The primary benefits of using PTFE PCB material are its exceptional electrical performance at high frequencies, outstanding thermal stability, and robust resistance to chemicals and moisture. This unique combination ensures signal integrity and operational reliability in demanding applications where standard materials like FR-4 would fail.

PTFE is not just another PCB substrate; it is a specialized engineering material. Its core value lies in providing predictable, stable performance for high-frequency signals, even when subjected to extreme temperatures, harsh chemicals, or high humidity.

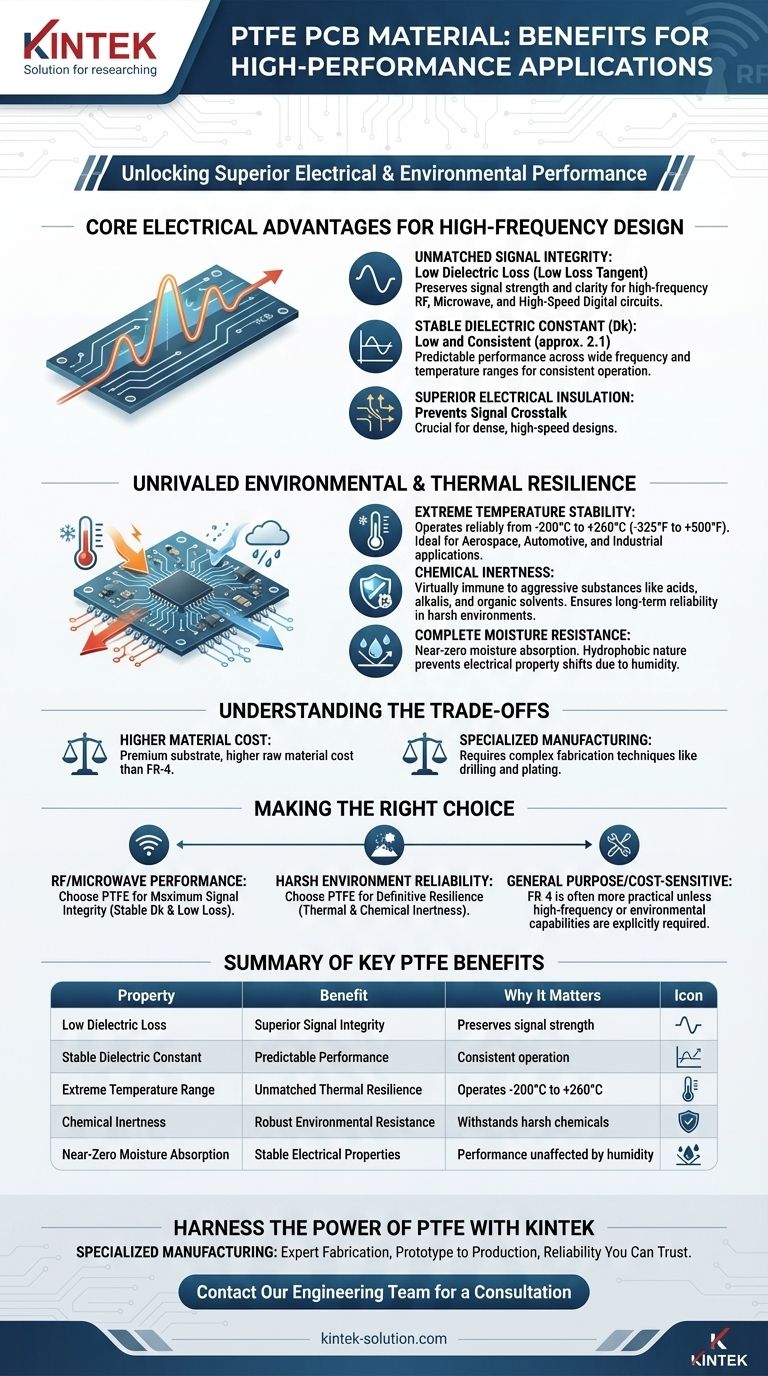

The Core Electrical Advantages for High-Frequency Design

For radio frequency (RF), microwave, and high-speed digital circuits, the electrical properties of the PCB substrate are paramount. PTFE excels in this domain.

Unmatched Signal Integrity

PTFE has an inherently low dielectric loss, also known as a low loss tangent. This means that as an electrical signal travels through the material, less of its energy is absorbed and converted into heat.

This property is critical for preserving the strength and clarity of high-frequency signals, ensuring they reach their destination with minimal degradation.

Stable Dielectric Constant (Dk)

PTFE features a very low and, more importantly, highly stable dielectric constant (Dk) of around 2.1.

While the low value helps maintain signal speed, its stability across a wide range of frequencies and temperatures is the key benefit. This predictability ensures that circuit performance remains consistent whether the device is operating in a cold environment or at peak thermal load.

Superior Electrical Insulation

As an excellent electrical insulator, PTFE effectively prevents signal crosstalk between adjacent traces on a circuit board. This isolation is crucial for dense, high-speed designs where signals can easily interfere with one another.

Unrivaled Environmental and Thermal Resilience

Many high-performance electronics must operate in environments that are hostile to conventional materials. PTFE is engineered to withstand these conditions.

Extreme Temperature Stability

PTFE maintains its structural and electrical integrity across an exceptionally broad temperature range, typically from -200°C to +260°C (-325°F to +500°F).

This resilience makes it an ideal choice for aerospace, automotive, and industrial applications that experience extreme thermal cycling.

Chemical Inertness

The material is virtually immune to chemical attack. It offers superior resistance to aggressive substances, including strong acids, alkalis, and organic solvents.

This inertness guarantees long-term reliability in chemically harsh operational environments, such as in industrial sensors or medical equipment.

Complete Moisture Resistance

PTFE is hydrophobic, meaning it repels water. It has near-zero moisture absorption, which prevents the PCB's electrical properties from changing due to humidity.

This is a significant advantage over materials like FR-4, whose dielectric properties can shift as it absorbs moisture from the air, leading to inconsistent performance.

Understanding the Trade-offs

While PTFE's performance is exceptional, it is a specialized material with practical considerations that are important for any design decision.

Higher Material Cost

PTFE is a premium substrate. Its raw material cost is significantly higher than that of standard materials like FR-4, making it less suitable for cost-sensitive, low-frequency applications.

Specialized Manufacturing Processes

The softness and chemical inertness of PTFE require specialized fabrication techniques. Processes like drilling and plating through-holes are more complex and costly than with traditional rigid boards, which can impact both project timelines and budget.

Making the Right Choice for Your Application

Selecting the right PCB material requires balancing performance needs with practical constraints.

- If your primary focus is RF/Microwave Performance: PTFE is the superior choice due to its stable dielectric constant and low signal loss, ensuring maximum signal integrity.

- If your primary focus is Harsh Environment Reliability: PTFE's unmatched thermal stability and chemical inertness make it the definitive material for applications where failure is not an option.

- If your primary focus is General Purpose or Cost-Sensitive Design: A standard material like FR-4 is often more practical unless your design explicitly requires PTFE's high-frequency or environmental capabilities.

By understanding these core benefits and trade-offs, you can confidently specify PTFE for applications where performance and reliability are paramount.

Summary Table:

| Property | Benefit | Why It Matters |

|---|---|---|

| Low Dielectric Loss | Superior Signal Integrity | Preserves signal strength in RF/microwave circuits |

| Stable Dielectric Constant | Predictable Performance | Ensures consistent operation across frequencies & temperatures |

| Extreme Temperature Range | Unmatched Thermal Resilience | Operates reliably from -200°C to +260°C |

| Chemical Inertness | Robust Environmental Resistance | Withstands harsh chemicals, acids, and solvents |

| Near-Zero Moisture Absorption | Stable Electrical Properties | Performance unaffected by humidity or moisture |

Ready to harness the power of PTFE for your next high-performance project?

KINTEK specializes in the precision manufacturing of high-quality PTFE components, including custom seals, liners, and labware. We understand the critical demands of semiconductor, medical, laboratory, and industrial applications.

We offer:

- Expert Fabrication: Navigating the complexities of working with PTFE to deliver components that meet your exact specifications.

- Prototype to Production: Seamless support from initial concept through to high-volume manufacturing.

- Reliability You Can Trust: Components engineered for superior performance in the most demanding environments.

Let's discuss how our PTFE solutions can enhance your product's reliability and performance.

Contact our engineering team today for a consultation.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support