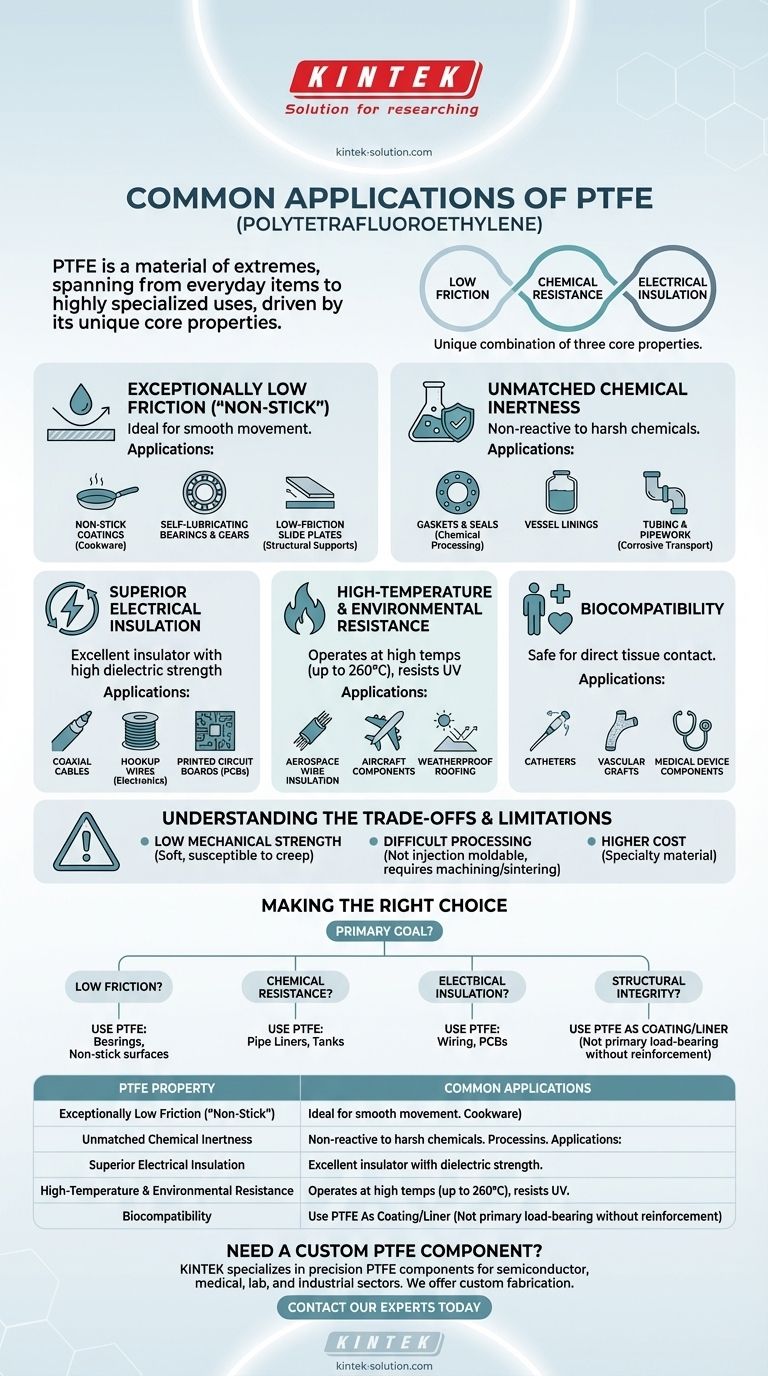

At its core, Polytetrafluoroethylene (PTFE) is a material of extremes. Its applications span from everyday non-stick cookware and stain-resistant fabrics to highly specialized uses in aerospace, chemical processing, and medicine. You can find it lining vessels containing corrosive acids, insulating high-frequency cables, and creating low-friction surfaces for industrial bearings and medical implants.

PTFE's vast range of applications is not accidental. It stems directly from a unique combination of three core properties: an almost complete resistance to chemicals, one of the lowest coefficients of friction of any solid, and excellent performance as a thermal and electrical insulator.

Why PTFE Is So Versatile: A Breakdown by Property

To understand where to use PTFE, you must first understand its fundamental characteristics. Its applications are a direct result of its inherent chemical and physical properties.

Exceptionally Low Friction (The "Non-Stick" Property)

This is PTFE's most famous characteristic. The bond between its carbon and fluorine atoms is so strong that other molecules slide off its surface with minimal resistance.

This property makes it the ideal choice for applications where smooth movement is critical. Examples include non-stick coatings for cookware and industrial bakeware, self-lubricating bearings and gears, and low-friction slide plates for structural supports.

Unmatched Chemical Inertness

PTFE is non-reactive to a vast spectrum of chemicals, acids, and bases, even at high temperatures. This makes it an invaluable material for harsh industrial environments.

It is used to create gaskets, seals, and vessel linings in the chemical processing industry. It's also used for tubing and pipework that transports highly corrosive or reactive materials, protecting both the substance and the surrounding infrastructure.

Superior Electrical Insulation

PTFE is an excellent electrical insulator with a very high dielectric strength. It resists the flow of electricity and maintains its properties across a wide range of frequencies.

This makes it essential for high-performance electronics and wiring. Common applications include insulation for coaxial cables, hookup wires in computers, and as a substrate for printed circuit boards (PCBs) used in microwave and radio frequency applications.

High-Temperature and Environmental Resistance

PTFE can operate continuously at high temperatures (up to 260°C or 500°F) without significant degradation. It is also highly resistant to UV radiation and weathering.

These features allow it to be used for insulating wires in jet engines, coating external aircraft components, and as a protective, weatherproof coating for the roofs of large structures like stadiums and airports.

Biocompatibility

The human body does not react to PTFE, making it a safe choice for medical applications that involve direct contact with tissue.

It is frequently used to manufacture catheters, vascular grafts, and components for syringes and other medical devices where a sterile, non-reactive surface is paramount.

Understanding the Trade-offs and Limitations

While extremely capable, PTFE is not the solution for every problem. Understanding its limitations is critical for proper application.

Low Mechanical Strength

PTFE is a relatively soft material. It can be susceptible to "creep," or deformation under a sustained load, and has poor abrasion resistance compared to harder polymers. It is rarely used for primary structural components.

Difficult Processing

PTFE has a very high melting point and high melt viscosity, which means it cannot be processed using conventional techniques like injection molding. It is typically machined from stock shapes (rods, sheets) or formed through compression and sintering.

Higher Cost

Compared to common commodity plastics like polyethylene or polypropylene, PTFE is a more expensive specialty material. Its cost is justified by its unique performance in demanding environments where other materials would fail.

Making the Right Choice for Your Application

Selecting the right material requires matching its properties to your primary goal.

- If your primary focus is reducing friction: PTFE is an elite choice for bearings, non-stick surfaces, and self-lubricating mechanical parts.

- If your primary focus is chemical resistance: It is often the default material for lining pipes, tanks, and valves in corrosive environments.

- If your primary focus is high-frequency electrical insulation: Its low dielectric constant and high breakdown voltage are ideal for critical wiring and PCBs.

- If your primary focus is structural integrity: Use PTFE as a coating, liner, or component, not as the primary load-bearing material unless it is reinforced with fillers like glass or carbon.

Understanding these core principles allows you to leverage PTFE's exceptional properties to solve a remarkably wide range of engineering challenges.

Summary Table:

| PTFE Property | Common Applications |

|---|---|

| Low Friction | Non-stick coatings, bearings, slide plates |

| Chemical Inertness | Seals, gaskets, vessel linings, chemical tubing |

| Electrical Insulation | Coaxial cables, PCBs, high-performance wiring |

| High-Temp Resistance | Aerospace components, wire insulation |

| Biocompatibility | Catheters, vascular grafts, medical device parts |

Need a custom PTFE component for your demanding application?

KINTEK specializes in manufacturing precision PTFE components—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. We offer custom fabrication from prototypes to high-volume orders, ensuring your parts meet the exact requirements for chemical resistance, low friction, and insulation.

Contact our experts today to discuss your project and get a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- Why is PTFE suitable for cryogenic or high-temperature applications? Unmatched Thermal Stability from -450°F to 500°F