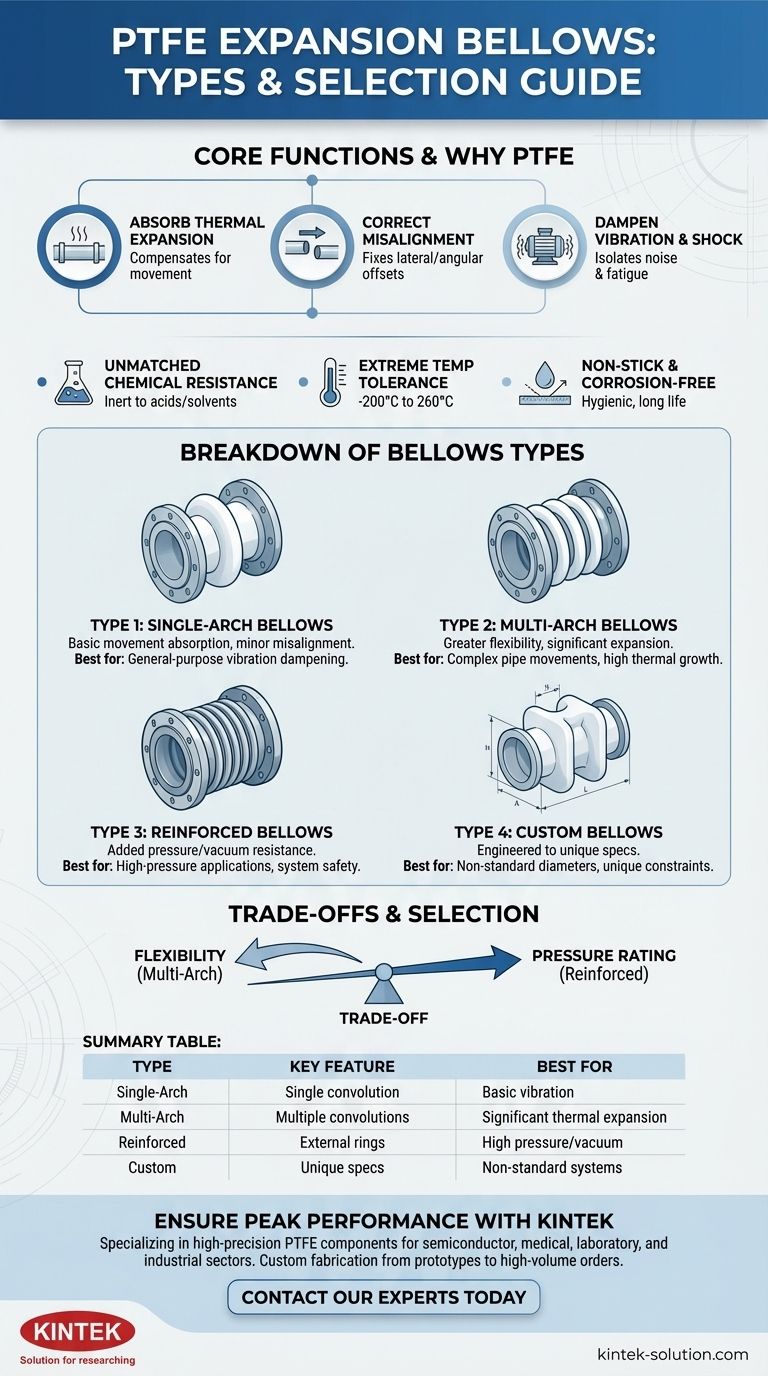

To put it simply, PTFE expansion bellows are categorized based on their physical construction, which directly corresponds to the type and magnitude of stress they are designed to handle. The primary types are single-arch for basic movement, multi-arch for greater flexibility, reinforced for high-pressure applications, and custom designs for unique system requirements.

The choice of a PTFE expansion bellow is not about finding the "best" type, but about accurately matching the bellow's design—its arches and reinforcement—to the specific mechanical, thermal, and chemical demands of your piping system.

The Core Problem Bellows Solve

Before examining the specific types, it's essential to understand the fundamental purpose of any expansion bellow. They are engineered to introduce flexibility into rigid piping systems, protecting them from damage.

Absorbing Thermal Expansion and Contraction

Piping systems expand and contract as the temperature of the fluid they carry fluctuates. A PTFE bellow acts as a flexible joint, compressing and extending to absorb this movement without transferring stress to the pipe flanges or connected equipment.

Correcting Misalignment

It is often difficult to achieve perfect alignment during pipe installation. Bellows compensate for initial lateral, angular, or axial misalignment, preventing stress on the system from the start.

Dampening Vibration and Shock

Pumps, motors, and other equipment generate vibrations that can travel through a piping system. A bellow isolates this vibration, reducing noise and preventing fatigue-related damage to the pipeline.

Why PTFE is the Material of Choice

The unique properties of Polytetrafluoroethylene (PTFE) make it an ideal material for expansion bellows, especially in demanding industrial environments.

Unmatched Chemical Resistance

PTFE is virtually inert to almost all industrial chemicals, acids, and solvents. This makes it essential for use in chemical processing, pharmaceutical, and food and beverage industries where corrosive materials are common.

Extreme Temperature Tolerance

PTFE bellows maintain their structural integrity and flexibility across an exceptionally wide temperature range, typically from -200°C to 260°C (-328°F to 500°F).

Non-Stick and Corrosion-Free

The material's non-stick surface prevents buildup and contamination, a critical feature for sanitary applications. Unlike metal joints, PTFE does not corrode, ensuring a long and reliable service life.

A Breakdown of Bellows Types

Each type of PTFE bellow is engineered to address a different level of operational stress and movement.

Type 1: Single-Arch Bellows

This is the most common and fundamental design, featuring a single convolution or "arch." It is the standard solution for absorbing small amounts of axial, lateral, or angular movement and is effective for general-purpose vibration dampening.

Type 2: Multi-Arch Bellows

As the name implies, these bellows feature two or more arches. Each additional arch increases the bellow's capacity to absorb movement. They are specified when a system experiences significant thermal expansion or requires greater flexibility to accommodate misalignment.

Type 3: Reinforced Bellows

Standard PTFE bellows have limited pressure and vacuum resistance. To handle these applications, reinforcing rings, often made of stainless steel, are added externally. These rings prevent the bellows from bursting under high pressure or collapsing under vacuum conditions.

Type 4: Custom Bellows

Many industrial systems have unique constraints, such as non-standard pipe diameters, unusual movement requirements, or extreme chemical exposure. Custom bellows are engineered specifically for these applications, tailoring the number of arches, reinforcement, and overall dimensions to the precise need.

Understanding the Trade-offs

Choosing the right bellow requires balancing flexibility with strength. This is the primary trade-off you must consider.

Flexibility vs. Pressure Rating

Adding more arches to a bellow increases its ability to absorb movement but simultaneously decreases its pressure rating. The deeper convolutions that allow for flexibility also create weaker points when subjected to internal pressure.

Cost vs. Complexity

A simple, single-arch bellow is a cost-effective solution for basic applications. As you add arches, reinforcement, or require custom engineering, the complexity and cost of the component increase significantly. Over-engineering a solution is an unnecessary expense.

Material Limitations

While PTFE has exceptional chemical and thermal resistance, it has lower mechanical strength compared to metal. In extremely high-pressure or high-impact environments, even a reinforced PTFE bellow may not be suitable, and a different material like stainless steel might be required.

Making the Right Choice for Your Goal

Your selection should be guided by a clear analysis of your system's specific operational demands.

- If your primary focus is basic vibration control or minor misalignment: A single-arch bellow is the most practical and economical choice.

- If your primary focus is managing significant thermal expansion or complex pipe movements: A multi-arch design provides the necessary extended range of motion.

- If your primary focus is operating under high pressure or vacuum conditions: A reinforced bellow is non-negotiable to ensure system safety and integrity.

- If your primary focus is fitting a non-standard or uniquely challenging system: Investing in a custom-engineered bellow is the only way to guarantee a proper and safe fit.

Ultimately, a precise understanding of your system's operational stress is the key to selecting the correct PTFE expansion bellow.

Summary Table:

| Bellow Type | Key Feature | Best For |

|---|---|---|

| Single-Arch | Single convolution | Basic vibration dampening, minor misalignment |

| Multi-Arch | Multiple convolutions | Significant thermal expansion, complex movements |

| Reinforced | External reinforcing rings | High-pressure or vacuum applications |

| Custom | Engineered to unique specs | Non-standard diameters, extreme conditions |

Ensure Peak Performance and Reliability

Selecting the right PTFE expansion bellow is critical for the safety and longevity of your piping system. The wrong choice can lead to premature failure, costly downtime, and potential safety hazards.

KINTEK specializes in manufacturing high-precision PTFE components, including a full range of expansion bellows for the semiconductor, medical, laboratory, and industrial sectors. We understand the unique stresses your systems face. Our expertise ensures you get a bellow that provides the perfect balance of flexibility, pressure rating, and chemical resistance for your specific application.

We offer custom fabrication from prototypes to high-volume orders, guaranteeing a perfect fit and optimal performance.

Don't leave your system's integrity to chance. Contact our experts today for a consultation and let us help you specify the ideal PTFE expansion bellow.

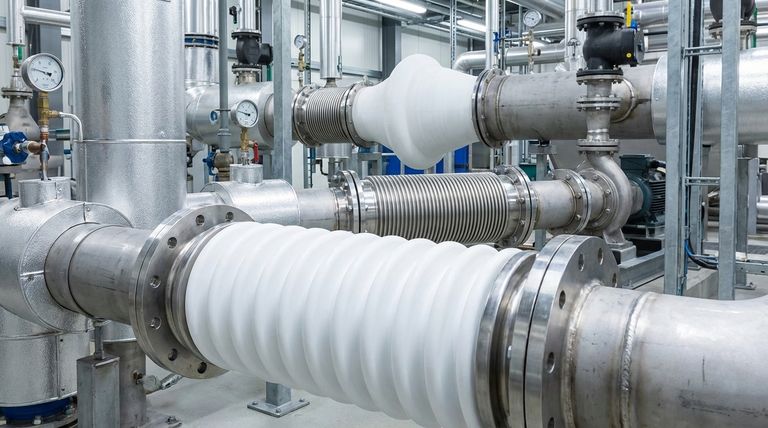

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems