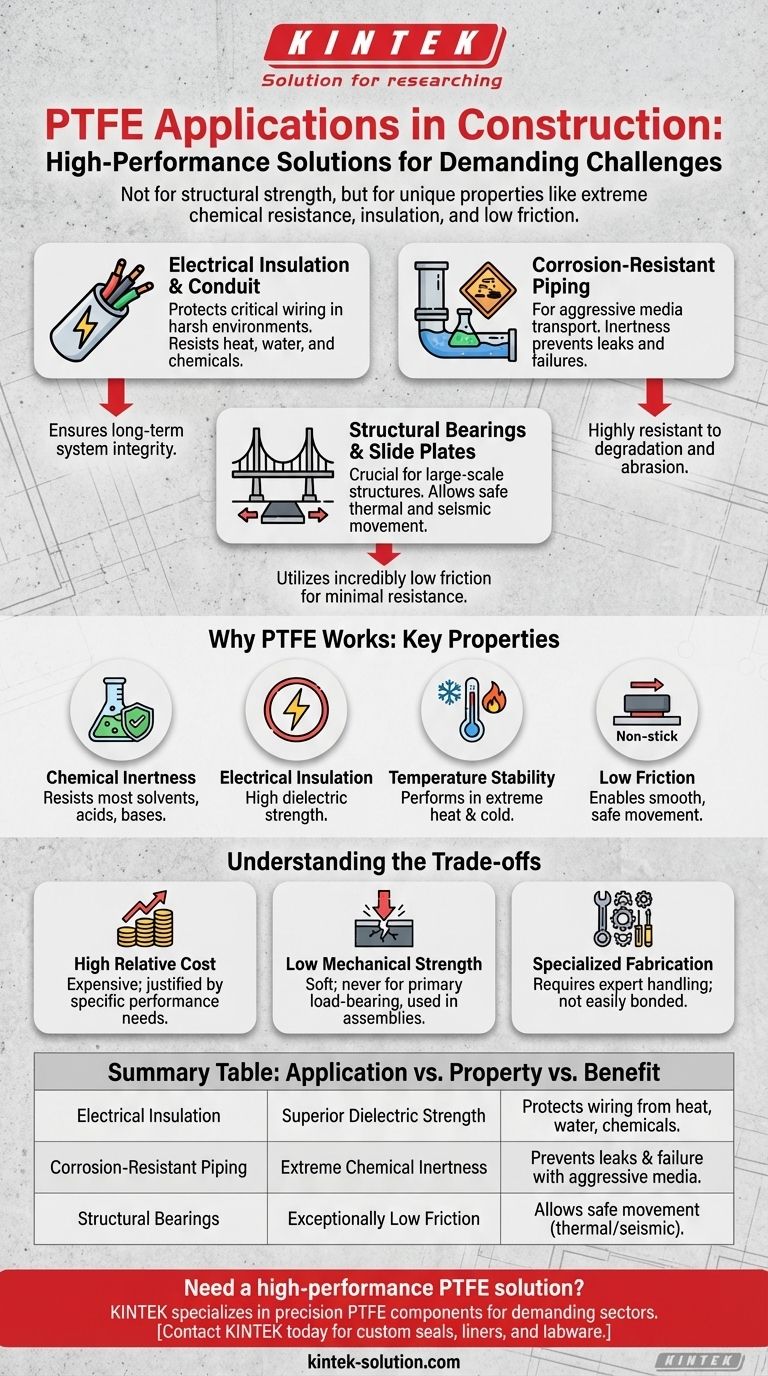

In the construction industry, PTFE (Polytetrafluoroethylene) serves as a high-performance problem-solver for specific, demanding applications. Its primary uses are in protecting electrical wiring, creating corrosion-proof pipes and hoses for aggressive media, and—most critically—in structural bearings that allow large structures like bridges to move safely.

The core reason PTFE is valued in construction is not for its structural strength, but for its unique combination of properties: extreme chemical and temperature resistance, excellent electrical insulation, and an exceptionally low coefficient of friction. It is a material chosen to solve challenges where conventional materials would fail.

Core Applications in Construction

PTFE's applications are highly specialized, focusing on protection, durability, and managing movement within a structure.

Electrical Insulation and Conduit

PTFE is an exceptional electrical insulator. It is used to encase and protect critical electrical wiring within buildings and infrastructure.

This is because it is highly resistant to heat, water, and chemical exposure, ensuring the long-term integrity and safety of electrical systems in harsh environments.

Corrosion-Resistant Piping and Liners

For projects involving the transport of corrosive chemicals or gases, PTFE is used for pipes, hoses, and liners. This is common in industrial construction or specialized facilities.

Its chemical inertness means it will not corrode or degrade when exposed to aggressive substances, preventing leaks and system failure. It is also resistant to abrasion, adding to its durability.

Structural Bearings and Slide Plates

Perhaps its most significant use in large-scale construction is in structural bearings. These are pads placed between major structural elements, such as between a bridge deck and its support piers.

PTFE's incredibly low friction allows these elements to slide past each other with minimal resistance. This movement is essential to safely accommodate thermal expansion and contraction, as well as shifts from wind or seismic activity.

The Properties Driving PTFE's Use

PTFE is not a general-purpose building material. It is selected when one of its distinct, high-performance properties is required to solve a specific engineering problem.

Unmatched Chemical Inertness

PTFE is one of the most non-reactive substances known. It can withstand exposure to a vast range of solvents, acids, and bases without corroding, making it ideal for pipes, gaskets, and tank linings in industrial settings.

Superior Electrical Insulation

The material has a very high dielectric strength, meaning it can withstand strong electric fields without breaking down. This makes it a reliable choice for insulating high-voltage or mission-critical wiring.

Extreme Temperature Stability

PTFE performs reliably across a wide temperature range. It maintains its properties in both high-heat applications and cryogenic-level cold, a versatility that few other polymers can match.

Exceptionally Low Friction

Known for its "non-stick" quality, PTFE has one of the lowest coefficients of friction of any solid material. This property is the entire basis for its use in slide bearings, enabling massive structural components to move without destructive stress.

Understanding the Trade-offs

While powerful, PTFE is not a universal solution. Its selection requires a clear understanding of its limitations.

High Relative Cost

Compared to commodity plastics like PVC or metals like steel, PTFE is significantly more expensive. Its use is only justified when its specific performance characteristics are essential for the application's safety and longevity.

Low Mechanical Strength

PTFE is a relatively soft material with low tensile strength. It is never used as a primary structural load-bearing material on its own. Instead, it is integrated into a larger assembly, such as a steel bearing plate, where its properties can be leveraged.

Specialized Fabrication

Working with PTFE often requires specialized tools and expertise. It cannot be welded or bonded with conventional adhesives, and its fabrication must account for its unique thermal expansion properties.

Making the Right Choice for Your Project

The decision to specify PTFE should be driven entirely by the unique demands of the application.

- If your primary focus is protecting electrical wiring or transporting corrosive fluids: PTFE offers unparalleled resistance to chemical, thermal, and water damage, ensuring maximum system integrity.

- If your primary focus is managing thermal expansion or seismic movement in large structures: PTFE slide bearings are the industry standard for creating a low-friction surface that allows for controlled structural movement.

- If your primary focus is general structural framing, standard plumbing, or cost-sensitive elements: Conventional materials like steel, concrete, and PVC are far more appropriate and cost-effective.

Ultimately, PTFE is a specialized tool used to engineer solutions for the most demanding environmental and mechanical challenges in modern construction.

Summary Table:

| Application | Key PTFE Property Used | Primary Benefit |

|---|---|---|

| Electrical Insulation | Superior Dielectric Strength | Protects wiring from heat, water, and chemicals |

| Corrosion-Resistant Piping | Extreme Chemical Inertness | Prevents leaks and failure with aggressive media |

| Structural Bearings | Exceptionally Low Friction | Allows safe movement from thermal expansion/seismic activity |

Need a high-performance PTFE solution for your construction project?

KINTEK specializes in manufacturing precision PTFE components—including custom seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. We combine expert fabrication with a focus on durability and chemical resistance, delivering from prototypes to high-volume orders.

Contact KINTEK today to discuss how our PTFE expertise can ensure the longevity and safety of your critical applications.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments