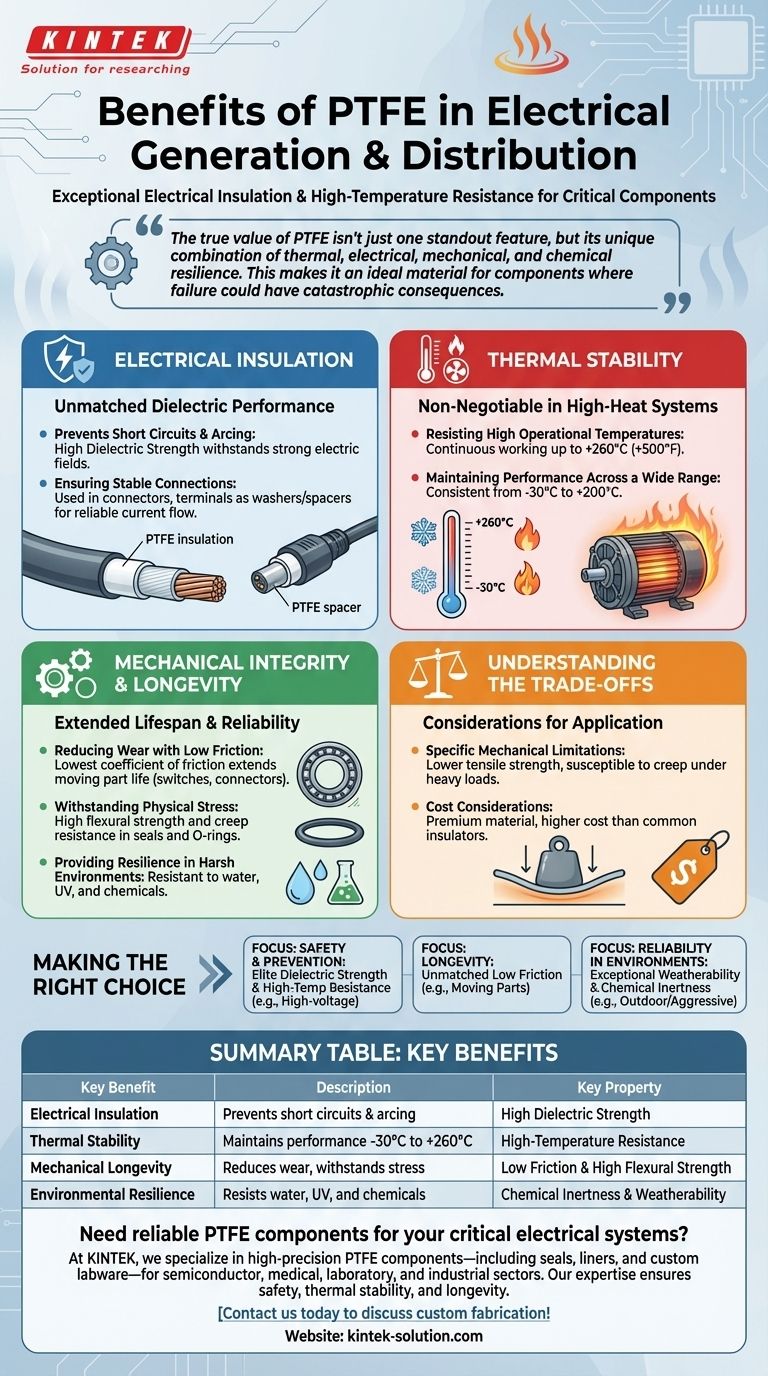

The primary benefits of PTFE in electrical generation and distribution are its exceptional electrical insulation and high-temperature resistance. These two properties work in tandem to ensure the safety, reliability, and longevity of critical components in high-stress electrical environments, preventing short circuits and component failure from operational heat.

The true value of PTFE isn't just one standout feature, but its unique combination of thermal, electrical, mechanical, and chemical resilience. This makes it an ideal material for components where failure could have catastrophic consequences.

The Core Benefit: Unmatched Electrical Insulation

The most fundamental reason for using Polytetrafluoroethylene (PTFE) in the electrical industry is its performance as a dielectric material. It is one of the best insulators known.

Preventing Short Circuits and Arcing

PTFE has a very high dielectric strength, meaning it can withstand a strong electric field without breaking down. This is critical for insulating wires, terminals, and connectors, effectively preventing dangerous short circuits and electrical arcing in high-voltage equipment.

Ensuring Stable Connections

In components like connectors and terminals, PTFE is often used as a washer or spacer. Its insulating properties ensure that electrical current flows only where intended, providing a stable and reliable connection.

Why Thermal Stability is Non-Negotiable

Electrical generation and distribution systems inherently produce significant heat. Materials used within these systems must be able to perform reliably without degrading under thermal stress.

Resisting High Operational Temperatures

PTFE can withstand continuous working temperatures up to +260°C (+500°F). This allows it to maintain its structural and insulating integrity even when in close proximity to conductors carrying high currents.

Maintaining Performance Across a Wide Range

Beyond just high heat, PTFE performs consistently across a broad temperature spectrum, from -30°C to +200°C (-22°F to +392°F). This makes it suitable for equipment that operates in diverse climates, from cold-weather substations to hot-running generators.

Ensuring Mechanical Integrity and Longevity

Beyond its electrical and thermal properties, PTFE's physical characteristics contribute directly to the lifespan and reliability of the components it's made from.

Reducing Wear with Low Friction

PTFE has the lowest coefficient of friction of any solid material. In applications with moving parts, such as switches or rotating connectors, this property dramatically reduces wear and tear, extending the component's operational life.

Withstanding Physical Stress

Components like seals and O-rings must maintain their shape under pressure to prevent leaks and contamination. PTFE's high flexural strength and creep resistance ensure it provides a reliable, long-lasting seal in demanding applications.

Providing Resilience in Harsh Environments

Electrical infrastructure is often exposed to the elements. PTFE is highly resistant to water, UV radiation (weatherability), and is chemically inert to almost all industrial chemicals, ensuring it will not degrade from environmental exposure.

Understanding the Trade-offs

While PTFE's benefits are significant, no material is perfect for every application. Its primary trade-offs are its relative softness and higher cost compared to more common insulators.

Specific Mechanical Limitations

Compared to some hard engineering plastics, PTFE has lower tensile strength and can be susceptible to "creep" (slow deformation) under a sustained heavy load. For applications requiring extreme structural rigidity, a different or composite material may be necessary.

Cost Considerations

PTFE is a premium performance material and is generally more expensive than common insulators like PVC or polyethylene. Its use is typically justified in critical applications where its unique combination of properties is required to ensure safety and long-term reliability.

Making the Right Choice for Your Application

To leverage PTFE effectively, align its specific strengths with your primary engineering goal.

- If your primary focus is safety and failure prevention in high-voltage components: PTFE's elite dielectric strength and high-temperature resistance are its most valuable assets.

- If your primary focus is longevity for moving parts like switches or connectors: Prioritize its unmatched low coefficient of friction to minimize mechanical wear.

- If your primary focus is reliability in outdoor or chemically aggressive environments: Leverage its exceptional weatherability, water resistance, and chemical inertness to prevent material degradation.

Ultimately, choosing PTFE is an investment in unparalleled operational reliability for your most critical electrical components.

Summary Table:

| Key Benefit | Description | Key Property |

|---|---|---|

| Electrical Insulation | Prevents short circuits & arcing in high-voltage equipment. | High Dielectric Strength |

| Thermal Stability | Maintains performance from -30°C to +260°C. | High-Temperature Resistance |

| Mechanical Longevity | Reduces wear in moving parts and withstands physical stress. | Low Friction & High Flexural Strength |

| Environmental Resilience | Resists water, UV, and chemicals for outdoor/industrial use. | Chemical Inertness & Weatherability |

Need reliable PTFE components for your critical electrical systems?

At KINTEK, we specialize in manufacturing high-precision PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures your components deliver the safety, thermal stability, and longevity your applications demand.

Contact us today to discuss custom fabrication from prototypes to high-volume orders!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs