The primary benefits of using PTFE in ball valve seats and Y strainer seals are its exceptional chemical resistance, extremely low friction, and wide temperature tolerance. These properties result in a highly durable and reliable seal that minimizes operational wear and prevents leaks across a vast range of industrial applications, from chemical processing to food and beverage production.

The core reason PTFE dominates these applications is its unique molecular structure. It creates a material that is simultaneously chemically inert, incredibly slick, and dimensionally stable, directly solving the fundamental challenges of creating a long-lasting, leak-proof seal in a dynamic system.

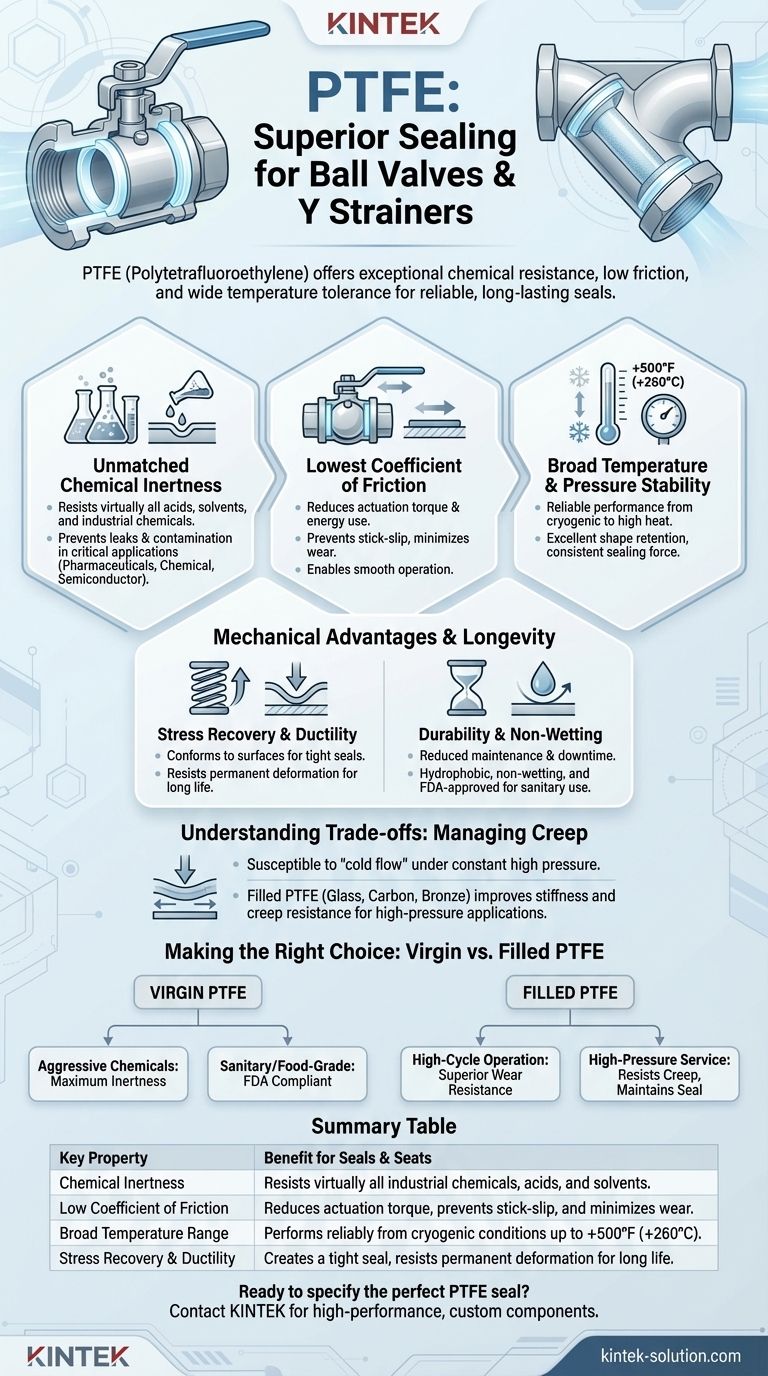

Why PTFE is a Superior Sealing Material

To understand the value of PTFE (Polytetrafluoroethylene), we must look beyond a simple list of features and examine how its core properties translate into real-world performance within a valve or strainer.

Unmatched Chemical Inertness

PTFE is virtually inert to almost all industrial chemicals, acids, and solvents. This makes it the default choice for systems handling aggressive media where other elastomers or plastics would quickly degrade and fail.

This level of resistance ensures the seal maintains its integrity, preventing dangerous leaks and contamination in sensitive industries like pharmaceuticals, chemical manufacturing, and semiconductor production.

The Lowest Coefficient of Friction

PTFE has the lowest coefficient of friction of any solid material. This "slipperiness" is critical for components like ball valve seats, which must allow a ball to rotate smoothly against them thousands of times.

This property reduces the torque required to actuate the valve, allowing for smaller, more energy-efficient actuators. It also prevents stick-slip behavior—the jerky motion that can cause wear and inconsistent sealing—and means the seal can often function without any external lubrication.

Broad Temperature and Pressure Stability

PTFE seals perform reliably across an exceptionally wide temperature range, maintaining their properties from cryogenic conditions up to +500°F (+260°C).

They also demonstrate excellent shape retention, with low thermal expansion coefficients. This means the seal will not drastically change size with temperature fluctuations, ensuring a consistent and reliable sealing force.

The Mechanical Advantages for Valves and Strainers

Beyond its fundamental chemical and thermal properties, PTFE's mechanical characteristics make it an ideal engineering material for sealing.

Excellent Stress Recovery and Ductility

A sealing material must be able to deform to create a tight seal and then recover its shape. PTFE has sufficient ductility to conform to minor imperfections on sealing surfaces, creating a leak-proof barrier.

Furthermore, it exhibits good stress recovery, meaning it resists permanent deformation (compression set) under load, ensuring it continues to provide sealing pressure over a long service life.

Durability and Long Service Life

The combination of chemical resistance, low wear, and dimensional stability gives PTFE seals exceptional longevity. This directly translates to reduced maintenance schedules, less downtime, and lower operating costs over the life of the equipment.

Hydrophobic and Non-Wetting Properties

PTFE is hydrophobic (repels water) and non-wetting. This prevents media from adhering to the seal surface, which is crucial for ease of cleaning and preventing residue buildup. This characteristic, combined with its inertness, is why PTFE is widely FDA-approved for sanitary applications.

Understanding the Trade-offs

While PTFE is an outstanding material, it is not without limitations. Understanding these is key to proper application.

Susceptibility to Creep

Standard PTFE can be prone to creep, or "cold flow," where the material slowly deforms under a constant, high-pressure mechanical load. This can be a concern in high-pressure static sealing applications.

Managing Mechanical Limitations

To overcome this and other mechanical limitations, PTFE is often blended with fillers like glass, carbon, or bronze. These fillers significantly improve wear resistance, stiffness, and resistance to creep.

However, adding fillers can sometimes reduce the overall chemical resistance or increase the coefficient of friction slightly. The specific grade of PTFE must be matched to the precise demands of the application.

Making the Right Choice for Your Application

Selecting PTFE is often the first step, but choosing the correct grade is what ensures optimal performance.

- If your primary focus is aggressive chemicals: Virgin (unfilled) PTFE is the safest choice due to its maximum chemical inertness.

- If your primary focus is high-cycle valve operation: A filled grade of PTFE (e.g., carbon-filled) will provide superior wear resistance and a longer service life.

- If your primary focus is sanitary or food-grade systems: Virgin PTFE is essential for its FDA compliance and non-contaminating properties.

- If your primary focus is high-pressure service: A spring-energized or filled PTFE seal will offer the necessary resistance to creep and maintain sealing force.

By understanding these core properties and trade-offs, you can confidently specify PTFE for applications that demand the highest levels of reliability and performance.

Summary Table:

| Key Property | Benefit for Seals & Seats |

|---|---|

| Chemical Inertness | Resists virtually all industrial chemicals, acids, and solvents. |

| Low Coefficient of Friction | Reduces actuation torque, prevents stick-slip, and minimizes wear. |

| Broad Temperature Range | Performs reliably from cryogenic conditions up to +500°F (+260°C). |

| Stress Recovery & Ductility | Creates a tight seal, resists permanent deformation for long life. |

Ready to specify the perfect PTFE seal for your application?

At KINTEK, we specialize in manufacturing high-performance PTFE components—including custom ball valve seats and Y strainer seals—for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in precision production and custom fabrication ensures you get a solution tailored to your specific chemical, temperature, and pressure requirements, from prototypes to high-volume orders.

Contact our experts today to discuss your project and discover how our PTFE components can enhance your system's reliability and longevity.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE and Nitrile Diaphragm Pump Components for Demanding Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What are the key benefits of PTFE in custom fabrication? Unlock Performance in Extreme Conditions

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What are the primary applications of PTFE fasteners and custom parts? Critical Solutions for Extreme Environments

- Why is PTFE suitable for cryogenic or high-temperature applications? Unmatched Thermal Stability from -450°F to 500°F

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance