In terms of service life, PTFE oil seals significantly outperform conventional oil seals, especially in demanding operational environments. This longevity is not a minor improvement; it is a direct result of PTFE's fundamental material properties, which provide superior resistance to heat, chemicals, and wear, preventing the common failure modes that shorten the life of traditional rubber seals.

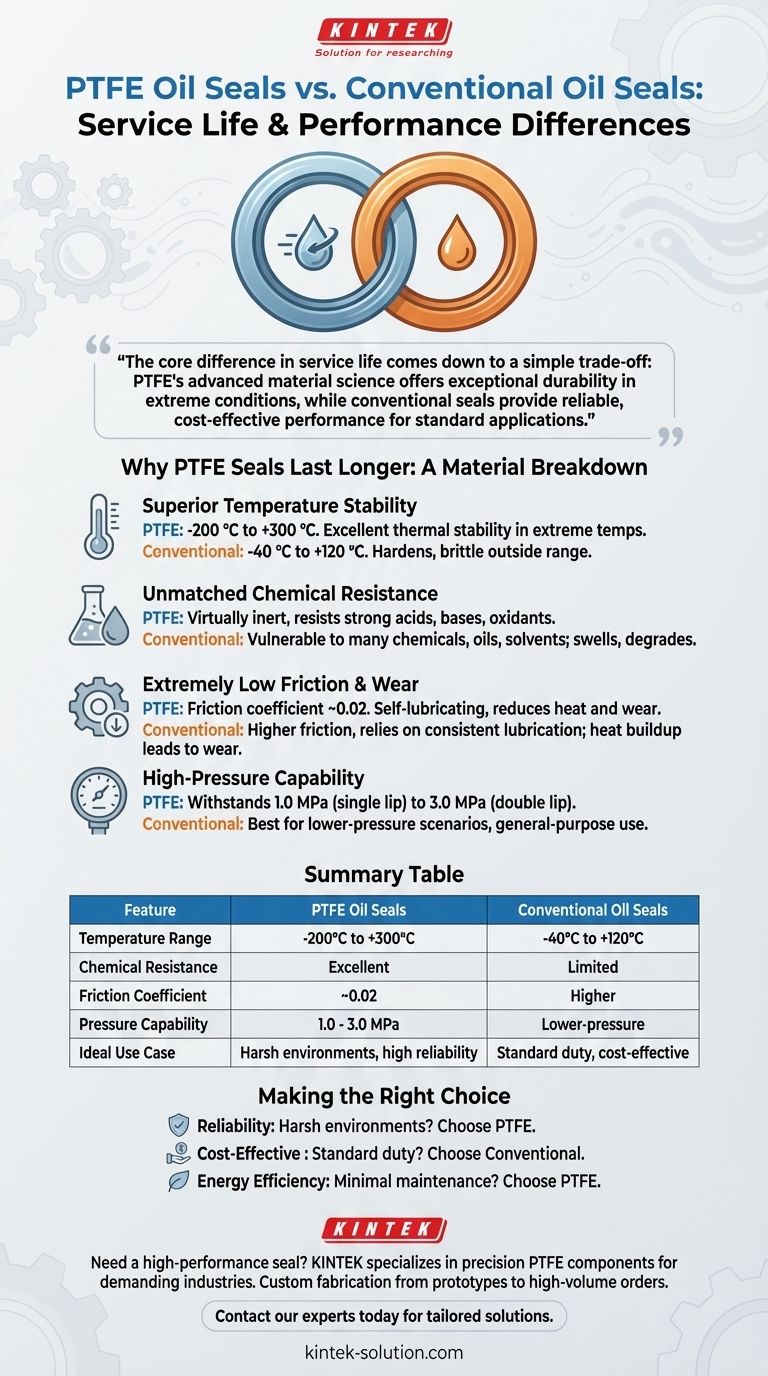

The core difference in service life comes down to a simple trade-off: PTFE's advanced material science offers exceptional durability in extreme conditions, while conventional seals provide reliable, cost-effective performance for standard applications. Choosing the right one requires matching the seal's capabilities to your specific operational demands.

Why PTFE Seals Last Longer: A Material Breakdown

The extended service life of a PTFE seal is not based on a single feature but on a combination of its inherent material characteristics. These properties allow it to withstand conditions that would quickly degrade a conventional seal made from nitrile or other elastomers.

Superior Temperature Stability

PTFE seals demonstrate excellent thermal stability, operating effectively in extreme temperatures ranging from -200 °C to +300 °C.

In contrast, conventional rubber seals have a much narrower operating window, typically between -40 °C and +120 °C. Exposure to temperatures outside this range causes them to harden, become brittle, and ultimately fail.

Unmatched Chemical Resistance

PTFE is virtually inert, resisting erosion from almost all chemicals, including strong acids, bases, and powerful oxidants. This makes it ideal for harsh chemical processing environments.

Conventional rubber seals are vulnerable to many common industrial chemicals, oils, and solvents, which can cause them to swell, soften, or dissolve over time, leading to leakage.

Extremely Low Friction and Wear

PTFE has an exceptionally low friction coefficient of approximately 0.02. This self-lubricating property drastically reduces heat generation and wear during operation, minimizing energy loss and extending the seal's life.

Conventional seals have a higher friction coefficient. They rely on a consistent lubricating oil film to maintain their seal and prevent premature wear from heat buildup. If lubrication is insufficient, they can degrade quickly.

High-Pressure Capability

PTFE seals are engineered for high-pressure applications, capable of withstanding pressures from 1.0 MPa (single lip) to 3.0 MPa (double lip).

Conventional oil seals are designed for lower-pressure scenarios and are best suited for general-purpose mechanical sealing needs where pressure is not a primary stress factor.

Understanding the Trade-offs

While PTFE offers superior performance in almost every category, it is not always the necessary choice. Understanding the primary trade-off—cost versus performance—is critical for making a sound engineering decision.

When Conventional Seals Are the Right Choice

Conventional rubber oil seals are highly cost-effective and perform exceptionally well in a vast number of common applications.

For machinery operating under moderate temperatures, low pressures, and without exposure to aggressive chemicals, a conventional seal provides reliable performance at a much lower initial cost.

The Cost-Performance Equation

The higher price of a PTFE seal is an investment in reliability and reduced downtime. In mission-critical or harsh-environment equipment, the cost is easily justified by preventing costly failures and maintenance cycles.

If the operating conditions do not demand extreme performance, the added expense of PTFE provides no tangible benefit, making a conventional seal the more logical and economical choice.

Making the Right Choice for Your Application

Selecting the correct seal requires a clear understanding of your equipment's operating environment and performance goals.

- If your primary focus is reliability in harsh environments: Choose a PTFE seal for its unmatched resistance to extreme temperatures, aggressive chemicals, and high pressures.

- If your primary focus is cost-effectiveness for standard duty: A conventional rubber seal provides dependable performance for general-purpose applications without the premium cost.

- If your primary focus is energy efficiency and minimal maintenance: The self-lubricating, low-friction properties of PTFE will reduce operational costs and extend service intervals.

Ultimately, an informed decision is based on a clear-eyed assessment of the application's demands versus the material's capabilities.

Summary Table:

| Feature | PTFE Oil Seals | Conventional Oil Seals |

|---|---|---|

| Temperature Range | -200 °C to +300 °C | -40 °C to +120 °C |

| Chemical Resistance | Excellent (resists most acids, bases, solvents) | Limited (vulnerable to many chemicals) |

| Friction Coefficient | ~0.02 (self-lubricating) | Higher (requires consistent lubrication) |

| Pressure Capability | 1.0 MPa to 3.0 MPa | Best for lower-pressure scenarios |

| Ideal Use Case | Harsh environments, extreme conditions, high reliability | Standard duty, cost-effective applications |

Need a high-performance seal that extends service life and reduces downtime?

KINTEK specializes in manufacturing precision PTFE components, including seals, liners, and labware, for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in custom fabrication—from prototypes to high-volume orders—ensures you get a seal perfectly matched to your operational demands, whether you require the extreme durability of PTFE or a cost-effective conventional solution.

Contact our experts today to discuss your specific application and receive a tailored solution that maximizes reliability and value.

Visual Guide

Related Products

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the benefits of using PTFE seals? Unmatched Chemical & Temperature Resistance

- What are some common PTFE seal types used in industrial applications? Explore Solutions for Every Motion & Environment

- What are the key properties of PTFE that make it suitable for sealing applications? | High-Performance Seals for Extreme Conditions

- What are the key properties of PTFE that make it suitable for seals? Unlock Reliability in Extreme Conditions

- How do FEP and PTFE encapsulated O-rings contribute to equipment longevity? Prevent Costly Downtime with Superior Seals