The key advantages of PTFE bushes are their self-lubricating nature and extreme environmental resistance. Unlike traditional metal components, they possess an exceptionally low coefficient of friction, high chemical inertness, and a wide operating temperature range. These inherent properties allow them to operate without external lubrication, drastically reducing maintenance while ensuring reliability in conditions that would cause metal bearings to corrode, seize, or fail.

PTFE bushes are not just a component replacement; they are a strategic choice to eliminate maintenance, improve system efficiency, and ensure operational reliability in environments where traditional lubricated metal bearings are impractical or would inevitably fail.

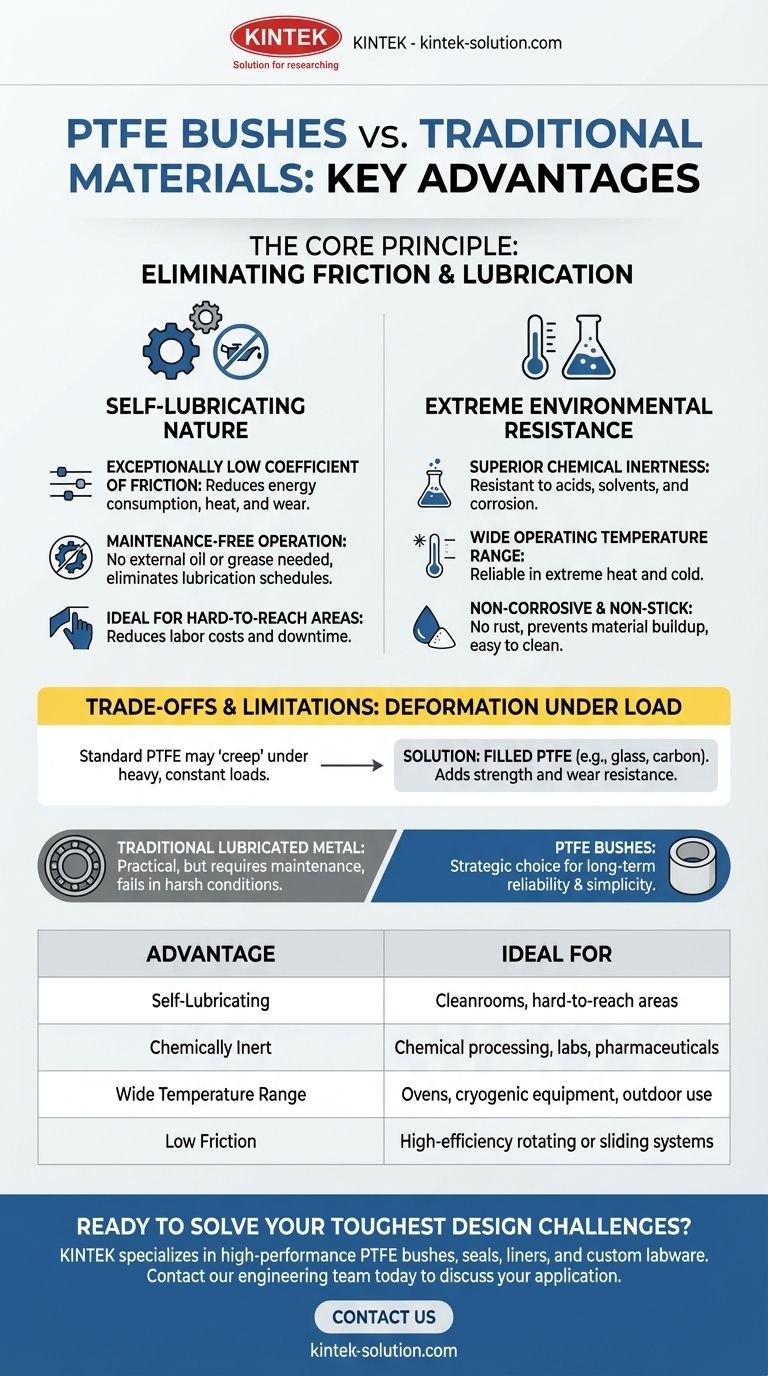

The Core Principle: Eliminating Friction and Lubrication

The most significant advantage of PTFE is its ability to fundamentally change how a mechanical system is designed and maintained. It moves beyond the traditional model of requiring constant lubrication.

Exceptionally Low Coefficient of Friction

PTFE has one of the lowest coefficients of friction of any solid material. This means that parts can slide or rotate against it with minimal resistance.

This property directly translates to lower energy consumption, reduced heat generation, and less wear on mating components over the lifespan of the equipment.

The Power of Self-Lubrication

PTFE bushes are inherently self-lubricating. They do not require external oil or grease to function effectively.

This eliminates a major point of failure found in traditional systems, where missed lubrication schedules can lead to catastrophic bearing seizure and equipment damage.

Maintenance-Free Operation

The combination of low friction and self-lubrication results in a component that is virtually maintenance-free.

This is ideal for applications where access is difficult, in clean environments like food processing where contamination is a concern, or in any system where reducing labor costs and downtime is a priority.

Unmatched Resilience in Hostile Environments

Many applications involve conditions that are too aggressive for standard metals. PTFE excels in these scenarios, providing a durable and reliable solution.

Superior Chemical Inertness

PTFE is resistant to nearly all industrial chemicals, acids, and solvents.

This makes it the default choice for pumps, valves, and rotating equipment used in chemical processing, pharmaceuticals, and laboratory settings where corrosion would quickly destroy metal bearings.

High-Temperature Stability

These bushes can operate reliably across a very wide range of temperatures, withstanding extreme heat and cold where traditional lubricants would either burn off or become too viscous.

This ensures consistent performance in applications from cryogenic equipment to industrial ovens.

Non-Corrosive and Non-Stick Properties

Unlike bronze or steel, PTFE does not rust or corrode when exposed to moisture or salt. Its surface is also non-stick, which prevents material buildup and simplifies cleaning.

This makes it highly suitable for marine applications, outdoor equipment, and food or medical machinery.

Understanding the Trade-offs and Limitations

While powerful, PTFE is not the solution for every problem. Acknowledging its limitations is key to using it effectively.

Deformation Under Load

Standard, unfilled PTFE can be prone to "creep" or deformation when subjected to heavy, constant loads. It is softer than metal and can be slowly compressed over time.

This makes it less suitable for high-load, static applications compared to a solid metal bearing.

The Cost and Material Variants

High-performance PTFE, especially modified grades, can have a higher initial material cost than a simple metal bushing.

To overcome the issue of creep, filled PTFE materials are often used. By adding fillers like glass, carbon, or graphite, manufacturers can significantly improve the material's strength, wear resistance, and resistance to deformation under load, making it a more robust alternative.

Making the Right Choice for Your Application

Selecting the correct material depends entirely on the primary challenge you need to solve.

- If your primary focus is reducing maintenance and operational costs: PTFE's self-lubricating nature eliminates the need for greasing schedules, reduces labor, and minimizes downtime.

- If your application involves harsh chemicals or extreme temperatures: PTFE's inherent chemical and thermal resistance offers unparalleled reliability where metals would quickly corrode or fail.

- If you are designing for high efficiency and low friction: The exceptionally low coefficient of friction minimizes energy loss and wear in sliding or rotating systems.

- If your design involves heavy static loads or requires high dimensional stability: Consider a filled PTFE variant to gain the benefits of the material without the risk of creep and deformation.

Ultimately, choosing PTFE is an investment in long-term reliability and operational simplicity for your most demanding applications.

Summary Table:

| Advantage | Key Benefit | Ideal For |

|---|---|---|

| Self-Lubricating | Eliminates external lubrication, reduces maintenance | Cleanrooms, hard-to-reach areas |

| Chemically Inert | Resists acids, solvents, and corrosion | Chemical processing, labs, pharmaceuticals |

| Wide Temperature Range | Performs in extreme heat and cold | Ovens, cryogenic equipment, outdoor use |

| Low Friction | Reduces energy consumption and wear | High-efficiency rotating or sliding systems |

Ready to solve your toughest design challenges with precision PTFE components?

KINTEK specializes in manufacturing high-performance PTFE bushes, seals, liners, and custom labware for the semiconductor, medical, laboratory, and industrial sectors. Whether you need a prototype or a high-volume order, our expertise in custom fabrication ensures you get a component designed for reliability and longevity.

Contact our engineering team today to discuss how our PTFE solutions can enhance your application's performance and reduce your total cost of ownership.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What are the base characteristics of PTFE? Unlocking Extreme Performance in Friction, Temperature, and Chemical Resistance

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What is PTFE commonly known as and what are its unique properties? Unlock Unmatched Chemical & Thermal Resistance

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance