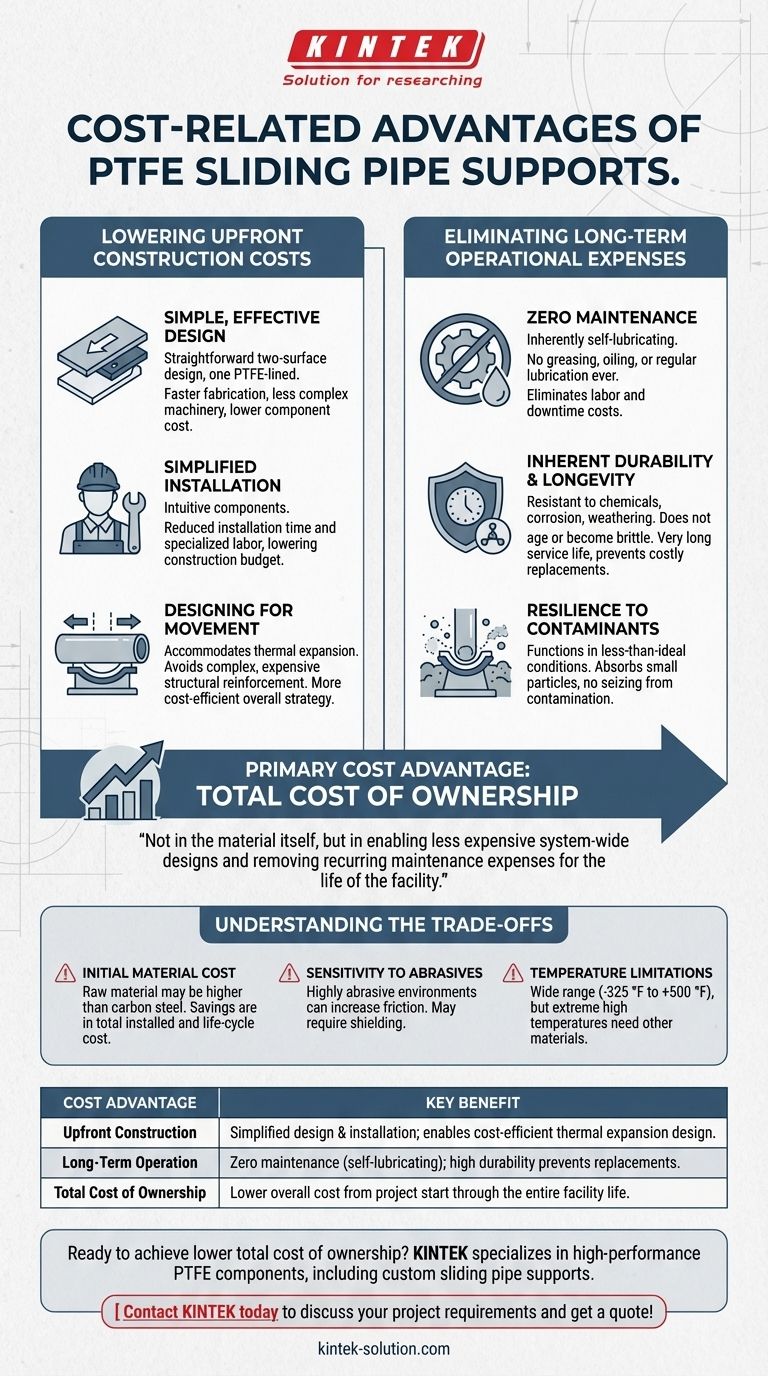

From a cost perspective, PTFE sliding pipe supports offer significant advantages by reducing both upfront construction expenses and long-term operational costs. Their simple design is easy to fabricate and install, and more importantly, they allow engineers to design for thermal expansion rather than strain. This approach avoids the need for more complex and expensive structural reinforcements, while their self-lubricating nature completely eliminates ongoing maintenance requirements.

The primary cost advantage of PTFE pipe supports is not in the material itself, but in the total cost of ownership. They enable less expensive system-wide designs and remove recurring maintenance expenses for the life of the facility.

Lowering Upfront Construction Costs

The initial project budget is often where the benefits of PTFE supports are first realized. The savings come from a combination of simplified components and a more efficient overall engineering strategy.

Simple, Effective Design

The fundamental design of a PTFE slide plate is straightforward. It consists of two surfaces, one lined with PTFE, designed to slide against each other.

This simplicity means fabrication is faster and requires less complex machinery, directly lowering the manufacturing cost of the support itself.

Simplified Installation

Because the components are simple and intuitive, installation is typically faster and requires less specialized labor.

Reducing installation time and complexity is a direct and immediate way to lower the overall construction budget.

Designing for Movement, Not Strain

This is the most critical cost-saving factor in the design phase. Pipes expand and contract with temperature changes, creating immense force.

Instead of building a rigid, heavily reinforced system to resist this force (a high-cost approach), PTFE supports allow the pipe to move freely. This strategy of accommodating expansion is fundamentally more cost-efficient, reducing the need for extra steel and complex structural engineering.

Eliminating Long-Term Operational Expenses

Once a system is operational, PTFE supports continue to provide financial benefits by minimizing or eliminating the costs associated with upkeep and replacement.

Zero Maintenance Requirements

PTFE is an inherently self-lubricating material. It has one of the lowest coefficients of friction of any solid.

This property means the supports require no greasing, oiling, or any form of regular lubrication for their entire service life. This eliminates costs related to labor, materials, and equipment downtime associated with maintenance schedules.

Inherent Durability and Longevity

PTFE is highly resistant to chemicals, corrosion, and weathering. It does not age or become brittle over time like many other materials.

This exceptional durability ensures a very long service life, preventing the need for costly replacements and the associated labor and shutdown periods.

Resilience to Contaminants

The material is designed to function even in less-than-ideal conditions. Small dirt particles are often absorbed into the PTFE surface without compromising its low-friction properties.

This resilience means that unlike traditional mechanical bearings that can seize up from contamination, PTFE supports continue to operate reliably with only simple protection needed against significant debris.

Understanding the Trade-offs

While highly advantageous, it is important to understand the context and limitations to make a fully informed decision. No solution is perfect for every application.

Initial Material Cost

The raw material cost of PTFE may be higher than that of a basic carbon steel slide plate. The savings are realized in the total installed cost and life-cycle cost, not necessarily in the price of the raw component itself.

Sensitivity to Abrasives

While PTFE can handle minor dirt, highly abrasive environments (like heavy sand or sharp particulates) can score the surface and increase the friction coefficient over time. In these specific cases, simple shielding or alternative designs may be necessary.

Temperature Limitations

PTFE has a very wide operating temperature range (from -325 °F to +500 °F), which covers the vast majority of piping applications. However, for extreme high-temperature systems beyond this range, other materials like graphite must be considered.

Making the Right Choice for Your Project

Choosing the right support system depends on balancing upfront capital with long-term operational budgets.

- If your primary focus is minimizing upfront capital expenditure: PTFE supports enable a more efficient system design that accommodates thermal expansion, reducing overall structural and installation costs.

- If your primary focus is reducing long-term operational costs: The self-lubricating, zero-maintenance nature of PTFE completely eliminates recurring expenses for the entire life of the piping system.

- If your primary focus is system reliability and longevity: PTFE's inherent resistance to corrosion, chemicals, and aging provides a "fit and forget" solution that prevents costly failures and replacements.

Ultimately, specifying PTFE pipe supports is an investment in a lower total cost of ownership through smarter engineering and maintenance-free operation.

Summary Table:

| Cost Advantage | Key Benefit |

|---|---|

| Upfront Construction | Simplified design & installation; enables cost-efficient thermal expansion design. |

| Long-Term Operation | Zero maintenance (self-lubricating); high durability prevents replacements. |

| Total Cost of Ownership | Lower overall cost from project start through the entire facility life. |

Ready to achieve lower total cost of ownership for your piping systems?

KINTEK specializes in manufacturing high-performance PTFE components, including custom sliding pipe supports. Our precision production ensures reliable, maintenance-free operation for the semiconductor, medical, laboratory, and industrial sectors. From prototypes to high-volume orders, we deliver the quality you need to optimize costs.

Contact KINTEK today to discuss your project requirements and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers