At their core, the benefits of white TFE encapsulated silicone gaskets stem from a hybrid design that combines the chemical purity and non-stick surface of TFE with the flexibility and temperature resistance of a silicone core. This construction makes them exceptionally well-suited for sanitary applications, particularly in the pharmaceutical industry, by providing a reliable seal that is both clean in appearance and operationally versatile.

The key advantage is combining two materials to get the best of both worlds: TFE provides an inert, sanitary product-contact surface, while the silicone core provides the mechanical flexibility and resilience needed to create and maintain a tight seal across a wide range of temperatures.

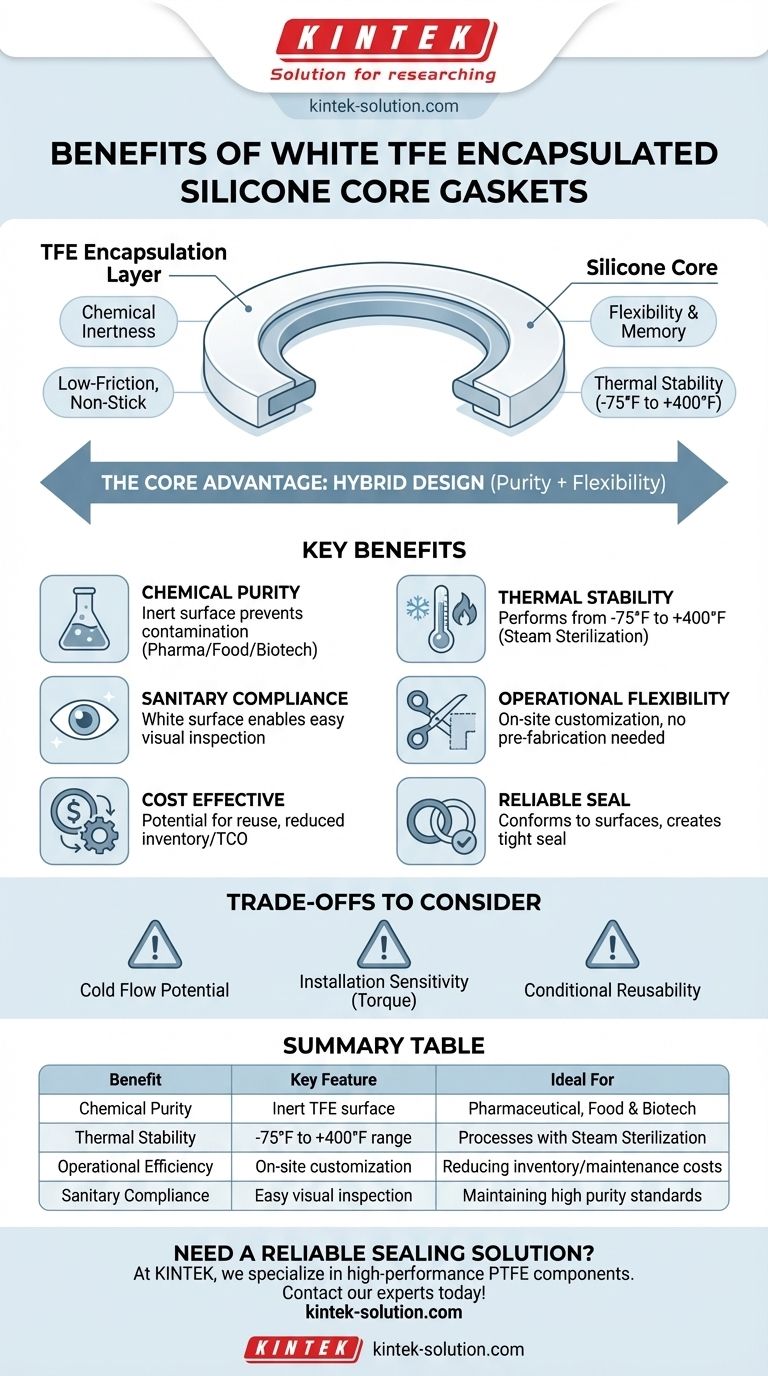

The Core Advantage: A Hybrid Material Design

The unique properties of these gaskets come from their two-part construction. Understanding each component reveals why they are so effective in specific environments.

The TFE Encapsulation Layer

The outer layer is made of TFE (Polytetrafluoroethylene), a fluoropolymer known for its exceptional properties. This layer is the only part of the gasket that comes into contact with the process material.

Its primary benefit is chemical inertness. TFE is resistant to nearly all industrial chemicals and solvents, ensuring that it will not react with or contaminate the product.

This material also provides a low-friction, non-stick surface, which is crucial for preventing material buildup and simplifying cleaning processes.

The Silicone Core

The inner core is made of silicone, a highly resilient elastomer. This core gives the gasket its flexibility and "memory."

The silicone allows the gasket to compress and conform to the sealing surfaces, creating a tight, leak-proof seal even on surfaces with minor imperfections.

Silicone is also responsible for the gasket's impressive thermal stability, allowing it to function effectively in temperatures ranging from -75°F (-60°C) to +400°F (+205°C), accommodating processes like steam sterilization.

The "White" Advantage in Sanitary Applications

The white color is a deliberate design choice for hygienic industries. It provides a clean, sanitary appearance that is preferred in pharmaceutical and food processing environments.

More importantly, the white surface makes visual inspection for cleanliness and integrity simple and effective. Any discoloration or particulate is immediately obvious, which is a critical factor for maintaining purity standards.

Operational and Financial Benefits

Beyond the material science, these gaskets offer practical advantages that impact workflow and budget.

On-Site Customization

A significant benefit is the ability to cut these gaskets to any required shape on-site. This eliminates the need for pre-fabrication and long lead times for custom parts.

This flexibility dramatically reduces procurement complexity and the need to hold a large inventory of specialized, pre-cut gaskets.

Reduced Total Cost of Ownership

The durable nature of the TFE surface and the resilience of the silicone core mean these gaskets can sometimes be reused.

When inspected and deemed fit for another service cycle, reusability can significantly lower the total cost of ownership by reducing consumption and waste.

Understanding the Trade-offs

While highly effective, it is crucial to understand the limitations of this gasket type to ensure proper application.

Potential for Cold Flow

TFE, like other fluoropolymers, can be susceptible to "cold flow" or creep. This is a gradual deformation of the material under sustained pressure, which can lead to a loosening of the seal over time. Regular torque checks are often necessary in critical applications.

Installation Sensitivity

The thin TFE encapsulation layer can be damaged by over-tightening. Excessive force can crack or split the TFE, compromising its inert barrier and leading to seal failure. Proper installation torque is critical.

Conditional Reusability

Reusability is not guaranteed. It is highly dependent on the application's pressure, temperature cycles, and chemical exposure. Each gasket must be carefully inspected for any signs of deformation, discoloration, or damage to the TFE layer before being reused.

Making the Right Choice for Your Application

Selecting the correct gasket requires matching its properties to your primary operational goal.

- If your primary focus is product purity and visual inspection: The inert, non-stick, white TFE surface is ideal for high-purity pharmaceutical, food, and biotech processes.

- If your primary focus is operational flexibility and cost management: The ability to cut gaskets on-site and the potential for reuse offer tangible benefits in reducing inventory and maintenance costs.

- If your primary focus is high pressure or frequent thermal cycling: You must account for TFE's potential for cold flow and ensure proper installation and maintenance procedures are in place.

Ultimately, choosing a white TFE encapsulated silicone gasket is an investment in purity, performance, and operational efficiency for demanding sanitary systems.

Summary Table:

| Benefit | Key Feature | Ideal For |

|---|---|---|

| Chemical Purity | Inert TFE surface prevents contamination | Pharmaceutical, Food & Biotech |

| Thermal Stability | Silicone core performs from -75°F to +400°F | Processes requiring steam sterilization |

| Operational Efficiency | On-site customization & potential reusability | Reducing inventory and maintenance costs |

| Sanitary Compliance | White surface enables easy visual inspection | Maintaining high purity standards |

Need a reliable sealing solution for your sanitary application?

At KINTEK, we specialize in manufacturing high-performance PTFE components, including custom TFE encapsulated gaskets, for the semiconductor, medical, laboratory, and industrial sectors. Our precision production ensures you get the perfect seal for purity-critical processes, from prototypes to high-volume orders.

Let us help you optimize your system's performance and efficiency. Contact our experts today to discuss your specific requirements!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

People Also Ask

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What is PTFE commonly known as and what are its unique properties? Unlock Unmatched Chemical & Thermal Resistance

- What are the key benefits of PTFE in custom fabrication? Unlock Performance in Extreme Conditions

- Why is PTFE suitable for cryogenic or high-temperature applications? Unmatched Thermal Stability from -450°F to 500°F

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance