Successfully machining Polytetrafluoroethylene (PTFE) requires a specific approach that differs significantly from working with metals or harder plastics. The key aspects involve managing its unique material properties through specialized tool selection, optimized machine parameters, careful workholding, and post-machining considerations to control for its inherent instability.

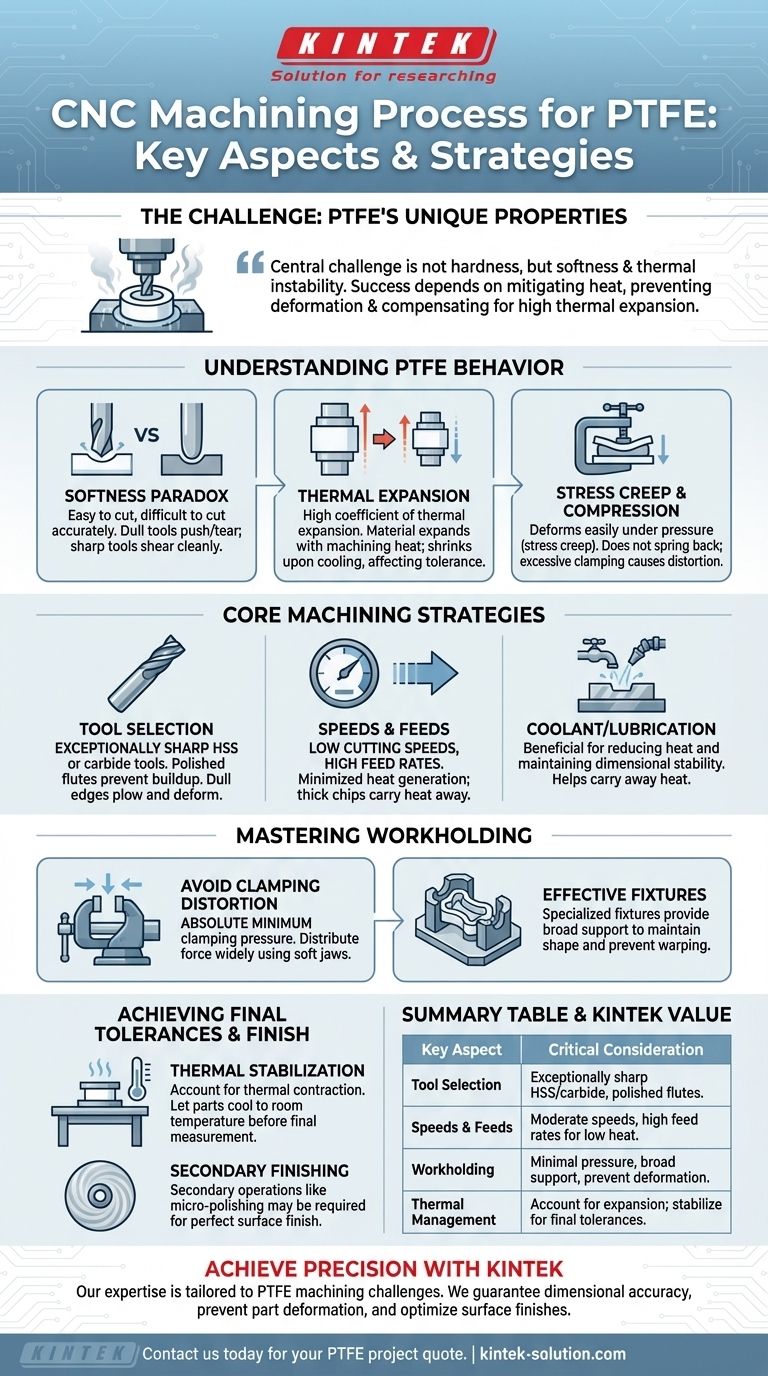

The central challenge in machining PTFE is not its hardness, but its softness and thermal instability. Success depends entirely on mitigating heat generation, preventing deformation from clamping forces, and compensating for its high thermal expansion to achieve dimensional accuracy.

Understanding PTFE's Unique Machining Behavior

To machine PTFE effectively, you must first understand its core properties. Its characteristics present a paradox: it is easy to cut, but difficult to cut accurately.

The Paradox of Softness

PTFE's softness and very low coefficient of friction mean that cutting tools move through it with little resistance.

However, this same softness means the material can easily be pushed or torn by a dull tool rather than being sheared cleanly, leading to a poor surface finish.

The Challenge of Thermal Expansion

PTFE has a very high coefficient of thermal expansion. Even the minimal heat generated during machining will cause the material to expand significantly.

As the part cools, it will shrink, meaning a part that was perfectly to-spec on the machine may be undersized after it has stabilized to room temperature.

The Problem of Stress Creep and Compression

This material deforms easily under pressure and does not spring back to its original shape. This is known as stress creep.

Excessive clamping pressure in a vise or fixture will compress the material, leading to inaccurate dimensions and potentially warping the part once it is released.

Core Machining Strategies and Parameters

A successful PTFE machining process is built on a foundation of controlling heat and physical forces.

Tool Selection: Sharpness is Non-Negotiable

Your cutting tools must be exceptionally sharp, with polished flutes to prevent material buildup. High-Speed Steel (HSS) or carbide tools are both effective.

A dull edge will plow through the material instead of cutting it, generating excess heat and deforming the part.

Speeds and Feeds: A Low-Heat Approach

Use moderate to low cutting speeds to minimize heat generation. High RPMs will quickly cause the material to heat up, expand, and fail to hold tolerance.

Employ a high feed rate and a relatively small depth of cut. This creates a thicker chip that carries heat away from the workpiece and ensures the tool is continuously cutting fresh material.

The Role of Coolant and Lubrication

While not always required, using a lubricant or coolant can be beneficial.

Its primary purpose is to reduce and carry away heat, helping to maintain the dimensional stability of the workpiece during the cutting operation.

Mastering Workholding and Fixturing

How you hold the PTFE stock is one of the most critical factors for success. Improper fixturing is a primary cause of failed parts.

Avoiding Clamping Distortion

Use the absolute minimum clamping pressure required to hold the part securely. Overtightening will inevitably compress and distort the workpiece.

Distribute the clamping force over a wide surface area using soft jaws or custom fixtures to avoid creating pressure points that can permanently deform the material.

Designing Effective Fixtures

For complex parts, consider specialized fixtures designed for soft materials. These fixtures should provide broad support across the entire part to maintain its shape and prevent warping during machining.

Achieving Final Tolerances and Finish

The final steps are crucial for ensuring the part meets its required specifications after it leaves the machine.

Accounting for Post-Machining Changes

To achieve tight tolerances, you must account for thermal contraction. It is often necessary to let the part cool and stabilize at room temperature before taking a final measurement or performing a finishing pass.

Secondary Finishing Operations

PTFE's softness can make achieving a perfectly smooth surface directly from the machine challenging. Secondary processes like micro-polishing may be required to meet specific surface finish requirements.

How to Apply This to Your Project

Your specific machining strategy should be guided by your project's most critical outcome.

- If your primary focus is achieving tight dimensional tolerances: Your strategy must revolve around aggressive heat management and allowing the part to stabilize before final measurement.

- If your primary focus is excellent surface finish: Use exceptionally sharp, polished tools with a high positive rake angle and plan for potential secondary finishing operations.

- If your primary focus is avoiding part deformation: Design fixtures that provide broad, gentle support and train operators to use the absolute minimum clamping pressure necessary.

By respecting PTFE's unique properties instead of fighting them, you can consistently achieve precise and reliable results.

Summary Table:

| Key Aspect | Critical Consideration |

|---|---|

| Tool Selection | Exceptionally sharp HSS or carbide tools with polished flutes. |

| Speeds & Feeds | Moderate speeds, high feed rates to minimize heat generation. |

| Workholding | Minimal clamping pressure with broad support to prevent deformation. |

| Thermal Management | Account for high thermal expansion; allow parts to stabilize for final tolerances. |

Achieve precision-machined PTFE components with KINTEK.

Our expertise is specifically tailored to the unique challenges of machining PTFE, Teflon®, and other high-performance polymers. We understand that success hinges on managing softness and thermal expansion to meet your exact specifications for seals, liners, labware, and custom parts.

We deliver value by:

- Guaranteeing Dimensional Accuracy: Our specialized processes account for PTFE's properties to ensure your parts meet tight tolerances.

- Preventing Part Deformation: We use custom fixtures and precise workholding techniques to avoid stress creep and warping.

- Optimizing Surface Finishes: From initial machining to secondary polishing, we achieve the surface quality your application demands.

Whether you need prototypes or high-volume production for the semiconductor, medical, or laboratory industries, trust KINTEK for precision and reliability.

Contact us today to discuss your PTFE machining project and get a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments