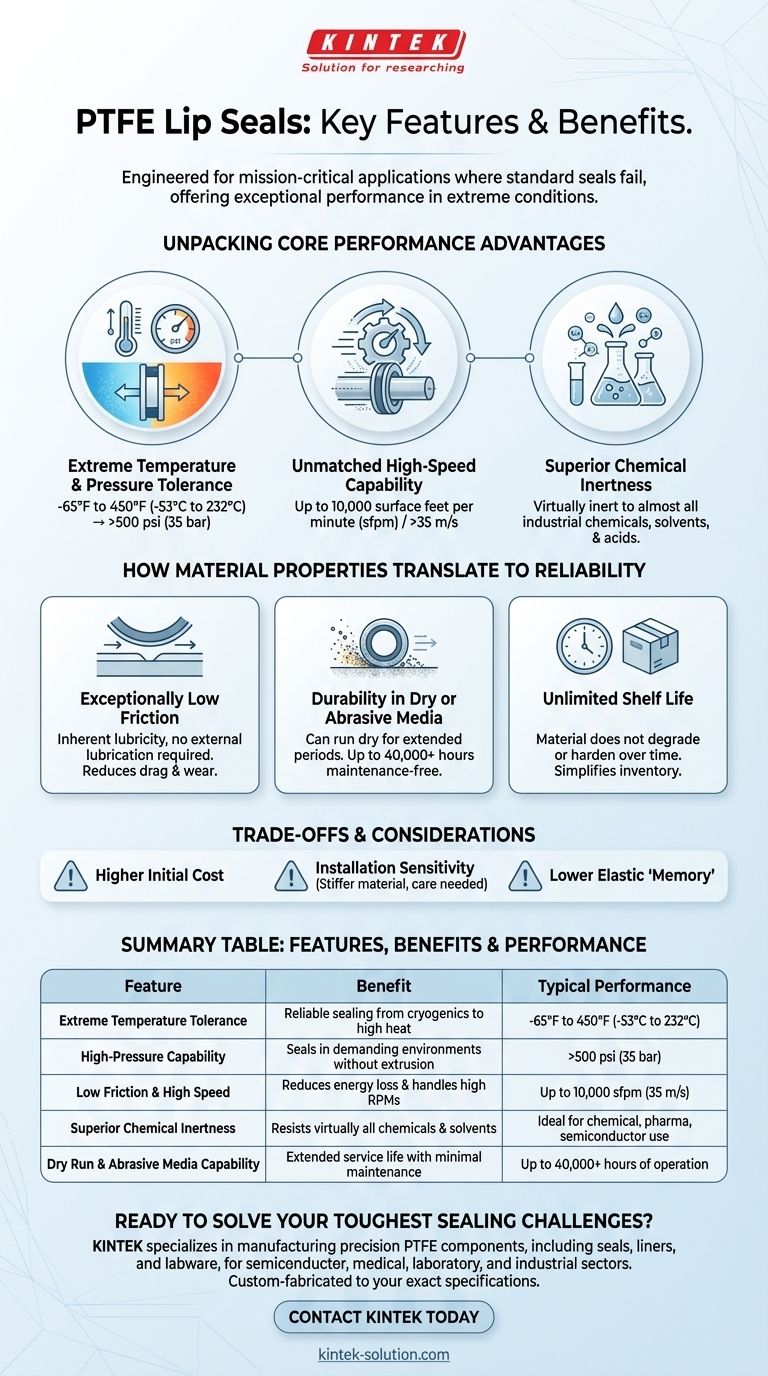

Unpacking the Core Performance Advantages

PTFE seals are specifically designed to solve engineering challenges that push beyond the limits of conventional materials. Their primary benefits stem from their ability to function in environments that would cause rapid degradation of other seal types.

Extreme Temperature and Pressure Tolerance

The operational range of PTFE is a key differentiator. It can reliably seal in temperatures from -65°F to 450°F (-53°C to 232°C).

This thermal stability allows them to be used in high-heat applications like engines and industrial gearboxes, as well as cryogenic systems, without becoming brittle or degrading.

Furthermore, they are engineered for high-pressure environments, capable of sealing in excess of 500 psi (35 bar), a level that would extrude or destroy most standard elastomeric seals.

Unmatched High-Speed Capability

Due to its low-friction nature, PTFE generates significantly less heat at the sealing point.

