At their core, PTFE-lined bottle caps are the definitive solution for applications where product purity and chemical inertness are non-negotiable. They are mission-critical for storing aggressive laboratory chemicals, high-purity pharmaceutical reagents, sensitive environmental samples, and other materials that cannot risk contamination or reaction with their container.

The defining feature of a PTFE-lined cap is the liner's near-total chemical inertness. This makes it the default choice for containing substances that would otherwise degrade, contaminate, or be contaminated by a standard cap material.

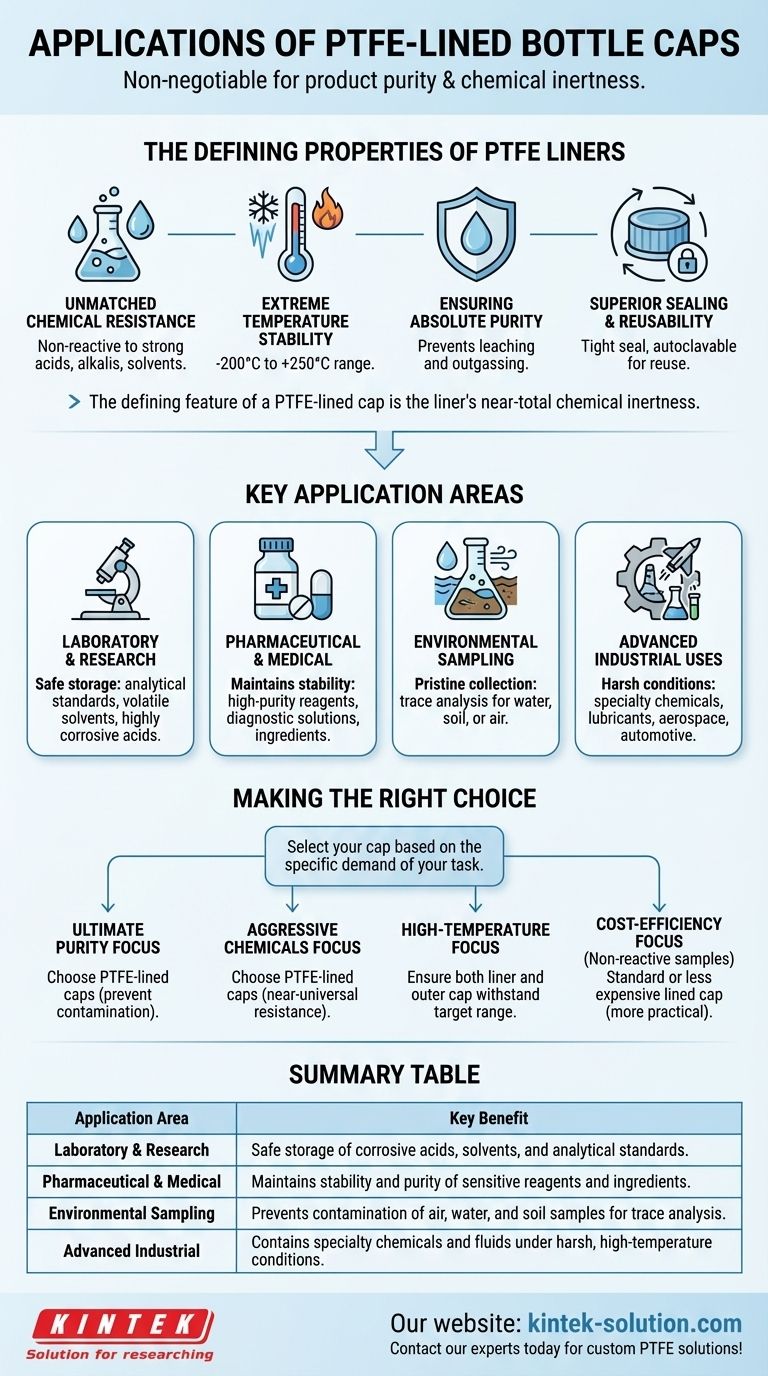

The Defining Properties of PTFE Liners

To understand the applications, you must first understand the unique characteristics of Polytetrafluoroethylene (PTFE). The value is not in the cap itself, but in the thin, powerful barrier it holds.

Unmatched Chemical Resistance

PTFE is renowned for its exceptional non-reactivity. It provides a reliable barrier against a vast range of aggressive substances, including strong acids, alkalis, organic solvents, and corrosive chemicals.

This inertness ensures the contents of the container remain pure and the cap liner itself does not degrade over time, preventing leaks and failures.

Extreme Temperature Stability

The material maintains its integrity across a remarkably wide thermal range, typically from -200°C to +250°C (-328°F to +482°F).

This makes PTFE-lined caps suitable for applications involving cryo-storage, autoclaving, or processes with significant temperature fluctuations.

Ensuring Absolute Purity

Because PTFE is chemically inert, it prevents leaching or outgassing of chemicals from the liner into the sample.

This property is critical in pharmaceutical and diagnostic applications where even trace levels of contamination can invalidate results or compromise product safety.

Superior Sealing and Reusability

PTFE liners create a tight, secure seal, and their low-friction, non-stick surface allows for easy and consistent cap removal without binding.

Furthermore, these liners are often autoclavable, allowing for sterilization and reuse in laboratory or medical environments, which can be a cost-effective advantage.

Key Application Areas in Detail

The properties of PTFE directly translate into its use across several demanding industries where performance and reliability are paramount.

Laboratory and Research

In a lab setting, these caps are essential for the safe, long-term storage of analytical standards, volatile solvents, and highly corrosive acids. They guarantee that the chemical composition of the stored substance remains unchanged.

Pharmaceutical and Medical

PTFE liners are used to seal vials containing high-purity chemical reagents, diagnostic solutions, and pharmaceutical ingredients. The non-reactive surface is critical for maintaining the stability and efficacy of these sensitive products.

Environmental Sampling

When collecting water, soil, or air samples for trace analysis, it is vital to prevent contamination. PTFE-lined caps ensure that the collected sample remains pristine and that no external compounds are introduced from the container seal.

Advanced Industrial Uses

Industries such as aerospace, chemical processing, and automotive use PTFE-lined caps for containing specialty chemicals, lubricants, and fluids under harsh conditions, relying on their robust chemical and thermal resistance.

Understanding the Trade-offs

While highly effective, PTFE-lined caps are a specialized tool. Understanding their limitations is key to using them appropriately.

Cost Consideration

PTFE is a high-performance polymer, and its cost reflects that. For storing benign substances like water or simple buffers, a PTFE-lined cap is often unnecessary and not cost-effective.

The Cap Body Still Matters

The liner provides the chemical barrier, but the outer cap provides the structural integrity. The cap's material (e.g., polypropylene, phenolic) dictates the overall mechanical strength and temperature tolerance. You must ensure both the liner and the cap body are compatible with your application.

Making the Right Choice for Your Goal

Select your cap based on the specific demand of your task.

- If your primary focus is ultimate purity: Choose PTFE-lined caps to prevent any possibility of leaching or sample contamination.

- If your primary focus is storing aggressive chemicals: The near-universal chemical resistance of PTFE makes it the safest and most reliable choice.

- If your primary focus is high-temperature applications: Ensure both the PTFE liner and the outer cap material can withstand your target temperature range.

- If your primary focus is cost-efficiency for non-reactive samples: A standard, unlined cap or one with a less expensive liner is a more practical option.

By understanding its core properties, you can deploy a PTFE-lined cap as a precise solution for your most demanding containment challenges.

Summary Table:

| Application Area | Key Benefit |

|---|---|

| Laboratory & Research | Safe storage of corrosive acids, solvents, and analytical standards. |

| Pharmaceutical & Medical | Maintains stability and purity of sensitive reagents and ingredients. |

| Environmental Sampling | Prevents contamination of air, water, and soil samples for trace analysis. |

| Advanced Industrial | Contains specialty chemicals and fluids under harsh, high-temperature conditions. |

Need a reliable sealing solution for aggressive chemicals or high-purity applications?

KINTEK specializes in manufacturing high-precision PTFE components, including custom PTFE-lined caps, seals, and labware. We serve demanding industries like semiconductor, medical, and laboratory, where contamination is not an option.

Our expertise ensures your components offer:

- Guaranteed Chemical Inertness: For use with strong acids, alkalis, and solvents.

- Superior Sealing & Reusability: Autoclavable and reliable for repeated use.

- Custom Fabrication: From prototype development to high-volume production runs.

Let us help you protect your most critical samples and reagents. Contact our experts today to discuss your specific requirements!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Bottles for Diverse Industrial Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What are the primary applications of PTFE fasteners and custom parts? Critical Solutions for Extreme Environments

- Why is PTFE suitable for cryogenic or high-temperature applications? Unmatched Thermal Stability from -450°F to 500°F