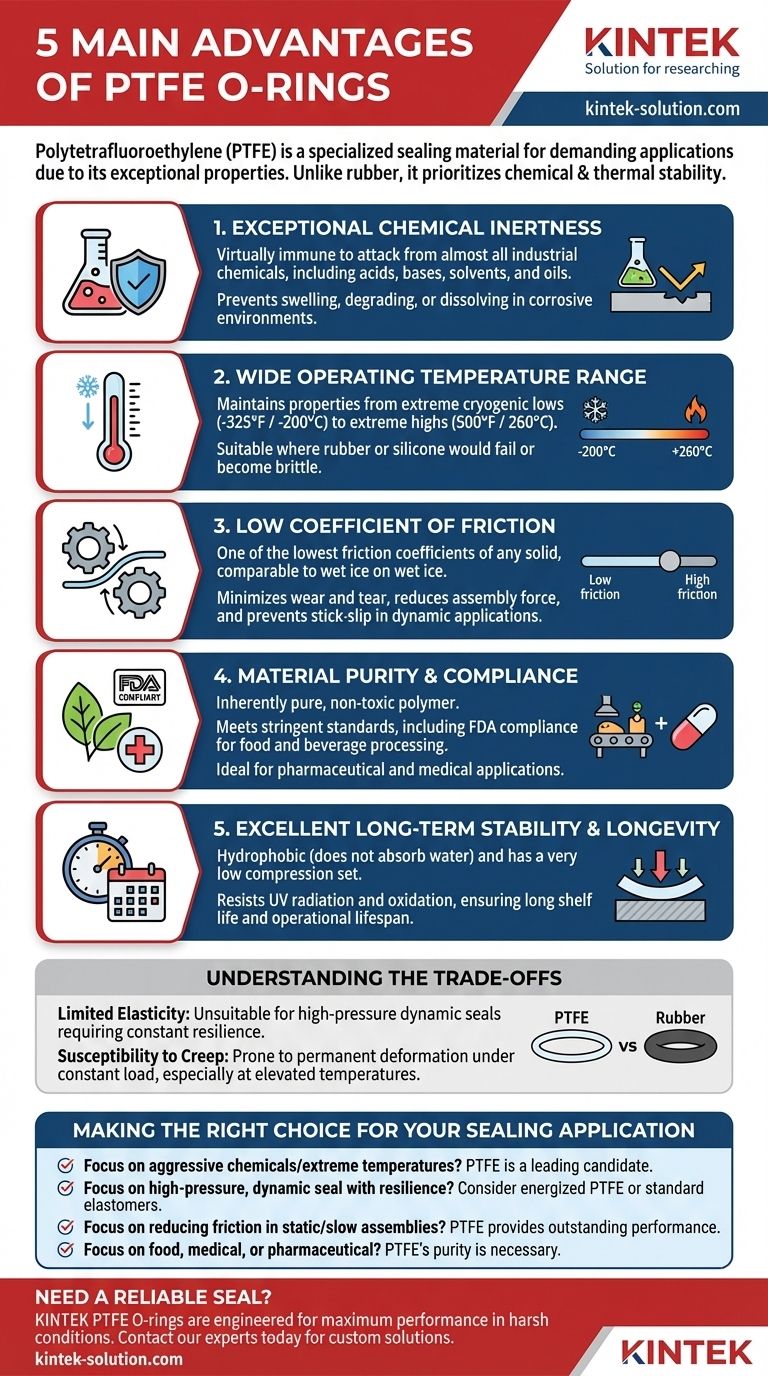

In short, the five main advantages of PTFE O-rings are their exceptional chemical inertness, wide operating temperature range, extremely low friction, inherent material purity, and excellent long-term stability. These properties make Polytetrafluoroethylene (PTFE) a specialized sealing material for demanding applications where common elastomers would quickly fail.

The core reason to choose a PTFE O-ring is for its unrivaled stability in harsh environments. Unlike rubber-based seals that rely on flexibility, PTFE's value comes from its sheer resistance to chemical attack, extreme temperatures, and friction.

The Core Advantages of PTFE Explained

To understand if PTFE is the right material for your needs, it's essential to look beyond the list and see how these properties translate into real-world performance.

1. Exceptional Chemical Inertness

PTFE is one of the most chemically resistant materials known. It is virtually immune to attack from almost all industrial chemicals, including aggressive acids, bases, solvents, and oils.

This universal resistance prevents the O-ring from swelling, degrading, or dissolving, ensuring the integrity of the seal in corrosive environments.

2. Wide Operating Temperature Range

PTFE maintains its properties across an exceptionally broad temperature spectrum, typically from cryogenic lows of -325°F (-200°C) up to highs of 500°F (260°C).

This makes it suitable for applications involving extreme heat or cold where traditional rubber or silicone O-rings would become brittle or lose their structural integrity.

3. Low Coefficient of Friction

PTFE has one of the lowest coefficients of friction of any solid material, often compared to wet ice on wet ice. This "slipperiness" is a major advantage in dynamic applications.

This property minimizes wear and tear on both the O-ring and the moving parts it seals against. It also reduces the force needed for assembly and prevents stick-slip issues during operation.

4. Material Purity and Compliance

PTFE is an inherently pure and non-toxic polymer. Because of this, it can meet stringent industry standards, including FDA compliance for food and beverage processing.

Its non-contaminating nature makes it a default choice for sensitive applications in the pharmaceutical, medical, and food production industries.

5. Excellent Material Stability and Longevity

PTFE is hydrophobic, meaning it does not absorb water or swell. It also boasts a very low compression set, meaning it resists permanent deformation after being compressed.

Combined with its resistance to UV radiation and oxidation, these characteristics give PTFE O-rings a very long shelf life and operational lifespan, reducing maintenance and replacement costs.

Understanding the Trade-offs of Pure PTFE

No material is perfect. Acknowledging PTFE's limitations is critical for making an informed engineering decision. Its greatest strengths are directly linked to its primary weaknesses.

Limited Elasticity and Memory

The most significant trade-off is PTFE's rigidity. Unlike elastomers like rubber, it is not truly elastic and does not spring back to its original shape effectively after being compressed.

This makes pure PTFE O-rings unsuitable for high-pressure dynamic sealing applications that require a constant, resilient sealing force. They are often used in static or slow-moving applications.

Susceptibility to Creep

Under a constant load, especially at elevated temperatures, PTFE can be prone to "creep" or cold flow. This is a slow, permanent deformation of the material.

Engineers must account for this behavior in the design of the seal gland to ensure long-term sealing performance is maintained.

Solid PTFE vs. PTFE-Coated O-Rings

It's important to distinguish between solid PTFE O-rings and PTFE-coated O-rings. A coated O-ring consists of a rubber core (providing elasticity) with a thin PTFE layer on the surface (providing low friction).

While coatings are excellent for reducing installation friction, the coating is thin, can be porous, and will eventually wear away in dynamic applications, exposing the core elastomer.

Making the Right Choice for Your Sealing Application

Selecting the correct O-ring material requires matching its properties to the demands of the operating environment.

- If your primary focus is aggressive chemicals or extreme temperatures: PTFE's inertness and thermal stability make it a leading candidate where other materials are not an option.

- If your primary focus is a high-pressure, dynamic seal requiring resilience: A pure PTFE O-ring is likely unsuitable; consider an energized PTFE seal or a standard elastomer.

- If your primary focus is reducing friction in a static or slow-moving assembly: PTFE's low coefficient of friction provides outstanding performance and prevents damage to components.

- If your primary focus is food, medical, or pharmaceutical applications: PTFE's inherent purity and compliance make it a safe, reliable, and often necessary choice.

Ultimately, choosing PTFE is a decision to prioritize chemical and thermal stability over the elasticity typical of conventional O-rings.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Exceptional Chemical Inertness | Resists virtually all industrial chemicals, acids, and solvents. |

| Wide Operating Temperature Range | Performs from -200°C to +260°C (-325°F to 500°F). |

| Low Coefficient of Friction | Minimizes wear and reduces assembly force in dynamic applications. |

| Material Purity and Compliance | Inherently pure, non-toxic, and meets FDA standards. |

| Excellent Long-Term Stability | Resists compression set, water absorption, and degradation. |

Need a reliable seal for a demanding application?

PTFE O-rings from KINTEK are engineered for maximum performance in the harshest conditions. Whether you're in the semiconductor, medical, laboratory, or industrial sector, our precision-manufactured PTFE components—from custom prototypes to high-volume orders—deliver the chemical resistance, thermal stability, and purity your application requires.

Contact our experts today to discuss your specific needs and discover how our PTFE sealing solutions can enhance your project's reliability and longevity.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability