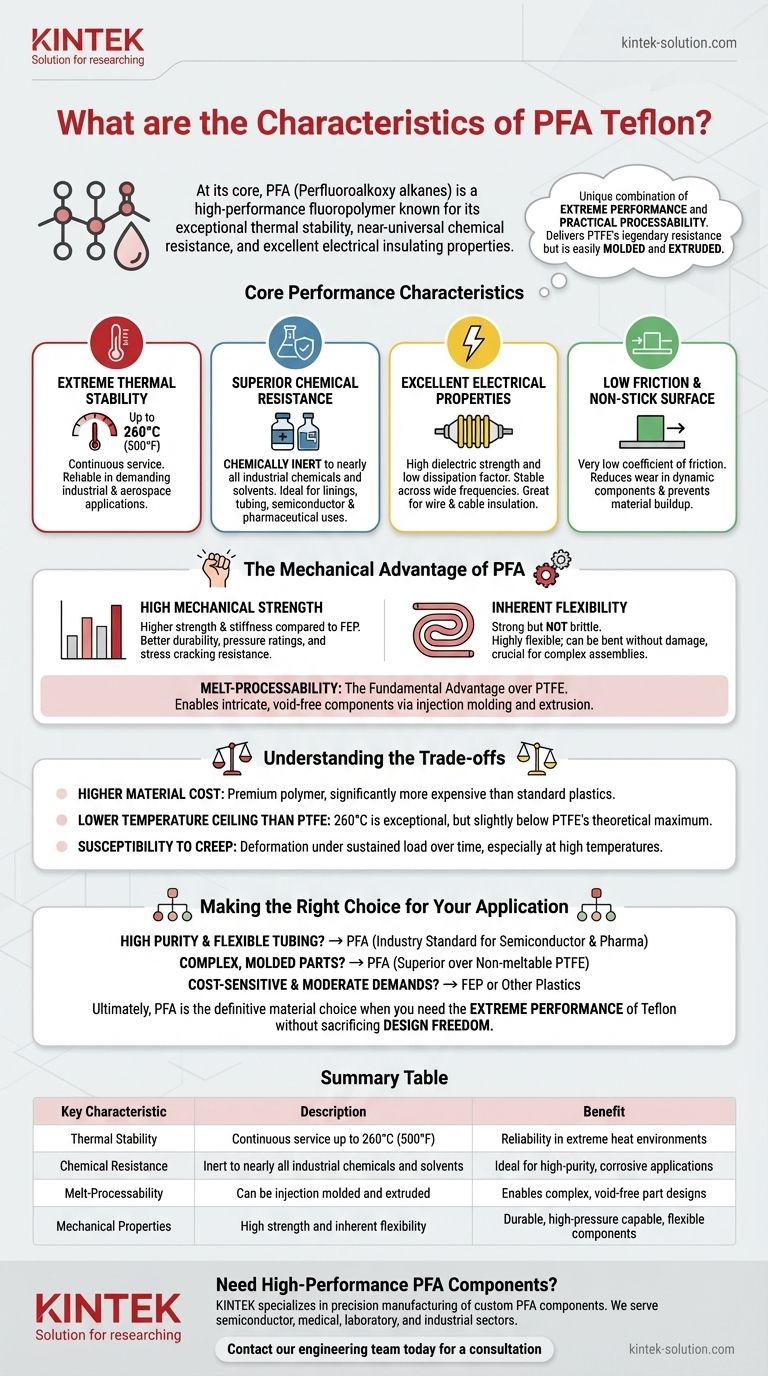

At its core, PFA (Perfluoroalkoxy alkanes) is a high-performance fluoropolymer known for its exceptional thermal stability, near-universal chemical resistance, and excellent electrical insulating properties. It combines the key benefits of PTFE with the significant advantage of being melt-processable, making it one of the most versatile materials for extreme environments.

The defining characteristic of PFA is its unique combination of extreme performance and practical processability. It delivers the legendary chemical and temperature resistance of PTFE but can be easily molded and extruded into complex shapes, a capability PTFE lacks.

Core Performance Characteristics

PFA's properties make it a default choice for applications where failure is not an option. Its performance is rooted in a few key areas.

Extreme Thermal Stability

PFA maintains its properties across a very wide temperature range. It is capable of continuous service at temperatures up to 260°C (500°F).

This high-temperature stability ensures reliability in demanding industrial, chemical, and aerospace applications.

Superior Chemical Resistance

Like other fluoropolymers, PFA is chemically inert to nearly all industrial chemicals and solvents.

This makes it an ideal material for linings, tubing, and components used in chemical processing, semiconductor manufacturing, and pharmaceutical applications where purity and resistance to corrosion are critical.

Excellent Electrical Properties

PFA is an outstanding electrical insulator with high dielectric strength and a low dissipation factor.

Its electrical properties are stable across a wide range of frequencies and temperatures, making it highly valuable for wire and cable insulation, particularly in plenum spaces or high-frequency applications.

Low Friction and Non-Stick Surface

PFA possesses a very low coefficient of friction and excellent non-stick properties, similar to other forms of Teflon.

This reduces wear in dynamic components and prevents material buildup in fluid handling systems, ensuring consistent flow and easy cleaning.

The Mechanical Advantage of PFA

The description of PFA as both "strong" and "flexible" can seem contradictory but highlights its key mechanical advantages over other materials.

High Mechanical Strength

Compared to a similar fluoropolymer like FEP, PFA offers higher mechanical strength and stiffness.

This translates to better durability, higher pressure ratings in tubing, and improved resistance to stress cracking, especially at elevated temperatures.

Inherent Flexibility

Despite its strength, PFA is not brittle. It is a highly flexible material that can be bent and routed without damage.

This is crucial for applications like flexible tubing, bellows, and wire insulation that must navigate complex assemblies.

The Power of Melt-Processability

Perhaps the most important mechanical characteristic of PFA is that it can be melt-processed using conventional techniques like injection molding and extrusion.

This is a fundamental advantage over PTFE, which cannot be processed this way. It allows for the creation of intricate, void-free components like valve bodies, pump housings, and encapsulated O-rings that would be impossible to fabricate from PTFE.

Understanding the Trade-offs

While PFA is a premier material, its selection requires an understanding of its limitations and cost.

Higher Material Cost

PFA is a premium polymer, and its cost reflects its high performance and complex manufacturing process. It is significantly more expensive than standard plastics and even other fluoropolymers like FEP.

Lower Temperature Ceiling than PTFE

While its 260°C service temperature is exceptional, it is slightly below the maximum theoretical service temperature of PTFE (polytetrafluoroethylene). For static applications at the absolute highest temperatures, PTFE may still have an edge.

Susceptibility to Creep

Like most thermoplastics, PFA can exhibit creep (deformation under sustained load) over time, particularly at elevated temperatures. This must be a design consideration for structural components under constant stress.

Making the Right Choice for Your Application

Selecting PFA is a decision driven by the specific demands of the environment.

- If your primary focus is high purity and flexible tubing for harsh chemicals: PFA is the industry standard in semiconductor and pharmaceutical manufacturing for this exact purpose.

- If your primary focus is creating complex, molded parts for extreme environments: PFA’s melt-processability makes it the superior choice over non-meltable materials like PTFE.

- If your primary focus is cost-sensitive applications with moderate demands: A less robust fluoropolymer like FEP or a different high-performance plastic may be a more suitable choice.

Ultimately, PFA is the definitive material choice when you need the extreme performance of Teflon without sacrificing design freedom.

Summary Table:

| Key Characteristic | Description | Benefit |

|---|---|---|

| Thermal Stability | Continuous service up to 260°C (500°F) | Reliability in extreme heat environments |

| Chemical Resistance | Inert to nearly all industrial chemicals and solvents | Ideal for high-purity, corrosive applications |

| Melt-Processability | Can be injection molded and extruded | Enables complex, void-free part designs impossible with PTFE |

| Mechanical Properties | High strength and inherent flexibility | Durable, high-pressure capable, and suitable for flexible components |

Need High-Performance PFA Components?

PFA Teflon is the definitive choice for applications demanding extreme chemical resistance, high-temperature stability, and complex design geometry. KINTEK specializes in the precision manufacturing of custom PFA components—from seals and liners to complex labware and tubing.

We serve the semiconductor, medical, laboratory, and industrial sectors, delivering custom fabrication from prototypes to high-volume production runs.

Let's discuss how our PFA expertise can solve your most challenging application requirements.

Contact our engineering team today for a consultation

Visual Guide

Related Products

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

People Also Ask

- What are the common applications of PTFE balls? Leverage Unmatched Chemical Resistance & Low Friction

- What makes PTFE balls ideal for chemical applications? Unmatched Inertness for Demanding Environments

- What size range do PTFE balls come in? A Guide from 3mm to 100mm

- What temperature range can PTFE balls withstand? Unlock Extreme Thermal Stability from -200°C to 260°C

- What are the tolerances for PTFE balls based on size? Precision vs. Standard Grade Explained