Absolutely, Teflon sheets are engineered for exceptional durability and reusability. Their value comes from a unique combination of heat resistance, abrasion resistance, and a non-stick surface. This allows them to be cleaned and used repeatedly in demanding applications without degrading, protecting both your materials and your equipment over many cycles.

The core benefit of a Teflon sheet is not just its performance in a single use, but its ability to deliver consistent, clean, and protected results over a long lifespan. This durability translates directly into lower long-term costs, less waste, and higher quality outcomes.

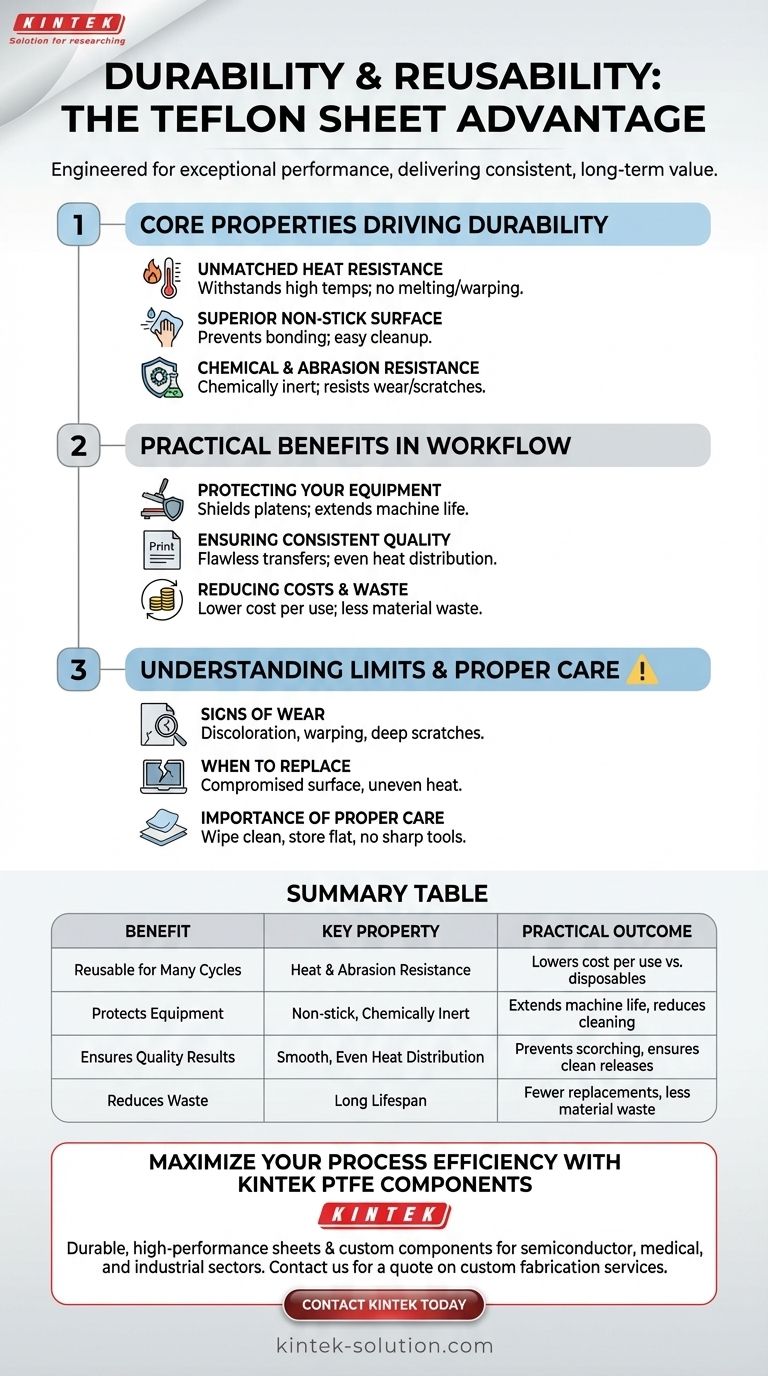

The Core Properties Driving Durability

The longevity of a Teflon sheet is not an accident; it's a direct result of the core properties of its PTFE (Polytetrafluoroethylene) coating. Understanding these properties helps clarify why it's such a reliable tool.

Unmatched Heat Resistance

Teflon's primary advantage is its ability to withstand high temperatures without melting, warping, or degrading. This is essential for applications like heat pressing and sublimation, where consistent heat is critical for a successful transfer.

