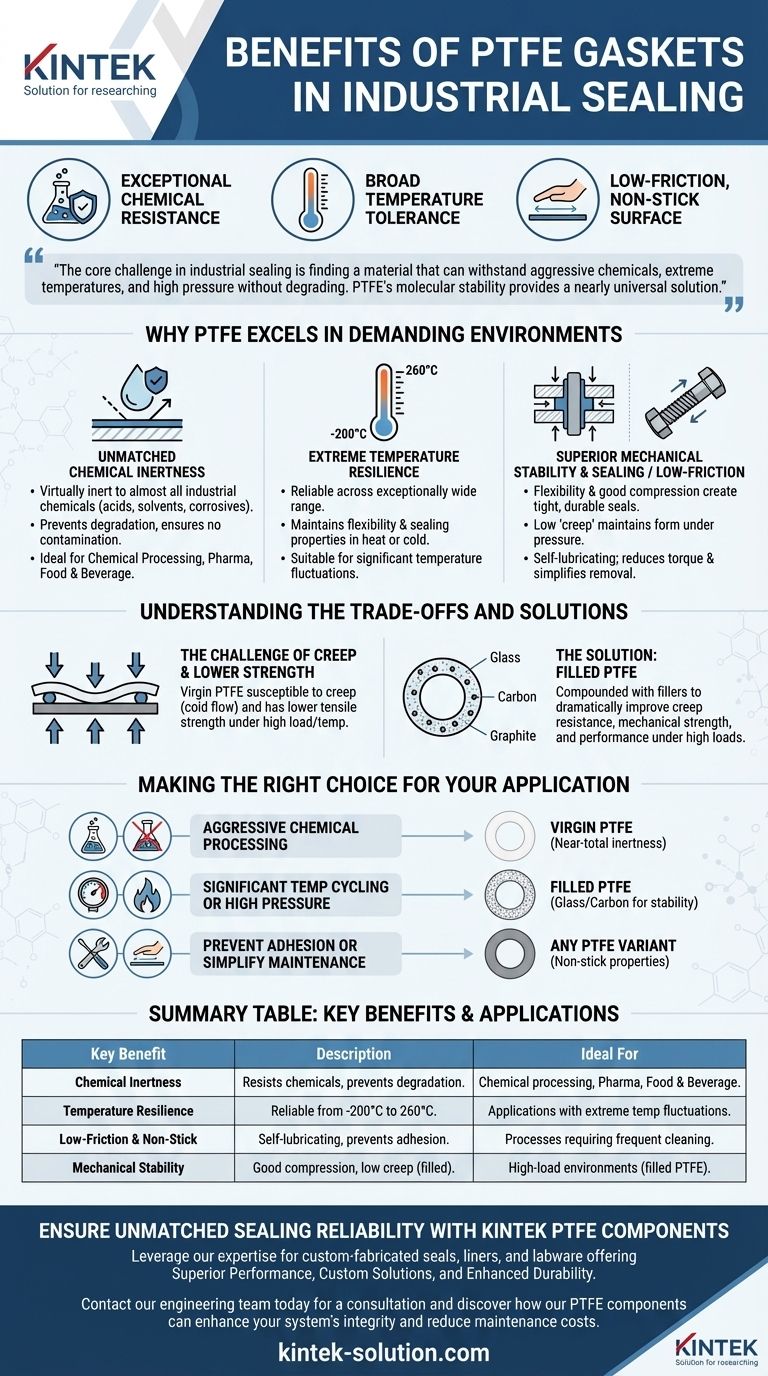

The primary benefits of PTFE gaskets are their exceptional chemical resistance, broad temperature tolerance, and low-friction, non-stick surface. This unique combination makes them a highly reliable sealing solution for demanding industrial applications, preventing leaks and reducing maintenance in environments where other materials would quickly fail.

The core challenge in industrial sealing is finding a material that can withstand aggressive chemicals, extreme temperatures, and high pressure without degrading. PTFE's molecular stability provides a nearly universal solution, ensuring operational integrity and safety across a vast range of processes.

Why PTFE Excels in Demanding Environments

Polytetrafluoroethylene (PTFE) is not just one material but a family of materials engineered for performance. Its properties directly address the most common points of failure in industrial seals.

Unmatched Chemical Inertness

PTFE is virtually inert to almost all industrial chemicals, including aggressive acids, solvents, and corrosive agents. This prevents material degradation and ensures the gasket will not contaminate the process medium.

This property is critical in industries like chemical processing, pharmaceuticals, and food and beverage, where seal integrity and purity are paramount.

Extreme Temperature Resilience

PTFE gaskets perform reliably across an exceptionally wide temperature range, from cryogenic conditions (-200°C) up to high-heat applications (260°C).

Unlike many elastomers that become brittle in the cold or degrade in heat, PTFE maintains its flexibility and sealing properties, making it suitable for processes with significant temperature fluctuations.

Superior Mechanical Stability and Sealing

A key function of a gasket is to fill imperfections between flange surfaces. PTFE's flexibility and good compression characteristics allow it to conform to these surfaces, creating a tight and durable seal.

It exhibits minimal deformation under load, a property often referred to as low "creep." This ensures it maintains its form under pressure, preventing leaks long after initial installation.

Low-Friction, Non-Stick Surface

PTFE has one of the lowest coefficients of friction of any solid material, often compared to wet ice on wet ice. This self-lubricating property reduces the torque needed to tighten bolts during installation.

Furthermore, its non-stick nature prevents the gasket from adhering to flange surfaces, which simplifies removal and replacement during maintenance, saving time and preventing damage to equipment.

Understanding the Trade-offs and Solutions

While highly effective, it is crucial to understand the limitations of virgin (unfilled) PTFE to ensure proper application and avoid failure.

The Challenge of Creep (Cold Flow)

Under sustained compressive load, especially at elevated temperatures, pure PTFE can be susceptible to creep, also known as cold flow. This is a slow deformation that can eventually lead to a loss of sealing pressure and potential leaks.

Lower Mechanical Strength

Compared to metallic or semi-metallic gaskets, PTFE is a softer material with lower tensile strength. This makes it less suitable for extremely high-pressure applications without reinforcement.

The Solution: Filled PTFE

To counteract these limitations, PTFE is often compounded with filler materials. This creates a range of "filled PTFE" gaskets with enhanced properties.

Common fillers like glass, carbon, or graphite dramatically improve the material's resistance to creep, increase its mechanical strength, and enhance its performance under high loads and temperatures.

Making the Right Choice for Your Application

Selecting the correct gasket material is a critical engineering decision. PTFE offers a versatile platform, but the specific type should align with your operational goals.

- If your primary focus is aggressive chemical processing: Virgin PTFE is often the ideal choice due to its near-total chemical inertness.

- If your application involves significant temperature cycling or high pressure: A filled PTFE, such as one with glass or carbon, will provide the necessary mechanical stability and creep resistance.

- If you need to prevent product adhesion or simplify maintenance: The non-stick properties of any PTFE variant will reduce downtime and protect equipment surfaces.

By understanding its fundamental properties and engineered variations, you can confidently leverage PTFE to ensure a safe, reliable, and efficient seal.

Summary Table:

| Key Benefit | Description | Ideal For |

|---|---|---|

| Chemical Inertness | Resists virtually all industrial chemicals, preventing degradation and contamination. | Chemical processing, pharmaceuticals, food & beverage. |

| Temperature Resilience | Performs reliably from -200°C to 260°C, maintaining flexibility and seal integrity. | Applications with extreme temperature fluctuations. |

| Low-Friction & Non-Stick | Self-lubricating surface simplifies installation and prevents adhesion for easy maintenance. | Processes requiring frequent cleaning or gasket replacement. |

| Mechanical Stability | Good compression and low creep maintain a tight seal under sustained pressure (enhanced with fillers). | High-load environments when using filled PTFE compounds. |

Ensure Unmatched Sealing Reliability with KINTEK PTFE Components

Leverage our expertise in precision PTFE manufacturing to solve your toughest sealing challenges. Whether you're in the semiconductor, medical, laboratory, or industrial sector, KINTEK delivers custom-fabricated PTFE seals, liners, and labware that offer:

- Superior Performance: Benefit from PTFE's exceptional chemical resistance and temperature tolerance.

- Custom Solutions: From prototypes to high-volume orders, we tailor components to your exact specifications.

- Enhanced Durability: Our filled PTFE options provide increased mechanical strength and creep resistance for demanding applications.

Don't let sealing failures compromise your operations. Contact our engineering team today for a consultation and discover how our PTFE components can enhance your system's integrity and reduce maintenance costs.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech