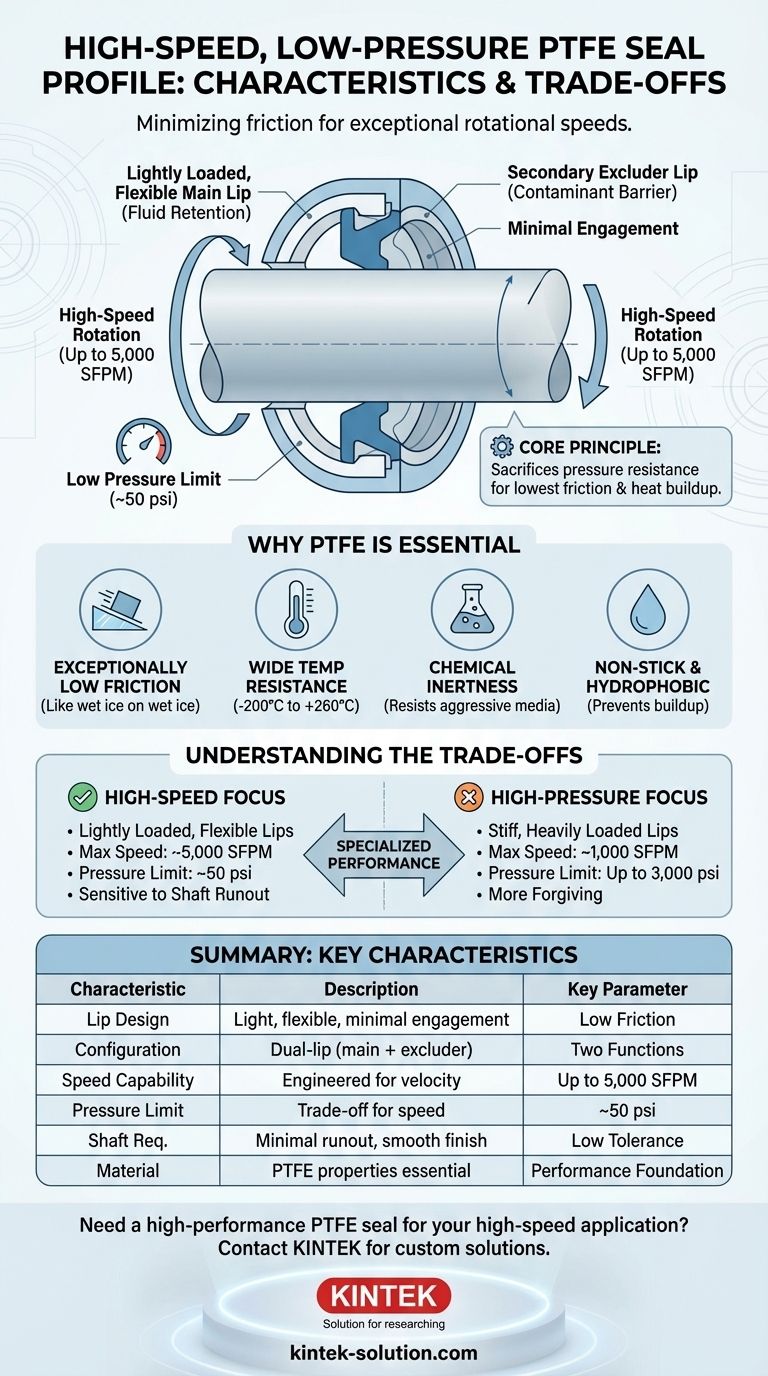

At its core, a high-speed, low-pressure PTFE seal profile is defined by its lightly loaded and highly flexible machined lips. This design minimizes physical engagement with the rotating shaft to reduce friction and heat, allowing for exceptional rotational speeds at the expense of pressure-handling capability.

The fundamental principle behind this seal design is a trade-off: it sacrifices pressure resistance to achieve the lowest possible friction, which is the primary obstacle to performance at high rotational speeds.

Deconstructing the High-Speed Profile

To understand how this seal functions, we must examine its key design characteristics and the environment it requires to operate effectively.

Lightly Loaded, Flexible Lips

The defining feature is a lip design with minimal engagement and light contact force against the shaft. This is a deliberate strategy to reduce the two primary enemies of high-speed sealing: friction and the resulting heat buildup.

Unlike more robust seal profiles, this design does not rely on heavy spring-loading to maintain contact.

The Dual-Lip Design

Most profiles incorporate two lips for distinct functions. A primary main lip provides fluid retention, while a secondary excluder lip is oriented outward to prevent external contaminants like dust and debris from reaching the sealing surface.

Key Operational Parameters

This specific profile is engineered for a very particular operating window. It excels at rotational speeds up to 5,000 surface feet per minute (SFPM).

However, its pressure-handling capability is limited to approximately 50 psi. This is a direct consequence of the lightly loaded lip design.

Strict Shaft Requirements

The seal's effectiveness is highly dependent on the condition of the shaft. It requires minimal shaft runout (wobble) and a smooth surface finish. The flexible, lightly-loaded lip cannot compensate for significant shaft imperfections and will leak if the dynamic runout is too high.

Why PTFE is the Material of Choice

The specific properties of Polytetrafluoroethylene (PTFE) are not just beneficial; they are essential for making this seal design viable. The material's inherent characteristics directly enable high-speed performance.

Exceptionally Low Friction

PTFE has one of the lowest coefficients of friction of any solid material, often compared to wet ice on wet ice. This inherent slipperiness is the single most important property, as it is the foundation for minimizing heat generation at thousands of SFPM.

Wide Temperature Resistance

Even with a low-friction design, high speeds will generate some heat. PTFE’s excellent thermal stability, with a working range up to +260°C (500°F), provides a critical safety margin that prevents material degradation.

Chemical Inertness

PTFE is virtually inert and resistant to almost all industrial chemicals, acids, and solvents. This allows the seal to be used in applications with aggressive media where traditional elastomer seals would quickly fail.

Non-Stick & Hydrophobic Properties

The material’s non-stick and water-repelling (hydrophobic) nature helps prevent the sealed media from adhering to the lip. This ensures a clean, consistent sealing point and prevents buildup that could compromise performance.

Understanding the Trade-offs

Choosing this seal profile involves accepting a specific set of limitations. Its specialization in speed comes at the cost of versatility in other areas.

Severely Limited Pressure Capability

The most significant trade-off is pressure. The design that allows for high speed is precisely what makes it unsuitable for high-pressure applications. A high-pressure PTFE seal profile, by contrast, has a much stiffer, more heavily loaded lip and is limited to slower speeds (around 1,000 SFPM) but can handle pressures up to 3,000 psi.

Sensitivity to Shaft Condition

This seal is less forgiving than its high-pressure counterparts. Any significant shaft runout, vibration, or surface imperfection can easily break the delicate contact of the sealing lip, leading to immediate leakage.

Making the Right Choice for Your Application

Selecting the correct seal profile requires a clear understanding of your primary operational demand.

- If your primary focus is maximizing rotational speed: This low-pressure, lightly loaded profile is specifically engineered for your goal.

- If your primary focus is containing high pressure: You must use a high-pressure seal profile with a more robust, heavily loaded lip design and accept the lower speed limits.

- If your primary focus is chemical compatibility: PTFE is an excellent material choice, but you must still select the specific profile that matches your speed and pressure requirements.

Ultimately, the high-speed, low-pressure PTFE seal is a specialized component, masterfully designed for applications where velocity is the paramount challenge.

Summary Table:

| Characteristic | Description | Key Parameter |

|---|---|---|

| Lip Design | Lightly loaded, flexible lips for minimal friction and heat generation. | Minimal engagement |

| Lip Configuration | Dual-lip design: main lip for fluid retention, excluder lip for debris protection. | Two distinct functions |

| Speed Capability | Engineered for extremely high rotational speeds. | Up to 5,000 SFPM |

| Pressure Limit | Sacrifices pressure resistance for speed. | ~50 psi |

| Shaft Requirements | Requires minimal runout and a smooth surface finish for effective sealing. | Low tolerance for imperfection |

| Material Advantage | PTFE provides low friction, high temperature resistance, and chemical inertness. | Essential for performance |

Need a high-performance PTFE seal for your high-speed application?

At KINTEK, we specialize in precision manufacturing of PTFE components, including custom seals, liners, and labware. Our expertise in custom fabrication—from prototypes to high-volume orders—ensures you get a seal profile perfectly tailored to your speed, pressure, and chemical compatibility requirements.

Let us help you solve your toughest sealing challenges. Contact our engineering team today for a consultation!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance

- What is PTFE commonly known as and what are its unique properties? Unlock Unmatched Chemical & Thermal Resistance

- What are the key benefits of PTFE in custom fabrication? Unlock Performance in Extreme Conditions

- Why is PTFE suitable for cryogenic or high-temperature applications? Unmatched Thermal Stability from -450°F to 500°F