This allows PTFE lip seals to handle surface speeds of up to 10,000 surface feet per minute (sfpm), or over 35 m/s. In high-RPM rotating equipment, this prevents the premature wear and failure common with rubber seals.

Superior Chemical Inertness

PTFE is one of the most chemically resistant materials available. It is virtually inert to almost all industrial chemicals, solvents, and acids.

This property makes it the definitive choice for applications in the pharmaceutical, chemical processing, and semiconductor industries, where seals are exposed to aggressive media that would quickly dissolve other materials.

How Material Properties Translate to Reliability

The inherent molecular structure of PTFE provides functional benefits that directly impact efficiency, maintenance cycles, and overall system longevity.

Exceptionally Low Friction

PTFE has one of the lowest coefficients of friction of any solid material. This lubricity is inherent and does not require external lubrication.

This dramatically reduces rotational drag and energy loss in a system, improving overall efficiency. It also minimizes wear on the shaft, extending the life of both the seal and the equipment.

Durability in Dry or Abrasive Media

Unlike elastomer seals that require a consistent fluid film for lubrication, PTFE seals can run dry or in abrasive media for extended periods.

This unique capability extends their service life significantly, with some applications reporting over 40,000 hours of maintenance-free operation.

Unlimited Shelf Life

PTFE material does not degrade, harden, or change its properties over time when stored. This gives it an unlimited shelf life, simplifying inventory management and eliminating the risk of installing a degraded seal.

Understanding the Trade-offs and Considerations

While powerful, PTFE seals are a specialized component, and their selection requires an understanding of their specific characteristics.

Higher Initial Cost

PTFE is a premium material, and the manufacturing processes for creating precision seals are more complex than those for molded rubber. This results in a higher upfront cost compared to standard nitrile or Viton seals.

Installation Sensitivity

PTFE is a much stiffer material than rubber and has less elasticity. Care must be taken during installation to avoid nicking or deforming the seal lip, which can compromise its effectiveness. Some designs incorporate an elastomer outer diameter to simplify fitting.

Lower Elastic "Memory"

Unlike rubber, PTFE is not a true elastomer and does not rebound to its original shape as readily. In applications with significant shaft runout or surface imperfections, a PTFE seal may have more difficulty maintaining a consistent sealing interface compared to a more flexible elastomer.

Making the Right Choice for Your Application

Selecting the correct seal material is critical to ensuring system reliability and performance. The decision to use PTFE should be based on the specific demands of the operating environment.

- If your primary focus is extreme operating conditions (high heat, pressure, or speed): PTFE provides a level of durability and stability that standard elastomers cannot match.

- If your primary focus is chemical compatibility: PTFE's inertness makes it the only viable choice for sealing against aggressive solvents, acids, or process fluids.

- If your primary focus is reducing maintenance in a hard-to-service system: The long, predictable service life of PTFE seals can justify their initial cost by minimizing costly downtime.

- If your primary focus is a standard, low-cost application with moderate conditions: A conventional elastomer seal often provides a more cost-effective and perfectly adequate solution.

Ultimately, choosing a PTFE lip seal is an investment in reliability for applications where failure is not an option.

Summary Table:

| Feature | Benefit | Typical Performance |

|---|---|---|

| Extreme Temperature Tolerance | Reliable sealing from cryogenics to high heat | -65°F to 450°F (-53°C to 232°C) |

| High-Pressure Capability | Seals in demanding environments without extrusion | >500 psi (35 bar) |

| Low Friction & High Speed | Reduces energy loss and handles high RPMs | Up to 10,000 sfpm (35 m/s) |

| Superior Chemical Inertness | Resists virtually all industrial chemicals and solvents | Ideal for chemical, pharma, and semiconductor use |

| Dry Run & Abrasive Media Capability | Extended service life with minimal maintenance | Up to 40,000+ hours of operation |

Ready to Solve Your Toughest Sealing Challenges?

PTFE lip seals are engineered for mission-critical applications where standard seals fail. If your operations involve extreme temperatures, high pressures, aggressive chemicals, or require long-lasting, maintenance-free performance, KINTEK has the solution.

We specialize in manufacturing precision PTFE components—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures you get a component that is custom-fabricated to your exact specifications, from prototype to high-volume production.

Invest in reliability. Contact KINTEK today to discuss your specific requirements and let our experts provide a sealing solution that enhances your system's performance and longevity.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability