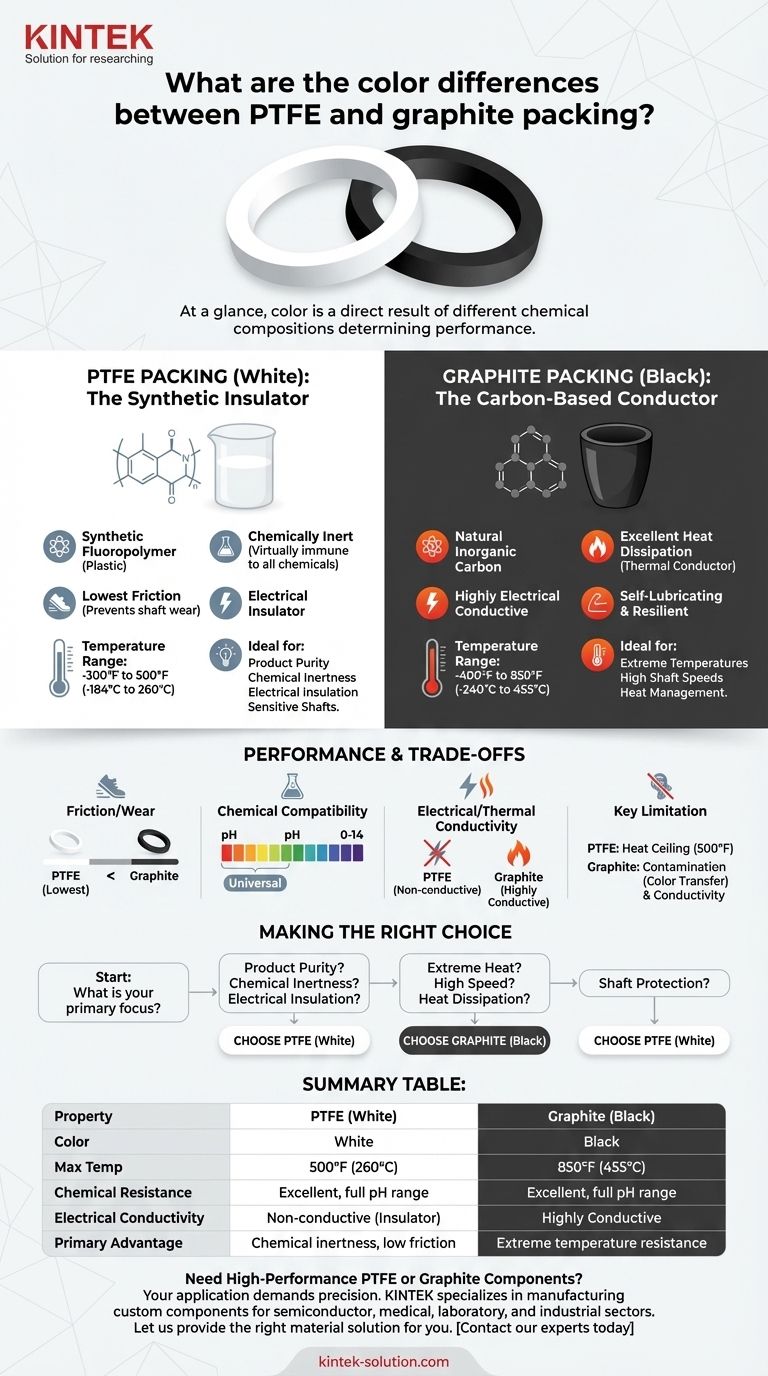

At a glance, the most striking difference between these two packing materials is their color. PTFE (polytetrafluoroethylene) packing is characteristically white, while graphite packing is always black. This color difference is not cosmetic; it is a direct result of their fundamentally different chemical compositions, which dictate their performance in industrial applications.

The color is a simple visual cue for a much deeper distinction: PTFE is a synthetic, non-conductive polymer prized for its chemical inertness, while graphite is a pure carbon material valued for its extreme temperature resistance and conductivity.

Beyond Color: Understanding the Core Materials

The choice between white PTFE and black graphite packing goes far beyond aesthetics. It's a choice between two materials with distinct origins and properties that make them suitable for very different operational demands.

PTFE: The Synthetic Insulator

PTFE is a synthetic fluoropolymer, a type of plastic. Its brilliant white color is indicative of its pure, stable, and non-reactive polymer structure.

This composition gives PTFE its most valued characteristics: it is one of the most chemically inert substances known and possesses the lowest coefficient of friction of any solid material. It is also an excellent electrical insulator.

Graphite: The Carbon-Based Conductor

Graphite is a natural, inorganic form of pure carbon. Its deep black color is inherent to its carbon base.

As a material, graphite is renowned for its ability to withstand extreme temperatures and its self-lubricating properties. Unlike PTFE, graphite is highly conductive, both thermally and electrically, allowing it to dissipate heat effectively from the shaft.

Performance Under Pressure: A Technical Comparison

Understanding how each material behaves under specific stressors is critical for selecting the correct packing for your pump or valve.

Temperature Resistance

Graphite has a significant advantage in high-temperature applications. It can handle a broad range from -400°F to 850°F (-240°C to 455°C).

PTFE has a more limited operational window, suitable for temperatures between -300°F and 500°F (-184°C to 260°C).

Friction and Shaft Wear

PTFE has the lowest coefficient of friction available in a packing material. This makes it exceptionally good at preventing wear and scoring on shafts and sleeves.

Graphite also has a low coefficient of friction and is self-lubricating, but PTFE is superior in pure friction reduction.

Chemical Compatibility

Both materials exhibit excellent chemical resistance across the full pH range of 0-14.

PTFE is virtually immune to all chemicals, with the rare exception of molten alkali metals. This makes it a primary choice for aggressive and corrosive services.

Electrical and Thermal Conductivity

This is a critical point of divergence. PTFE is non-conductive, making it a perfect electrical and thermal insulator.

Graphite is highly conductive. This allows it to draw heat away from the shaft, which is beneficial at high shaft speeds, but makes it unsuitable for applications requiring electrical insulation.

Understanding the Trade-offs

Neither material is a universal solution. The advantages of one are often the limitations of the other.

The PTFE Limitation: The Heat Ceiling

The primary trade-off for PTFE's superior chemical inertness and low friction is its relatively low temperature limit of 500°F. Pushing it beyond this point will cause it to degrade rapidly.

The Graphite Consideration: Contamination and Conductivity

While excellent for heat, graphite's black carbon composition means it can transfer color. This makes it unsuitable for applications in food, pharmaceutical, or other industries where product purity is paramount.

Furthermore, its high electrical conductivity can be a significant liability in applications where stray electrical currents must be avoided.

Making the Right Choice for Your Application

Selecting the correct packing requires matching the material's properties to the operational demands of your system.

- If your primary focus is product purity and chemical inertness: PTFE is the clear choice, as its white, non-staining composition and near-universal chemical resistance are unmatched.

- If your primary focus is managing high temperatures or high shaft speeds: Graphite is the superior option due to its exceptional thermal stability and ability to dissipate heat.

- If your primary focus is protecting sensitive shafts from wear: PTFE's extremely low coefficient of friction offers the best protection against scoring.

- If electrical insulation is a critical safety requirement: You must choose the non-conductive properties of PTFE.

By understanding these fundamental differences, you can confidently select the packing that ensures the safety, efficiency, and longevity of your equipment.

Summary Table:

| Property | PTFE Packing (White) | Graphite Packing (Black) |

|---|---|---|

| Color | White | Black |

| Max Temperature | 500°F (260°C) | 850°F (455°C) |

| Chemical Resistance | Excellent, full pH range | Excellent, full pH range |

| Electrical Conductivity | Non-conductive (Insulator) | Highly Conductive |

| Primary Advantage | Chemical inertness, low friction | Extreme temperature resistance |

Need High-Performance PTFE or Graphite Components?

Your application demands precision. The choice between PTFE's chemical inertness and graphite's high-temperature resilience is critical for your system's safety and efficiency.

KINTEK specializes in manufacturing custom PTFE and graphite components—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. We deliver the precision you require, from initial prototypes to high-volume production runs.

Let us provide the right material solution for you. Contact our experts today to discuss your specific requirements and get a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Bottles for Diverse Industrial Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- When and by whom was PTFE discovered? A Tale of Accidental Innovation

- How is PTFE used in industrial processes? Maximize Safety and Efficiency

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- What are some applications of CNC machined PTFE parts? Critical Components for Medical, Electrical & Food Industries

- What is the hardness range of PTFE on the Shore D scale? Leveraging Its Softness for Superior Performance