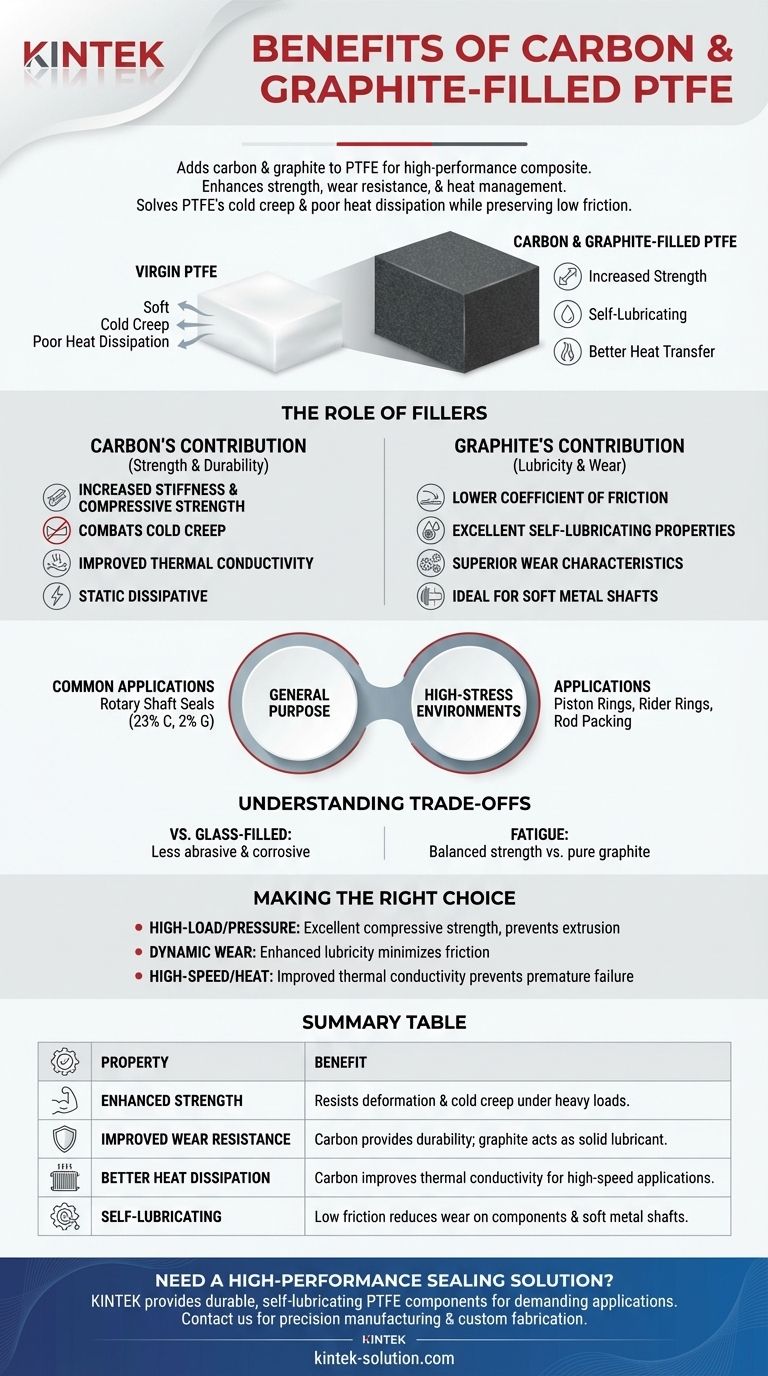

In short, adding carbon and graphite to PTFE creates a high-performance composite material that significantly enhances its mechanical strength, resistance to wear and deformation, and its ability to manage heat. The carbon provides structural integrity and wear resistance, while the graphite acts as a solid lubricant, creating a material ideal for demanding sealing and bearing applications.

The core benefit of carbon and graphite-filled PTFE is that it solves the primary weaknesses of virgin PTFE—its tendency to deform under load (cold creep) and its poor heat dissipation—while preserving its famously low friction. This creates a robust, self-lubricating material for high-stress industrial environments.

The Role of Fillers: Enhancing Core PTFE Properties

Virgin PTFE is an exceptional material known for its chemical inertness and low friction, but it is mechanically soft. Fillers like carbon and graphite are added to create a composite that elevates its performance for dynamic and high-load applications.

Carbon's Contribution: Strength and Durability

Carbon, added as a powder or fiber, is primarily responsible for improving the material's mechanical and thermal properties.

It provides a significant increase in compressive strength and stiffness, making the material far more resistant to deformation under heavy loads.

This structural enhancement directly combats cold creep, the tendency of virgin PTFE to slowly deform over time when a load is applied.

Carbon also improves thermal conductivity, allowing the material to dissipate heat generated from friction more effectively. This is critical in high-speed applications.

Furthermore, carbon's electrical conductivity makes the composite static dissipative, a necessary property in environments where static buildup is a concern.

Graphite's Contribution: Lubricity and Wear

Graphite is one of the best solid lubricants available. Its addition to the PTFE blend serves a very specific purpose.

It dramatically lowers the coefficient of friction, enhancing the material's natural slipperiness and reducing breakaway torque.

This results in excellent self-lubricating properties, which is crucial for improving wear resistance, especially when paired with softer metal shafts that could otherwise be damaged by more abrasive fillers.

The combination of carbon and graphite provides superior wear characteristics compared to using either filler alone.

Common Applications and Formulations

The synergy between carbon's strength and graphite's lubricity makes this blend a go-to choice for several critical industrial components.

A General-Purpose Workhorse

A common formulation of 23% carbon and 2% graphite is widely recognized as an excellent general-purpose material for applications like rotary shaft seals.

High-Stress Environments

This blend is ideally suited for components in industrial compressors, including piston rings, rider rings, and rod packing.

These applications demand resistance to high pressures and temperatures, where resistance to extrusion and deformation is non-negotiable.

Understanding the Trade-offs

While carbon and graphite-filled PTFE is a superior material for many uses, it's important to understand its context and limitations.

Performance vs. Other Fillers

Compared to glass-filled PTFE, the carbon and graphite blend is less abrasive and corrosive. This makes it the preferred choice for applications involving soft metals like aluminum or stainless steel shafts.

Fatigue Resistance

While carbon provides excellent mechanical strength, pure graphite-filled PTFE can have lower fatigue resistance than a carbon-only blend. The combination leverages the strengths of both to create a balanced material.

Chemical Compatibility

While PTFE itself is nearly inert, the addition of carbon can slightly reduce its chemical resistance in highly oxidative environments. This is a minor trade-off that is irrelevant for the vast majority of applications.

Making the Right Choice for Your Application

Selecting the correct material requires aligning its properties with your primary operational goal.

- If your primary focus is high-load or high-pressure sealing: The blend's excellent compressive strength and resistance to cold creep make it the ideal choice to prevent extrusion and maintain seal integrity.

- If your primary focus is dynamic wear on a soft shaft: The enhanced lubricity from graphite minimizes friction and prevents galling, extending the life of both the seal and the shaft.

- If your primary focus is high-speed or heat-generating applications: The carbon filler's ability to improve thermal conductivity is critical for dissipating frictional heat and preventing premature failure.

Ultimately, carbon and graphite-filled PTFE is an engineered solution that transforms a good material into a great one for challenging industrial tasks.

Summary Table:

| Property | Benefit |

|---|---|

| Enhanced Strength | Resists deformation and cold creep under heavy loads. |

| Improved Wear Resistance | Carbon provides durability; graphite acts as a solid lubricant. |

| Better Heat Dissipation | Carbon improves thermal conductivity for high-speed applications. |

| Self-Lubricating | Low friction reduces wear on components and soft metal shafts. |

Need a high-performance sealing or bearing solution?

Carbon and graphite-filled PTFE from KINTEK solves the core weaknesses of standard PTFE, providing the durability and lubricity required for demanding applications in the semiconductor, medical, laboratory, and industrial sectors.

We specialize in the precision manufacturing and custom fabrication of PTFE components—from prototypes to high-volume orders—ensuring your application performs reliably under stress.

Contact KINTEK today to discuss your specific requirements and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Three Neck Flasks for Advanced Chemical Applications

People Also Ask

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers