At its core, a heat-resistant Teflon sheet serves three critical functions in printing: it protects your garment from scorching, prevents ink and adhesives from contaminating your heat press, and ensures a clean, professional transfer. Its value comes from providing a durable, reusable, non-stick barrier that can withstand temperatures up to 500°F, making it indispensable for consistent, high-quality results.

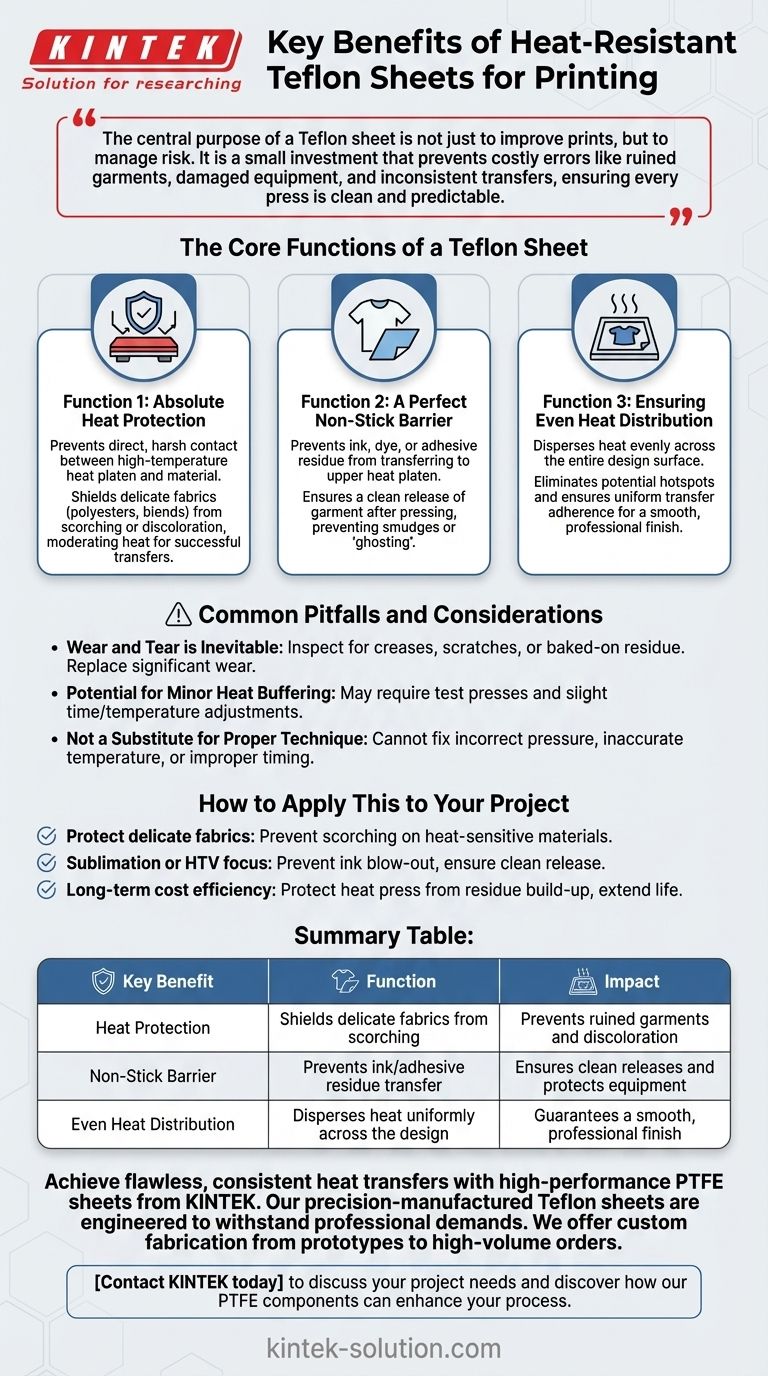

The central purpose of a Teflon sheet is not just to improve prints, but to manage risk. It is a small investment that prevents costly errors like ruined garments, damaged equipment, and inconsistent transfers, ensuring every press is clean and predictable.

The Core Functions of a Teflon Sheet

A Teflon sheet may seem simple, but it performs several distinct jobs simultaneously during the heat transfer process. Understanding these functions clarifies why it is considered essential equipment.

Function 1: Absolute Heat Protection

The most immediate benefit is preventing direct, harsh contact between the high-temperature heat platen and your material.

Delicate fabrics, especially polyesters and blends, are susceptible to scorching or discoloration under intense heat. The Teflon sheet acts as a protective shield, moderating the heat just enough to prevent damage while still allowing for a successful transfer.

Function 2: A Perfect Non-Stick Barrier

The non-stick property of Teflon is crucial for maintaining a clean work environment and a perfect final product.

This barrier prevents ink, dye, or adhesive residue from transferring onto the upper heat platen. A contaminated platen can ruin subsequent projects by pressing old residue onto a new garment.

It also ensures a clean release of the garment after pressing, preventing smudges or "ghosting" that can occur if the transfer paper sticks to the material.

Function 3: Ensuring Even Heat Distribution

While the heat platen itself is designed to heat evenly, minor fluctuations can exist. The Teflon sheet adds a final layer of consistency.

By sitting between the platen and the project, the sheet helps disperse the heat evenly across the entire surface of the design. This eliminates potential hotspots and ensures the transfer adheres uniformly for a smooth, professional finish.

Common Pitfalls and Considerations

While highly effective, a Teflon sheet is a tool that must be used and maintained correctly. Simply owning one does not guarantee perfect results.

Wear and Tear is Inevitable

Although durable and reusable, these sheets do not last forever. Over time, they can develop creases, scratches, or baked-on residue that can transfer an unwanted texture or stain to your print.

Always inspect your sheet before use and replace it if it shows signs of significant wear.

Potential for Minor Heat Buffering

Adding any layer between the heat source and the garment can slightly alter the required temperature or time. The sheet can absorb a small amount of energy, acting as a minor heat buffer.

You may need to perform test presses and slightly increase your time or temperature settings to compensate for this effect and achieve the perfect transfer.

Not a Substitute for Proper Technique

A Teflon sheet is a safeguard, not a solution for poor technique. It cannot fix problems caused by incorrect pressure, inaccurate temperature, or improper timing.

It is a component of a successful process, working alongside properly calibrated equipment and correct operational procedures to deliver professional-grade results.

How to Apply This to Your Project

Using a Teflon sheet is a simple step that protects your investment in materials and equipment, but its primary value depends on your specific goal.

- If your primary focus is protecting delicate fabrics: Use the sheet to prevent scorching and yellowing on polyesters, nylons, and other heat-sensitive materials.

- If your primary focus is sublimation or HTV: Rely on its non-stick properties to prevent ink blow-out from staining your platen and to ensure a clean release every time.

- If your primary focus is long-term cost efficiency: View the sheet as essential maintenance hardware that protects your expensive heat press from residue build-up, extending its life and performance.

Ultimately, a heat-resistant Teflon sheet is a fundamental component for achieving consistent, professional results in any heat transfer application.

Summary Table:

| Key Benefit | Function | Impact |

|---|---|---|

| Heat Protection | Shields delicate fabrics from scorching | Prevents ruined garments and discoloration |

| Non-Stick Barrier | Prevents ink/adhesive residue transfer | Ensures clean releases and protects equipment |

| Even Heat Distribution | Disperses heat uniformly across the design | Guarantees a smooth, professional finish |

Achieve flawless, consistent heat transfers with high-performance PTFE sheets from KINTEK.

Our precision-manufactured Teflon sheets are engineered to withstand the demands of professional printing, safeguarding your materials and equipment. Whether you're in the garment, industrial, or specialty printing industry, KINTEK provides the durable, reusable barriers you need for perfect results every time.

We offer custom fabrication from prototypes to high-volume orders to meet your exact specifications.

Contact KINTEK today to discuss your project needs and discover how our PTFE components can enhance your process.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- When and by whom was PTFE discovered? A Tale of Accidental Innovation

- How does PTFE compare to other low-friction plastics like UHMW-PE and Nylon? A Guide to Material Selection

- Why is dimensional stability a concern when machining PTFE? Ensure Accurate, Stable PTFE Components

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- What are some important physical property values for PTFE? Master Its Extreme Performance for Demanding Applications