Superior Non-Stick Surface

The famous non-stick quality of Teflon prevents inks, adhesives, and other materials from permanently bonding to the sheet. This ensures a clean release from your project and makes cleanup incredibly simple, often requiring just a quick wipe with a cloth.

Chemical and Abrasion Resistance

PTFE is chemically inert, meaning it doesn't react with most chemicals. Combined with its natural resistance to scratching and wear, this property makes it a durable choice for a wide range of industrial processes beyond just heat applications.

How Durability Translates to Practical Benefits

The physical properties of Teflon sheets create tangible advantages in any workflow, from crafting to industrial manufacturing. These benefits center on protection, quality, and cost-efficiency.

Protecting Your Equipment

The sheet acts as a crucial barrier between your project and your equipment. For heat presses, it shields the heat platen from ink stains, adhesive residue, and scorch marks, dramatically reducing cleaning time and extending the life of the machine.

Ensuring Consistent Quality

By providing a smooth, non-stick barrier, a Teflon sheet prevents scorching on sensitive fabrics and ensures even heat distribution across the material. This eliminates blotchy transfers and smudges, leading to flawless, professional-grade results every time.

Reducing Costs and Waste

Because a single sheet can be reused many times, it significantly lowers the cost per application compared to disposable alternatives like parchment paper. This reduces material waste and the need for frequent reordering.

Understanding the Limits and Proper Care

While highly durable, Teflon sheets are not indestructible. Recognizing the signs of wear is key to maintaining quality and knowing when a replacement is necessary.

Signs of Wear to Watch For

You must inspect your sheet regularly. Look for significant discoloration, warping that prevents it from lying flat, or any deep scratches or peeling that compromise the non-stick surface.

When to Replace the Sheet

Once you notice these signs of wear, it's time to replace the sheet. A worn-out sheet can transfer uneven heat or leave residue on your project, defeating its purpose and potentially ruining your work.

The Importance of Proper Care

To maximize its lifespan, always wipe the sheet clean with a damp cloth after it has cooled. Avoid using sharp tools or abrasive cleaners on its surface, and store it flat to prevent creasing and warping.

Making the Right Choice for Your Application

To get the most value from your Teflon sheet, your maintenance and replacement schedule should align with your specific use case.

- If your primary focus is high-volume heat pressing: Regularly inspect for any residue or discoloration and replace the sheet at the first sign of warping to guarantee perfect print quality.

- If your primary focus is general crafting or occasional use: A simple wipe-down after use and proper flat storage will ensure your sheet lasts for hundreds of applications.

- If your primary focus is industrial or chemical processes: Document usage cycles and establish a clear replacement schedule based on visual inspection for scratches or degradation, not just time.

By understanding both its powerful capabilities and its practical limits, you can leverage a Teflon sheet as a reliable and cost-effective tool for achieving consistent, professional results.

Summary Table:

| Benefit | Key Property | Practical Outcome |

|---|---|---|

| Reusable for Many Cycles | Heat & Abrasion Resistance | Lowers cost per use vs. disposables |

| Protects Equipment | Non-stick, Chemically Inert | Extends machine life, reduces cleaning |

| Ensures Quality Results | Smooth, Even Heat Distribution | Prevents scorching, ensures clean releases |

| Reduces Waste | Long Lifespan | Fewer replacements, less material waste |

Maximize Your Process Efficiency with KINTEK PTFE Components

Are you looking for durable, high-performance PTFE sheets or custom components that deliver long-term value and reliability? Your application deserves the precision and quality that KINTEK provides.

We specialize in manufacturing PTFE components—including sheets, seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures you get a product engineered for exceptional durability and reusability, protecting your equipment and ensuring consistent results cycle after cycle.

Let's discuss how our custom fabrication services, from prototypes to high-volume orders, can provide a cost-effective solution for your specific needs.

Contact KINTEK today to request a quote or learn more about our PTFE solutions!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What are the key benefits of PTFE in custom fabrication? Unlock Performance in Extreme Conditions

- What are some common applications of machined PTFE? Leverage its Unique Properties for Demanding Applications

- What are the base characteristics of PTFE? Unlocking Extreme Performance in Friction, Temperature, and Chemical Resistance

- Why is PTFE suitable for cryogenic or high-temperature applications? Unmatched Thermal Stability from -450°F to 500°F

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications