The key advantages of using PTFE packing stem from its unique molecular structure, granting it exceptional chemical resistance, an extremely low coefficient of friction, and broad temperature stability. These core attributes make it a highly reliable and versatile sealing solution for a wide range of demanding industrial applications, from chemical processing to food production.

While often chosen for its near-universal chemical inertness, the true value of PTFE packing lies in its combination of properties. This synergy reduces equipment wear, lowers energy consumption, and ensures product purity in sensitive environments, making it one of the most dependable sealing materials available.

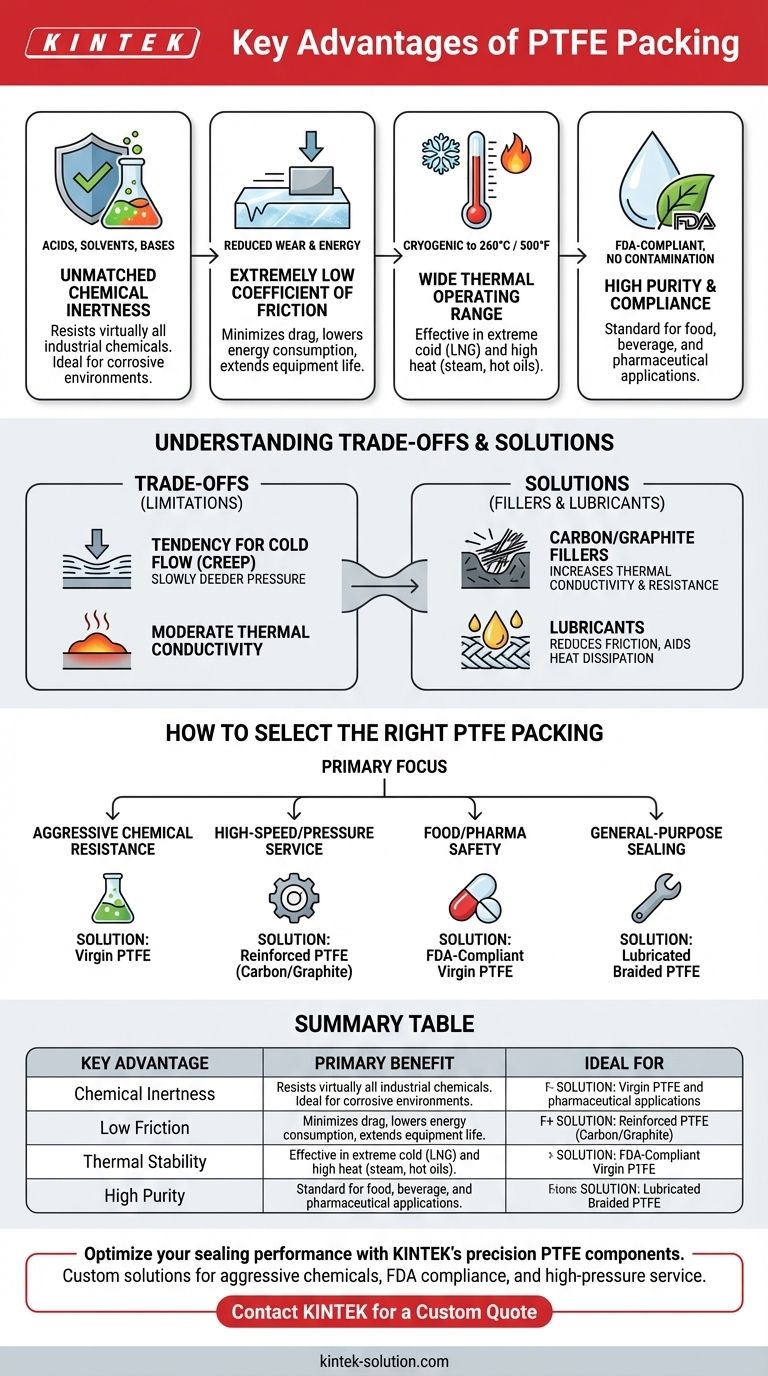

Deconstructing the Core Advantages

To understand why PTFE packing is so widely specified, it's essential to analyze its primary characteristics and their direct impact on operational performance.

Unmatched Chemical Inertness

PTFE is one of the most chemically resistant materials known. It is virtually inert and does not react with the vast majority of industrial chemicals, including aggressive acids, solvents, and bases.

This makes it an ideal choice for sealing pumps, valves, and flanges in environments handling corrosive media like concentrated sulfuric or nitric acid, where other materials would quickly degrade.

Extremely Low Coefficient of Friction

PTFE has one of the lowest friction coefficients of any solid material, often compared to wet ice on wet ice. This "non-stick" quality has significant mechanical benefits.

It results in reduced drag and wear on rotating shafts and valve stems, which directly translates to lower energy consumption and extended equipment life. This property also minimizes heat generation during operation, a critical factor in high-speed applications.

Wide Thermal Operating Range

PTFE packing maintains its integrity and performance across an exceptionally broad temperature spectrum. It remains effective from cryogenic temperatures up to approximately 260°C (500°F).

This thermal stability allows it to be used in processes involving extreme cold, such as LNG handling, as well as in applications with high-temperature fluids like steam or hot oils, without becoming brittle or degrading.

High Purity and Compliance

Virgin PTFE is inherently pure and does not leach or contaminate the media it contacts. It does not bleed color or flavor, a critical attribute for specific industries.

Because of this purity, many grades of PTFE packing are FDA-compliant, making them the standard choice for applications in food processing, beverage production, and pharmaceutical manufacturing where product integrity is non-negotiable.

Understanding the Trade-offs

No material is perfect for every situation. Objectively assessing PTFE's limitations is crucial for proper application and avoiding premature failure.

Tendency for Cold Flow

Pure, unfilled PTFE can exhibit "creep" or cold flow, meaning it can slowly deform over time when subjected to constant pressure and temperature.

In high-pressure sealing applications, this can lead to a loss of sealing force. This limitation is often overcome by incorporating filler materials.

Moderate Thermal Conductivity

While stable at high temperatures, PTFE itself is not a great conductor of heat. In very high-speed rotating equipment, the heat generated by friction at the sealing surface may not dissipate quickly enough.

This can cause the packing to expand, increasing friction and potentially leading to thermal failure. Again, this is often addressed with specific additives.

The Role of Fillers and Lubricants

To counteract these limitations, PTFE is often blended with other materials. Carbon or graphite fillers are added to increase thermal conductivity and improve resistance to creep. Lubricants are also impregnated into the braided packing to reduce friction further and aid in heat dissipation during break-in.

How to Select the Right PTFE Packing

Matching the packing material to the operational demands of the equipment is the final and most critical step. Your decision should be guided by your primary operational goal.

- If your primary focus is aggressive chemical resistance: A pure, virgin PTFE packing provides the most comprehensive inertness for handling harsh acids and solvents.

- If your primary focus is high-speed or high-pressure service: Select a PTFE packing reinforced with carbon or graphite fibers to manage heat and resist deformation.

- If your primary focus is food or pharmaceutical safety: You must specify an FDA-compliant, virgin PTFE packing to ensure absolute purity and prevent contamination.

- If your primary focus is general-purpose sealing with a long service life: A high-quality, lubricated, and braided PTFE packing offers an excellent balance of low friction, durability, and cost-effectiveness.

Choosing the correct PTFE variant transforms a good sealing solution into the optimal one for your specific operational needs.

Summary Table:

| Key Advantage | Primary Benefit | Ideal For |

|---|---|---|

| Chemical Inertness | Resists acids, solvents, and bases | Chemical processing, aggressive media |

| Low Friction | Reduces wear and energy consumption | High-speed pumps, valves |

| Thermal Stability | Performs from cryogenic to 260°C (500°F) | High-temperature fluids, LNG handling |

| High Purity | FDA-compliant, prevents contamination | Food, pharmaceutical, beverage production |

Optimize your sealing performance with KINTEK's precision PTFE components.

Our expertise in custom fabricating PTFE seals, packings, liners, and labware ensures you get a solution tailored to your specific operational demands—whether you're handling aggressive chemicals, require FDA compliance, or need to manage high-pressure, high-speed service.

We partner with semiconductor, medical, laboratory, and industrial clients to deliver reliability and purity from prototype to high-volume production.

Contact KINTEK today to discuss your application and receive a custom solution quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- Why is PTFE considered a significant discovery? A Material That Revolutionized Industry

- What is the temperature range that PTFE can withstand? From -200°C to +260°C for Demanding Applications

- What are some applications of CNC machined PTFE parts? Critical Components for Medical, Electrical & Food Industries

- How does PTFE compare to other low-friction plastics like UHMW-PE and Nylon? A Guide to Material Selection

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications