To be precise, PTFE laminated fabric is a critical material for special apparel where protection and comfort must coexist. Its primary applications include high-performance medical gowns for pathogen resistance, specialized gear for first responders when bonded with flame-retardant layers, and advanced waterproof, breathable footwear for both professional and recreational use.

The core value of PTFE laminated fabric lies in its unique microporous structure. This structure acts as a selective barrier—it is impenetrable to liquids like water and blood, yet permeable to water vapor, allowing sweat to escape and ensuring wearer comfort in demanding environments.

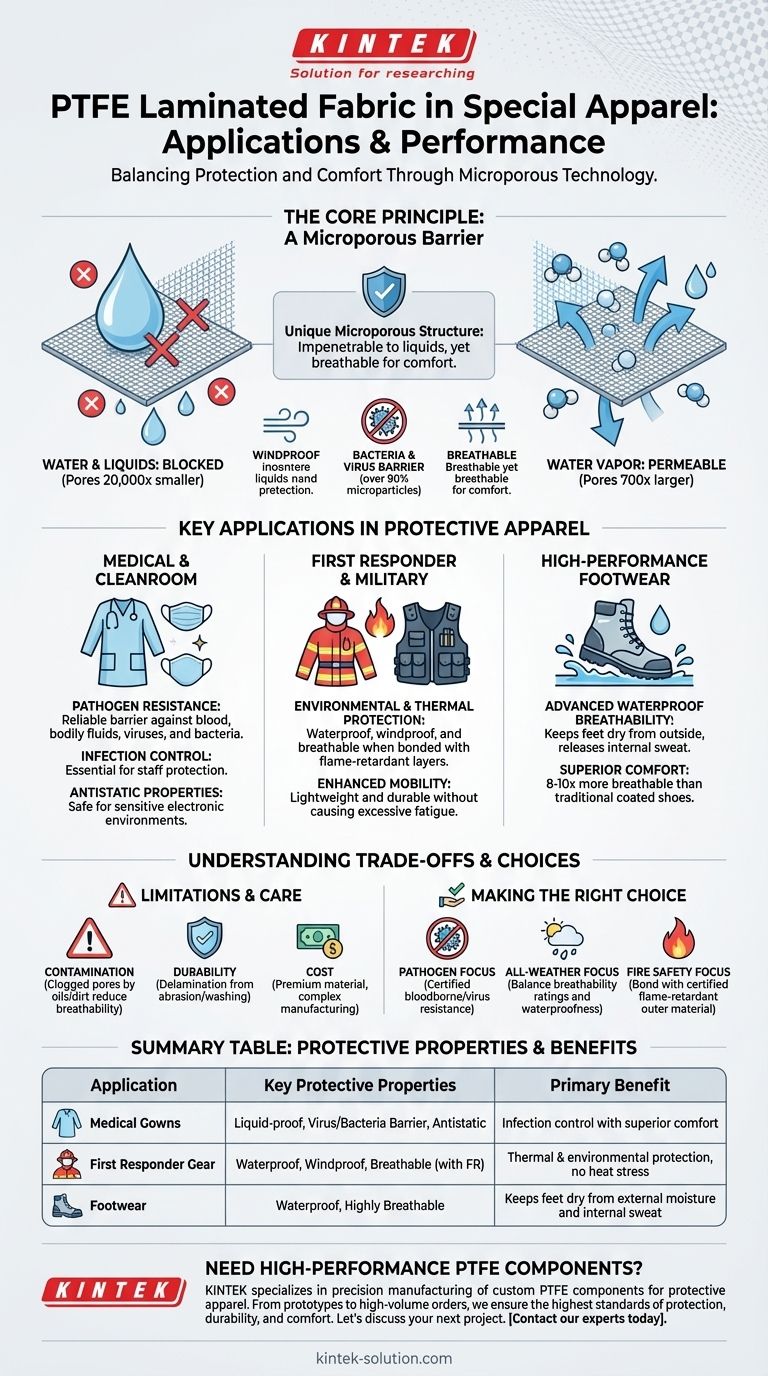

The Core Principle: A Microporous Barrier

The technology behind PTFE laminated fabric is elegantly simple yet highly effective. It revolves around a thin membrane of expanded Polytetrafluoroethylene (ePTFE) that is bonded to a base fabric.

The "Smart Screen Door" Effect

Think of the PTFE membrane as a microscopic screen door. Its pores are approximately 20,000 times smaller than a water droplet, making it impossible for rain, bodily fluids, or other liquid contaminants to pass through. This ensures complete waterproofness.

At the same time, these pores are about 700 times larger than a water vapor molecule. This allows perspiration vapor from the body to escape easily, a property known as breathability. This dual function prevents the wearer from getting wet from the outside while also preventing overheating and moisture buildup on the inside.

More Than Just Waterproofing

Beyond its famous waterproof and breathable properties, the tightly woven structure of the PTFE membrane provides additional protective benefits. It is an excellent windproof barrier and can block over 90% of microparticles, making it effective against fine dust, bacteria, and viruses.

Key Applications in Protective Apparel

The unique combination of protection and comfort makes PTFE laminated fabrics indispensable in several specialized fields.

Medical and Cleanroom Environments

In medical settings, protecting staff from pathogens is paramount. PTFE laminated fabrics are used in surgical gowns and uniforms to provide a reliable barrier against blood penetration and other bodily fluids.

Its microporous structure is fine enough to act as a virus and bacteria barrier, a critical feature for infection control. Furthermore, these fabrics can be engineered to have antistatic properties, which is vital when working around sensitive electronic medical equipment.

First Responder and Military Gear

When laminated to a flame-retardant outer fabric, this composite material is used to create protective gear for firefighters and other first responders. It provides thermal protection from the outer layer while the PTFE membrane offers a waterproof barrier and allows metabolic heat to escape.

For military and tactical applications, its lightweight, windproof, and durable nature provides environmental protection without hindering mobility or causing excessive fatigue.

High-Performance Footwear

PTFE membrane linings are frequently bonded to leather or textile uppers to create waterproof boots and shoes. This application offers a significant advantage over traditional coated waterproof shoes, which often lack breathability.

The result is footwear that keeps feet dry from external moisture while being eight to ten times more breathable, drastically improving comfort during strenuous activity.

Understanding the Practical Trade-offs

While highly effective, PTFE laminated fabrics are not without their limitations. Acknowledging these trade-offs is crucial for proper material selection and care.

Contamination and Reduced Breathability

The microscopic pores that allow for breathability can become clogged by oils, sweat residue, dirt, and detergent particles. Over time, this contamination can significantly reduce the fabric's ability to transmit water vapor, making it feel less breathable.

Durability of the Lamination

The performance of the final garment depends on the integrity of the bond between the PTFE membrane and the outer fabric. Physical abrasion, improper washing, or age can cause delamination, which compromises the waterproof and windproof capabilities of the apparel.

Cost and Specialization

PTFE laminated fabric is a premium, high-performance material. Its complex manufacturing process and superior properties mean it is significantly more expensive than standard waterproof coatings or less advanced fabrics.

Making the Right Choice for Your Goal

Selecting the correct composite fabric construction is critical and depends entirely on the primary hazard you need to mitigate.

- If your primary focus is pathogen protection: Seek a laminate certified for resistance to bloodborne pathogens and viruses, ensuring the pore structure and fabric integrity meet medical standards.

- If your primary focus is all-weather performance: Prioritize a balance between high breathability ratings (measured in g/m²/24h) and robust waterproofness (measured in mm), laminated to a durable, abrasion-resistant face fabric.

- If your primary focus is fire safety: Ensure the PTFE membrane is bonded to an outer material with the appropriate, certified flame-retardant properties for your specific application.

Ultimately, understanding the fundamental properties of the PTFE membrane allows you to specify a laminated fabric that delivers precisely the protection your application demands.

Summary Table:

| Application | Key Protective Properties | Primary Benefit |

|---|---|---|

| Medical Gowns & Cleanroom Apparel | Liquid-proof (blood, fluids), Bacteria/Virus Barrier, Antistatic | Infection control with superior wearer comfort |

| First Responder & Military Gear | Waterproof, Windproof, Breathable (when bonded to FR fabric) | Thermal and environmental protection without heat stress |

| High-Performance Footwear | Waterproof, Highly Breathable | Keeps feet dry from external moisture and internal sweat |

Need High-Performance PTFE Components for Your Protective Apparel?

KINTEK specializes in the precision manufacturing of custom PTFE components, including the advanced materials that make protective apparel possible. Whether you are developing medical gowns, firefighter gear, or specialized footwear, our expertise in PTFE fabrication—from prototypes to high-volume orders—ensures your products meet the highest standards of protection, durability, and comfort.

Let's discuss how our PTFE solutions can enhance your next project. Contact our experts today for a consultation!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application