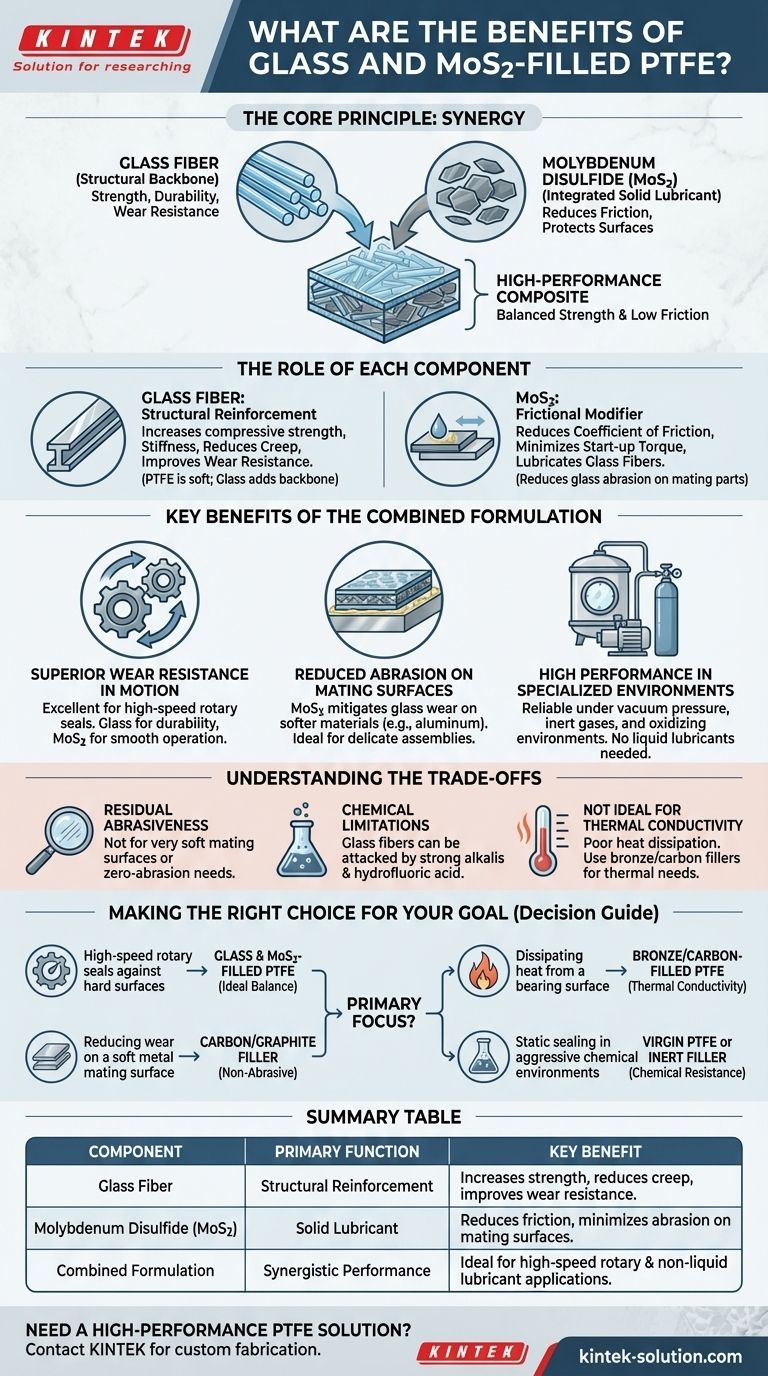

To put it directly, combining glass fiber and molybdenum disulfide (MoS2) in PTFE creates a high-performance composite material. This blend capitalizes on the strength and wear resistance of glass while using the lubricating properties of MoS2 to reduce friction and minimize the abrasiveness of the glass itself. The result is a material uniquely suited for demanding, dynamic applications.

The core principle is synergy: glass provides the structural backbone for strength and durability, while MoS2 acts as an integrated solid lubricant, enhancing performance in motion and protecting mating surfaces.

The Role of Each Component

To understand the benefits of the compound, we must first understand the function of each filler. They are not added arbitrarily; each solves a specific weakness of unfilled, or "virgin," PTFE.

Glass Fiber: The Structural Reinforcement

Virgin PTFE is an exceptionally slick and chemically inert material, but it is also soft and prone to "cold flow," or deformation under load.

Glass fiber is added to counteract this. It dramatically improves the mechanical properties of PTFE, providing enhanced compressive strength and stiffness.

This structural reinforcement significantly reduces creep and improves wear resistance, making the material far more durable in mechanical applications. Glass-filled PTFE is also an excellent electrical insulator.

Molybdenum Disulfide (MoS2): The Frictional Modifier

While glass adds strength, it can also increase friction and be abrasive to softer metal surfaces. This is where Molybdenum Disulfide (MoS2) comes in.

MoS2 is a dry lubricant. When blended into the PTFE and glass matrix, it makes the material harder and significantly more slippery.

This addition reduces the coefficient of friction and minimizes the torque required on start-up in rotating applications. Crucially, it lubricates the glass fibers, reducing their abrasive effect on other parts.

Key Benefits of the Combined Formulation

The true value of this material emerges from the interaction between the two fillers. It creates a balanced compound that outperforms materials with just a single filler in specific scenarios.

Superior Wear Resistance in Motion

The combination offers excellent wear resistance for high-speed and rotary applications. The glass provides the raw durability, while the MoS2 ensures smooth, low-friction operation that prevents premature failure.

Reduced Abrasion on Mating Surfaces

This is the compound's most critical advantage. While a standard glass-filled PTFE can quickly wear down softer mating surfaces like aluminum, the lubricating effect of MoS2 mitigates this wear. It allows for the use of a strong composite without damaging the larger assembly.

High Performance in Specialized Environments

This specific formulation excels in applications where liquid lubricants are not an option. It performs reliably under vacuum pressure, in the presence of inert gases, or in many oxidizing environments.

Understanding the Trade-offs

No material is perfect for every situation. Objectivity requires acknowledging the limitations of even a high-performance compound like this.

Residual Abrasiveness

While MoS2 significantly reduces the abrasiveness of the glass fibers, it does not eliminate it entirely. For applications involving very soft mating surfaces or where zero abrasion is tolerated, a different filler like carbon or graphite may be a better choice.

Chemical Limitations

While PTFE itself is nearly chemically inert, glass fibers are not. They can be attacked by strong alkaline solutions and hydrofluoric acid. This makes the compound unsuitable for a narrow but critical range of chemical applications.

Not Ideal for Thermal Conductivity

The primary purpose of this blend is mechanical performance and low friction. If your application requires dissipating heat, a bronze-filled or carbon-filled PTFE would be a far more effective choice, as those fillers improve thermal conductivity.

Making the Right Choice for Your Goal

Selecting the correct filled PTFE depends entirely on the primary demands of your application. Use this as a guide to your decision.

- If your primary focus is high-speed rotary seals against hard surfaces: Glass and MoS2-filled PTFE is an ideal candidate, offering a superb balance of wear resistance and low friction.

- If your primary focus is reducing wear on a soft metal mating surface: A non-abrasive filler like carbon/graphite should be considered first, as even this mitigated compound may cause unacceptable wear.

- If your primary focus is dissipating heat from a bearing surface: A bronze-filled or carbon-filled PTFE is the technically superior choice due to its higher thermal conductivity.

- If your primary focus is static sealing in aggressive chemical environments: Virgin PTFE or a formulation with a more inert filler may be required, especially if strong alkalis are present.

Ultimately, choosing the right material is about matching its specific, engineered properties to the unique challenges of your design.

Summary Table:

| Component | Primary Function | Key Benefit |

|---|---|---|

| Glass Fiber | Structural Reinforcement | Increases compressive strength, reduces creep, improves wear resistance. |

| Molybdenum Disulfide (MoS2) | Solid Lubricant | Reduces coefficient of friction and minimizes abrasion on mating surfaces. |

| Combined Formulation | Synergistic Performance | Ideal for high-speed rotary seals and applications where liquid lubricants can't be used. |

Need a high-performance PTFE solution for your demanding application?

At KINTEK, we specialize in manufacturing precision PTFE components, including custom glass and MoS2-filled formulations. Whether you're in the semiconductor, medical, laboratory, or industrial sector, our expertise in custom fabrication—from prototypes to high-volume orders—ensures you get the exact material properties your design requires.

Let's discuss how our PTFE composites can enhance your product's durability and performance. Contact our experts today for a consultation!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Teflon Parts Manufacturer Conductive Glass Substrate Cleaning Rack

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability