In extreme environments, Teflon (PTFE) bearings are specified for applications involving exceptionally high and low temperatures, aggressive chemical exposure, and high-load or high-speed conditions. Their unique molecular structure allows them to function reliably where traditional metal or lubricated bearings would quickly fail, making them critical components in aerospace, chemical processing, and heavy machinery.

The core reason Teflon bearings excel in harsh conditions is their combination of three key properties: an extremely wide operating temperature range, near-universal chemical inertness, and a naturally low coefficient of friction that eliminates the need for external lubrication.

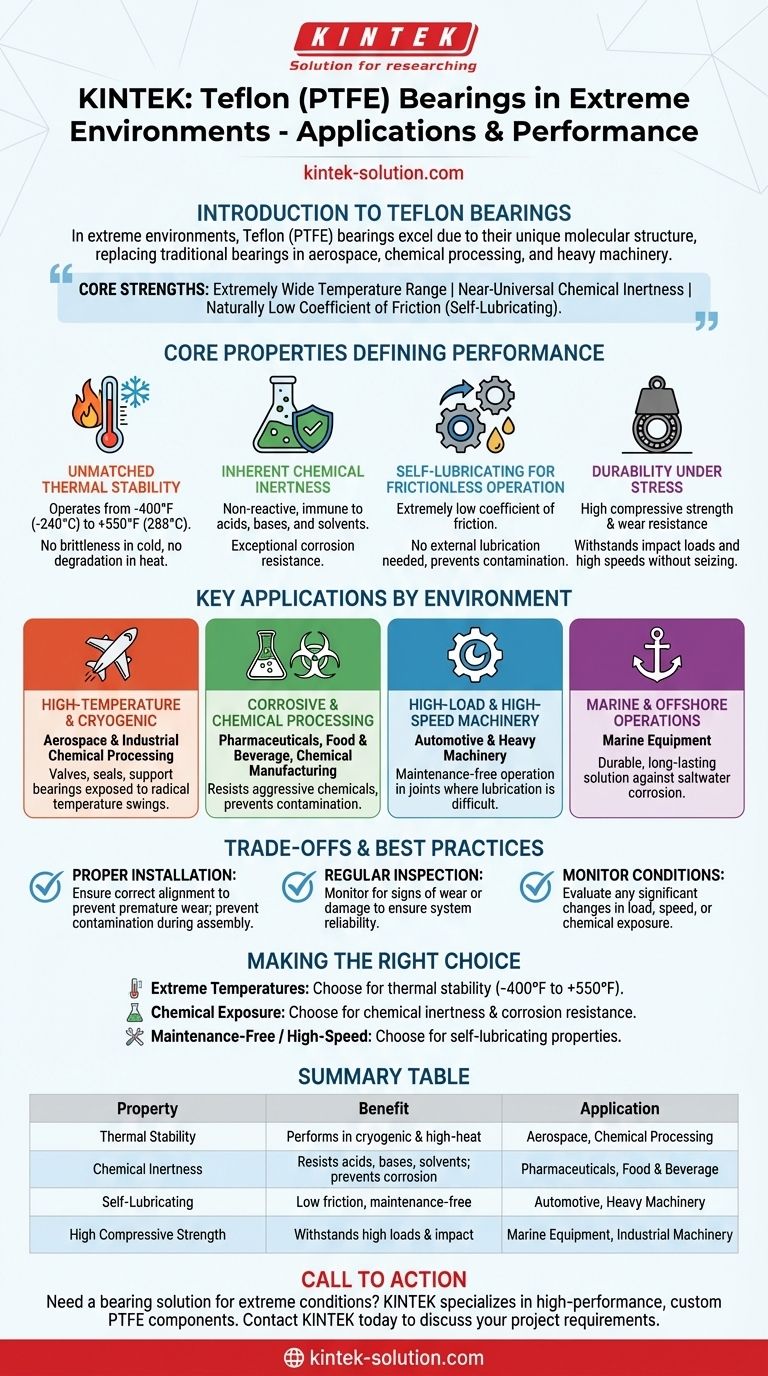

The Core Properties Defining Teflon's Performance

To understand Teflon's applications, we must first understand the material science that makes it so resilient. Its performance is not based on a single attribute but on the synergy of several inherent characteristics.

Unmatched Thermal Stability

Teflon bearings operate effectively across a vast temperature spectrum, from cryogenic lows of -400°F (-240°C) to high-heat environments of +550°F (288°C). This stability ensures that the material does not become brittle in the cold or degrade in the heat, maintaining its structural integrity and performance.

Inherent Chemical Inertness

PTFE is one of the most non-reactive substances known. This chemical inertness makes it almost completely immune to degradation from acids, bases, and aggressive solvents. As a result, it provides exceptional corrosion resistance.

Self-Lubricating for Frictionless Operation

Teflon possesses an extremely low coefficient of friction, one of the lowest of any solid material. This allows it to function as a self-lubricating surface, which is critical in environments where liquid lubricants would contaminate the process, freeze, or burn off.

Durability Under Stress

Despite its smooth surface, Teflon offers high compressive strength and wear resistance. It can withstand significant impact loads and high speeds without galling or seizing, ensuring smooth and quiet operation over a long lifespan.

Key Applications by Environment

These fundamental properties translate directly into reliable performance across a range of demanding industries. Each environment leverages a specific combination of Teflon's strengths.

High-Temperature and Cryogenic Systems

In industries like aerospace and industrial chemical processing, components are exposed to radical temperature swings. Teflon's ability to perform reliably from -400°F to +550°F makes it an ideal choice for valves, seals, and support bearings in these applications.

Corrosive and Chemical Processing

For pharmaceuticals, food and beverage, and chemical manufacturing, preventing contamination and resisting corrosive agents is paramount. Teflon's chemical inertness ensures that the bearing will not react with the processed materials or degrade from exposure to harsh cleaning agents.

High-Load and High-Speed Machinery

In automotive and heavy machinery applications, the self-lubricating nature of Teflon is a major advantage. It allows for maintenance-free operation in high-speed and high-load joints where consistent lubrication is difficult to achieve.

Marine and Offshore Operations

The marine environment is a constant battle against saltwater corrosion. Teflon's resistance to corrosion and chemicals makes it a durable, long-lasting solution for bearings in marine equipment, where maintenance can be difficult and costly.

Understanding the Trade-offs and Best Practices

While highly capable, the successful implementation of Teflon bearings depends on acknowledging their operational requirements. Proper handling and monitoring are essential to achieving their maximum performance and lifespan.

Proper Installation is Non-Negotiable

The effectiveness of any bearing is compromised by poor installation. Ensuring proper alignment is critical, as misalignment can concentrate stress and lead to premature wear. Likewise, preventing contamination during assembly is key to a smooth, low-friction interface.

The Importance of Regular Inspection

In extreme applications, regular visual inspection for signs of wear or damage is a vital best practice. While Teflon is maintenance-free from a lubrication standpoint, monitoring its physical condition ensures system reliability.

Monitoring Operating Conditions

Even Teflon has its limits. Any significant, unplanned changes in load, speed, or chemical exposure should be evaluated. Consistently monitoring the operating conditions is the best way to troubleshoot issues and prevent unexpected failure.

Making the Right Choice for Your Environment

To select the correct bearing, match the primary challenge of your operating environment to Teflon's core strengths.

- If your primary focus is extreme temperatures: Teflon's thermal stability from -400°F to +550°F provides a reliable solution where other materials would fail.

- If your primary focus is chemical exposure: Its chemical inertness and corrosion resistance make it the default choice for chemically aggressive or sterile environments.

- If your primary focus is maintenance-free or high-speed operation: Teflon's self-lubricating properties reduce system complexity and ensure smooth performance under high loads.

Ultimately, choosing Teflon is a decision to prioritize reliability and longevity in conditions that push materials to their absolute limits.

Summary Table:

| Property | Benefit | Application |

|---|---|---|

| Thermal Stability (-400°F to +550°F) | Performs in cryogenic & high-heat environments | Aerospace, Chemical Processing |

| Chemical Inertness | Resists acids, bases, solvents; prevents corrosion | Pharmaceuticals, Food & Beverage |

| Self-Lubricating | Low friction, maintenance-free operation | Automotive, Heavy Machinery |

| High Compressive Strength | Withstands high loads and impact | Marine Equipment, Industrial Machinery |

Need a bearing solution for extreme conditions?

KINTEK specializes in manufacturing high-performance, custom PTFE components, including seals, liners, and labware, for the semiconductor, medical, laboratory, and industrial sectors. Our precision production ensures your components withstand the harshest environments, from cryogenic temperatures to aggressive chemical exposure.

Let us provide a reliable, long-lasting solution tailored to your specific needs, from prototype to high-volume production.

Contact KINTEK today to discuss your project requirements.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications