Despite its reputation as a high-performance material, Polytetrafluoroethylene (PTFE) is defined by significant trade-offs. Its primary disadvantages are its difficult and unconventional manufacturing processes, its high relative cost, and its poor mechanical properties, including low strength and a tendency to deform under load.

The core challenge of PTFE is that its exceptional chemical inertness and thermal stability—the very properties that make it so valuable—also make it mechanically weak and difficult to process compared to conventional polymers.

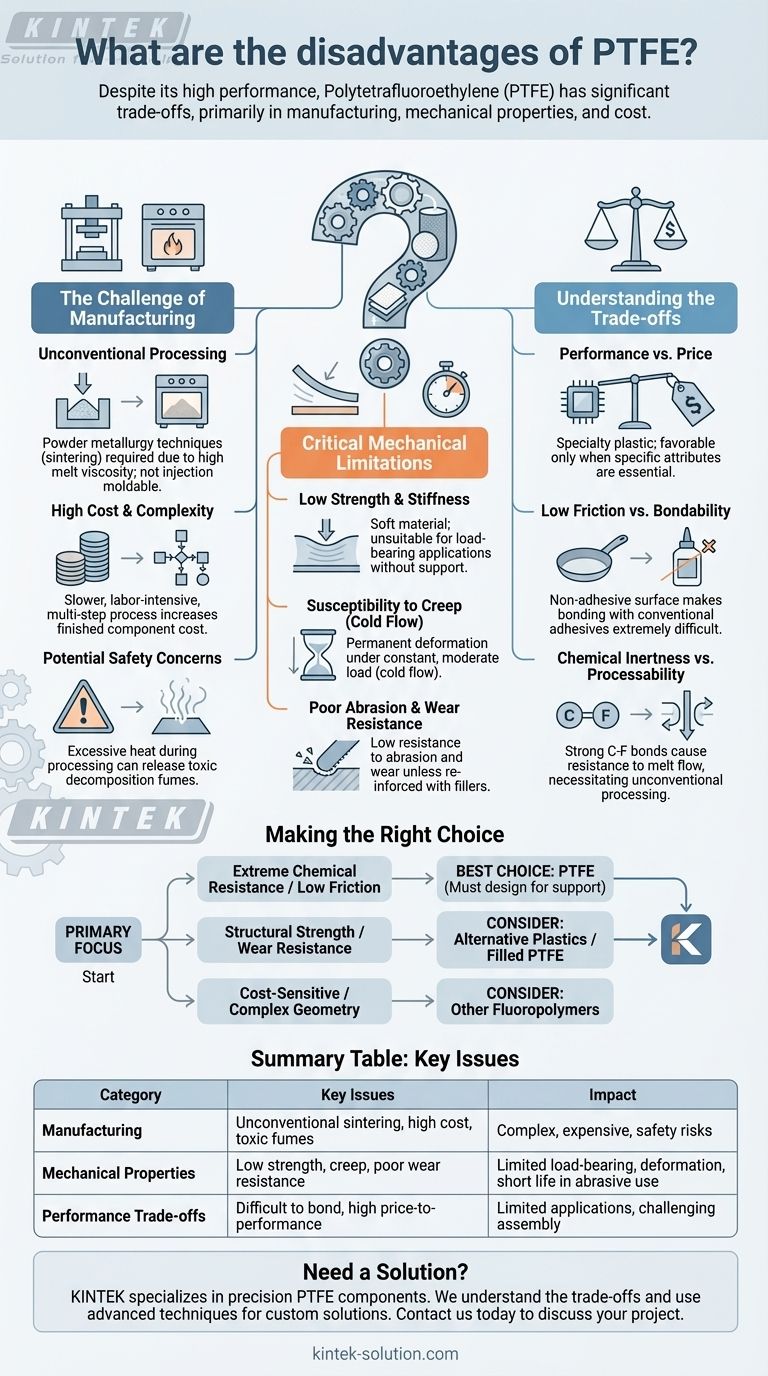

The Challenge of Manufacturing PTFE

PTFE cannot be processed using the typical melt-processing techniques common to most thermoplastics. This fundamental difference introduces complexity, cost, and potential safety issues.

Unconventional Processing Methods

Unlike plastics that can be easily injection molded, PTFE has an extremely high melt viscosity. It does not flow like a liquid when heated above its melting point.

Instead, it must be processed using techniques more akin to powder metallurgy. This involves compressing the powder into a preform and then heating it in an oven (a process called sintering) to fuse the particles.

High Cost and Complexity

This multi-step compression and sintering process is slower, more labor-intensive, and less suited for producing intricate parts than traditional injection molding. This inherent difficulty contributes significantly to the higher cost of finished PTFE components.

Potential Safety Concerns

While PTFE is stable at its recommended service temperatures, improper processing techniques involving excessive heat can cause it to decompose. This decomposition can release toxic fumes, requiring specialized ventilation and handling procedures during manufacturing.

Critical Mechanical Limitations

For all its resistance to chemicals and heat, PTFE is a mechanically weak material. This is its most significant limitation in engineering applications.

Low Strength and Stiffness

PTFE is a relatively soft material with low tensile strength and stiffness. It is unsuitable for applications that require load-bearing or structural integrity. Components can easily stretch and deform if not properly supported.

Susceptibility to Creep (Cold Flow)

One of the most well-known drawbacks of PTFE is its tendency to creep, or "cold flow." Even under a constant, moderate load at room temperature, the material will slowly and permanently deform over time. This makes it a poor choice for components like structural fasteners or high-pressure seals that are not properly contained.

Poor Abrasion and Wear Resistance

As a soft polymer, pure PTFE has poor resistance to abrasion and wear. While its low friction is an asset, it can be quickly worn away in applications involving contact with abrasive surfaces or high-speed moving parts unless it is reinforced with fillers.

Understanding the Trade-offs

The disadvantages of PTFE are not arbitrary flaws; they are direct consequences of the unique chemistry that gives the material its benefits.

Performance vs. Price

PTFE is not a low-cost polymer. Its complex manufacturing process and the raw materials involved place it in the category of a specialty, high-performance plastic. Its price-to-performance ratio is only favorable in applications where its specific attributes are essential.

Low Friction vs. Bondability

The famous non-adhesive, low-friction surface of PTFE is a double-edged sword. While it prevents materials from sticking, it also makes it extremely difficult to bond PTFE to other substrates using conventional adhesives. This requires special surface treatments like chemical etching, which adds cost and complexity.

Chemical Inertness vs. Processability

The incredibly strong carbon-fluorine bonds are what give PTFE its outstanding chemical resistance and thermal stability. However, these same powerful bonds are precisely why the material resists flowing when melted, forcing the use of unconventional and more difficult processing methods.

Making the Right Choice for Your Application

Selecting PTFE requires a clear understanding of whether its unique benefits outweigh its significant limitations for your specific goal.

- If your primary focus is extreme chemical resistance or low friction: PTFE is often the best choice for seals, gaskets, and non-stick linings, but you must design the component to support the material and prevent it from deforming under load.

- If your primary focus is structural strength or wear resistance: You should immediately look for alternative engineering plastics or consider filled grades of PTFE, which incorporate additives like glass, carbon, or bronze to improve mechanical properties.

- If your primary focus is cost-sensitive or complex part geometry: The difficult and expensive processing of PTFE may make other fluoropolymers or high-performance plastics a more practical choice.

Understanding these limitations is the key to successfully leveraging PTFE's remarkable capabilities where they matter most.

Summary Table:

| Disadvantage Category | Key Issues |

|---|---|

| Manufacturing | Unconventional sintering process, high cost, potential for toxic fume release |

| Mechanical Properties | Low strength, susceptibility to creep (cold flow), poor wear resistance |

| Performance Trade-offs | Difficult to bond, high price-to-performance ratio, limited to specific applications |

Need a high-performance PTFE component that overcomes these limitations?

KINTEK specializes in manufacturing precision PTFE components (seals, liners, labware, etc.) for the semiconductor, medical, laboratory, and industrial sectors. We understand the trade-offs of PTFE and use advanced fabrication techniques—from custom prototypes to high-volume production—to ensure your parts meet exact mechanical and chemical requirements.

Contact us today to discuss your project and get a solution tailored to your application's unique challenges.

Visual Guide

Related Products

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

People Also Ask

- How does PTFE function as an electrical insulator? Discover Its Superior Dielectric Properties

- What does PTFE stand for and what type of material is it? Discover Its Critical Role in High-Performance Applications

- What is PTFE and what are its key attributes? The Ultimate Guide to Its Properties & Uses

- Why is it difficult to glue materials to Teflon (PTFE)? Understand the Science & Solutions

- What are the key properties of PTFE? The Ultimate Material for Extreme Industrial Applications

- What is the water absorption rate of PTFE after 24 hours? Unlock Unmatched Material Stability

- What makes PTFE chemically inert? Discover the Molecular Secrets of its Unmatched Resistance

- What should users consider when using the chemical compatibility chart for PTFE? Ensure Material Safety and Reliability