In industrial sealing applications, graphite packing is prized for its exceptional durability and performance under extreme conditions. It is a robust sealing solution known for its high-temperature tolerance, self-lubricating properties, and chemical resistance, making it a go-to choice for demanding pump and valve services.

While many materials provide a reliable seal, graphite packing's unique combination of high-temperature resistance and high thermal conductivity sets it apart. It is the definitive choice for applications where dissipating heat is just as critical as preventing leaks.

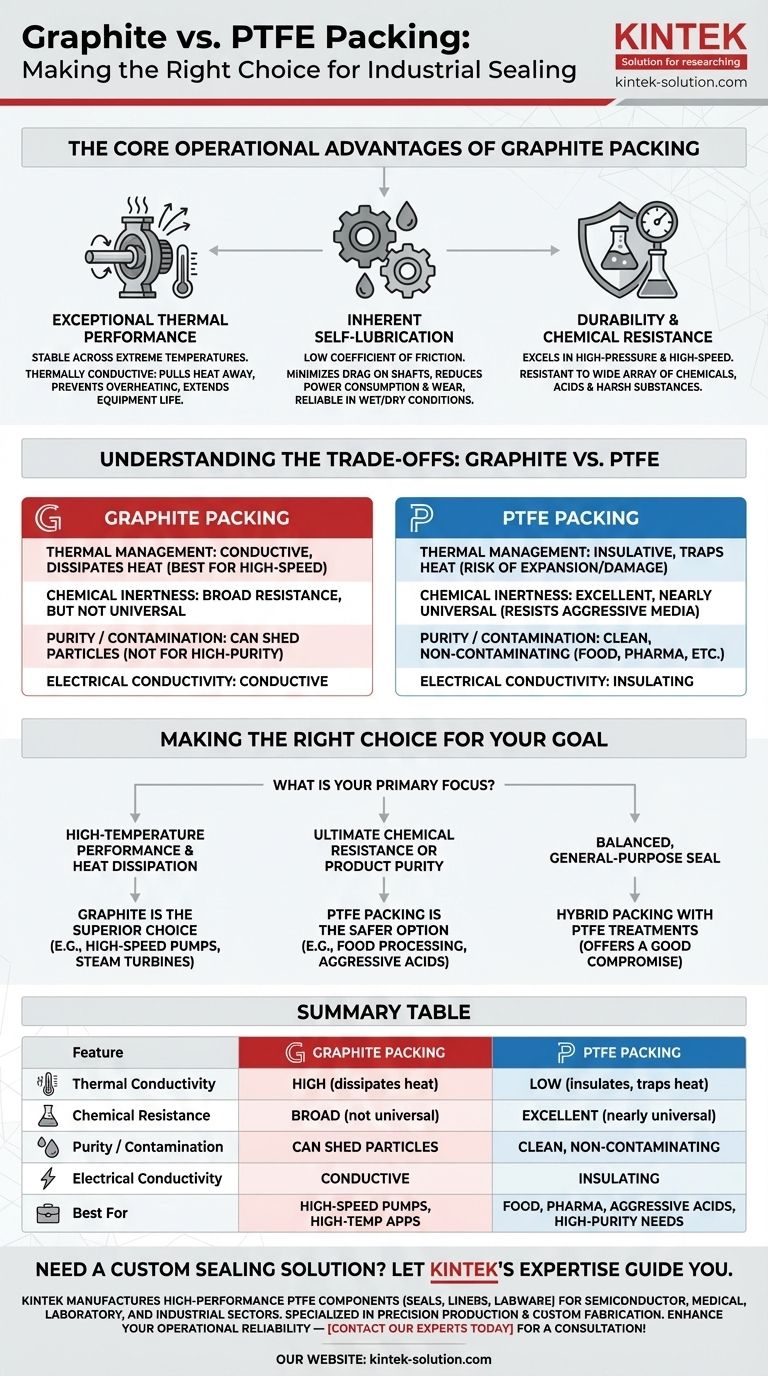

The Core Operational Advantages of Graphite Packing

Graphite packing is engineered from high-quality graphite yarns, which are a pure, inorganic form of carbon. This composition gives it a unique set of properties highly valued in industrial maintenance and engineering.

Exceptional Thermal Performance

Graphite is stable across an extremely wide temperature range, far exceeding that of many synthetic packings.

More importantly, it is thermally conductive. This allows it to pull heat away from the rotating shaft, preventing overheating, reducing wear, and extending the service life of both the packing and the equipment.

Inherent Self-Lubrication

Graphite has a very low coefficient of friction. This natural lubricity minimizes drag on pump shafts and valve stems.

The direct benefits are reduced power consumption for the equipment and less wear on critical components, especially in high-speed shaft applications. It performs reliably in both wet and dry conditions without scoring the shaft.

Durability in Demanding Environments

This packing material excels in high-pressure and high-speed applications where other materials might fail.

It is also resistant to a wide array of chemicals, acids, and harsh substances, making it suitable for chemical processing and other aggressive industrial environments.

Simplified Maintenance and Cost-Effectiveness

Graphite packing is generally straightforward to install and remove, which helps streamline maintenance schedules. It has long been considered a reliable and cost-effective upgrade from older materials like asbestos.

Understanding the Trade-offs: Graphite vs. PTFE

Choosing a packing material requires understanding its limitations. The most common alternative to graphite is PTFE (polytetrafluoroethylene), and comparing them reveals the specific strengths of each.

Thermal Management

This is the most critical distinction. Graphite is thermally conductive and dissipates heat. PTFE is a thermal insulator and traps heat.

In a high-speed pump, the heat trapped by PTFE packing can cause it to expand and damage the shaft. Graphite's ability to conduct heat away makes it the superior choice for high-speed rotating equipment.

Chemical Inertness

PTFE is one of the most chemically inert substances known. It is resistant to nearly all solvents, acids, and bases, making it the only choice for sealing extremely aggressive media like concentrated nitric or sulfuric acid.

While graphite has broad chemical resistance, it is not as universally inert as PTFE.

Purity and Contamination

Graphite packing is made of carbon and can potentially shed fine black particles. This "color pollution" makes it unsuitable for applications where product purity is paramount, such as food, pharmaceutical, or fine chemical production.

PTFE is a clean, non-contaminating material and is the standard for these sanitary or high-purity applications.

Electrical Conductivity

Graphite is electrically conductive, while PTFE is an excellent electrical insulator. This is a critical design consideration where stray currents or galvanic corrosion are a concern, making PTFE the safer choice in those specific scenarios.

Making the Right Choice for Your Goal

Your selection should be driven by the specific demands of the application, not by a single "best" material.

- If your primary focus is high-temperature performance and heat dissipation (e.g., high-speed pumps, steam turbines): Graphite is the superior choice due to its unmatched thermal conductivity.

- If your primary focus is ultimate chemical resistance or product purity (e.g., food processing, aggressive acid handling): PTFE packing is the safer and more reliable option.

- If your primary focus is a balanced, general-purpose seal for moderate conditions: A hybrid packing treated with PTFE can offer a good compromise of graphite's durability and PTFE's clean properties.

By understanding these fundamental trade-offs, you can select a sealing solution that enhances both performance and operational reliability.

Summary Table:

| Feature | Graphite Packing | PTFE Packing |

|---|---|---|

| Thermal Conductivity | High (dissipates heat) | Low (insulates, traps heat) |

| Chemical Resistance | Broad, but not universal | Excellent, nearly universal |

| Purity / Contamination | Can shed particles (not for high-purity) | Clean, non-contaminating |

| Electrical Conductivity | Conductive | Insulating |

| Best For | High-speed pumps, high-temperature applications | Food, pharma, aggressive acids, high-purity needs |

Need a Custom Sealing Solution? Let KINTEK's Expertise Guide You.

Choosing between graphite, PTFE, or a hybrid material is critical for your equipment's performance and longevity. KINTEK manufactures high-performance PTFE components (seals, liners, labware, and more) for the semiconductor, medical, laboratory, and industrial sectors.

We specialize in precision production and custom fabrication, from prototypes to high-volume orders, ensuring you get the exact seal for your specific temperature, chemical, and purity requirements.

Enhance your operational reliability — contact our experts today for a consultation!

Visual Guide

Related Products

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the key steps for properly installing PTFE seals? Ensure a Leak-Free, Long-Lasting Seal

- How do PTFE seals perform under pressurized conditions? Achieving Reliable Sealing in Demanding Environments

- How do FEP and PTFE encapsulated O-rings contribute to equipment longevity? Prevent Costly Downtime with Superior Seals

- What are the benefits of using PTFE seals in demanding industries? Solve Extreme Sealing Challenges

- What are the key properties of PTFE that make it suitable for sealing applications? | High-Performance Seals for Extreme Conditions