In the aerospace industry, PTFE chevron packing is a critical sealing component used in high-performance hydraulic systems, actuators, valves, and pumps. Its primary role is to prevent fluid leaks and maintain system pressure under the extreme operating conditions inherent to flight, from drastic temperature shifts to intense mechanical stress.

The core reason PTFE chevron packing is chosen for aerospace is its unique combination of material and design. PTFE provides unmatched thermal stability and chemical inertness, while the V-shaped "chevron" design creates a highly reliable, self-adjusting seal that performs exceptionally well under high pressure.

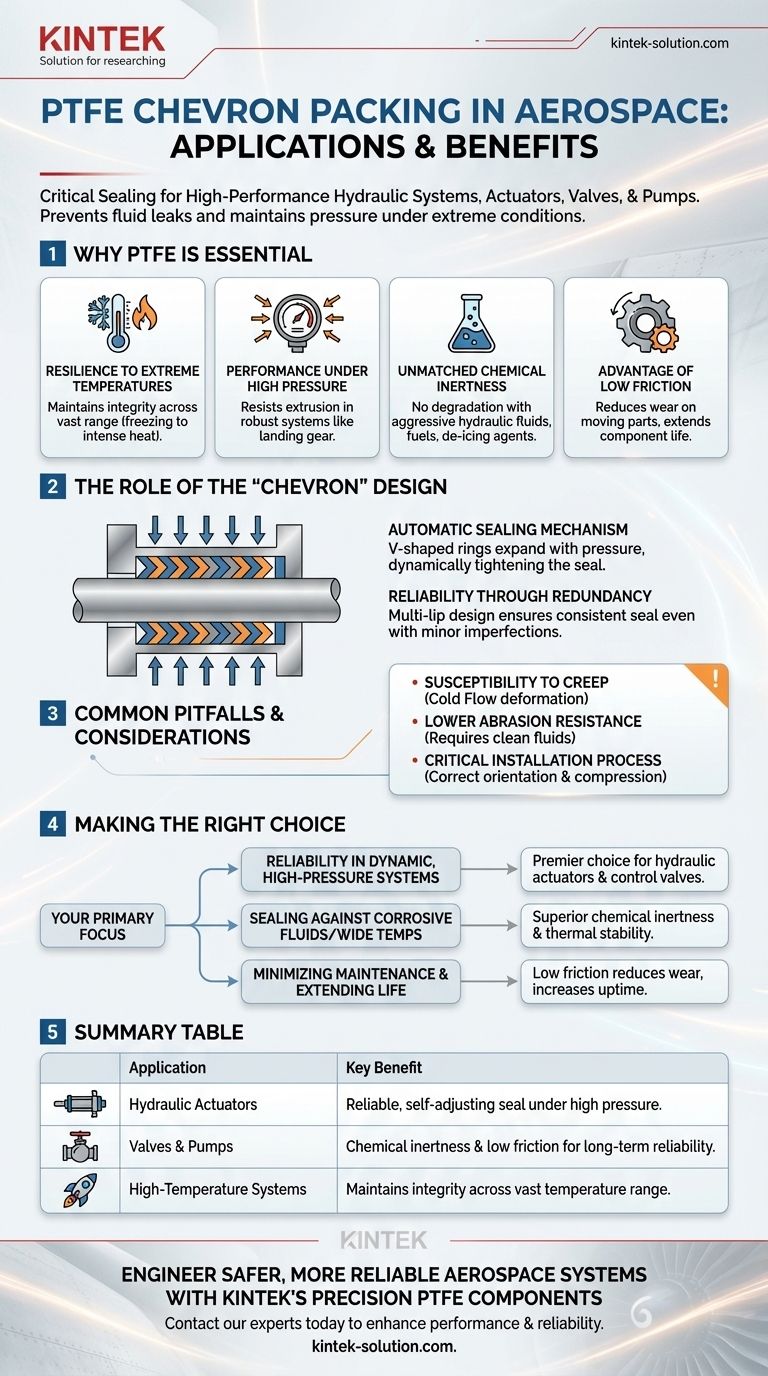

Why PTFE is Essential for Aerospace Sealing

The selection of any material for aerospace applications is a matter of extreme scrutiny. PTFE (Polytetrafluoroethylene) possesses a set of fundamental properties that make it uniquely suited for the demanding sealing challenges in this industry.

Resilience Under Extreme Temperatures

Aerospace components must function flawlessly from the freezing temperatures of high altitude to the intense heat generated by engines and hydraulic systems. PTFE maintains its integrity and performance characteristics across a vast temperature range, unlike many elastomers that can become brittle or degrade.

Performance Under High Pressure

Hydraulic systems in aircraft, such as those for landing gear and flight control surfaces, operate under immense pressure. PTFE is a robust material that resists extrusion, ensuring the seal does not fail when subjected to these forces.

Unmatched Chemical Inertness

Aircraft systems use a variety of aggressive fluids, including hydraulic oils, fuels, and de-icing agents. PTFE is virtually inert and does not react with or degrade when exposed to these corrosive chemicals, ensuring long-term reliability.

The Advantage of Low Friction

A key characteristic of PTFE is its extremely low coefficient of friction. In dynamic applications like actuators and valve stems, this property is critical for reducing wear and tear on moving parts, which minimizes maintenance and extends the operational life of the entire component.

The Role of the "Chevron" Design

The effectiveness of the seal comes not just from the PTFE material, but also from the specific engineering of the chevron packing stack.

An Automatic Sealing Mechanism

Chevron packing consists of a stack of V-shaped rings. This design is not a simple compression seal; it is an automatic seal. As system pressure increases, it acts on the "V" shape, forcing the rings outwards against the shaft and housing, thereby tightening the seal dynamically.

Reliability Through Redundancy

Using multiple rings in a stack creates redundancy. This multi-lip design ensures a consistent and reliable seal even with minor imperfections or wear, a critical safety feature for aerospace equipment. This design significantly enhances the safety and reliability of pumps, valves, and other mechanical equipment.

Common Pitfalls and Considerations

While highly effective, specifying and using PTFE chevron packing requires an understanding of its limitations to ensure optimal performance.

Susceptibility to Creep

PTFE can be subject to "cold flow" or creep, which is a slow deformation under sustained pressure. This must be accounted for during the design of the gland and the selection of the specific PTFE compound, as filled grades can mitigate this effect.

Lower Abrasion Resistance

Compared to harder materials, pure PTFE can be more susceptible to wear from abrasive contaminants in a system. Proper fluid filtration and system cleanliness are therefore crucial for maximizing the life of the seals.

Critical Installation Process

The performance of chevron packing is highly dependent on proper installation. Unlike simple O-rings, the packing stack must be installed with the correct orientation and compressed appropriately. Over-tightening can crush the rings and prevent the automatic sealing function from working correctly.

Making the Right Choice for Your System

Selecting the correct sealing solution is a critical design decision that directly impacts safety and reliability. Your choice should be guided by the primary demands of the application.

- If your primary focus is reliability in dynamic, high-pressure systems: PTFE chevron packing is a premier choice for components like hydraulic actuators and control valves where failure is not an option.

- If your primary focus is sealing against corrosive fluids or across wide temperatures: The inherent chemical inertness and thermal stability of PTFE make it far superior to most rubber-based seals in these environments.

- If your primary focus is minimizing maintenance and extending component life: The low-friction nature of PTFE directly reduces wear on expensive moving parts, leading to longer service intervals and greater system uptime.

Ultimately, understanding the interplay between material science and mechanical design is key to engineering safe and reliable aerospace systems.

Summary Table:

| Application | Key Benefit of PTFE Chevron Packing |

|---|---|

| Hydraulic Actuators | Reliable, self-adjusting seal under high pressure for flight controls and landing gear. |

| Valves & Pumps | Chemical inertness and low friction for long-term reliability with aggressive fluids. |

| High-Temperature Systems | Maintains integrity across a vast temperature range, from freezing altitudes to engine heat. |

Engineer safer, more reliable aerospace systems with KINTEK's precision PTFE components.

For demanding applications in the semiconductor, medical, laboratory, and industrial sectors, KINTEK manufactures high-performance PTFE seals, liners, and labware. We prioritize precision production and offer custom fabrication from prototypes to high-volume orders to meet your exact specifications.

Contact our experts today to discuss how our PTFE solutions can enhance your product's performance and reliability.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What are the base characteristics of PTFE? Unlocking Extreme Performance in Friction, Temperature, and Chemical Resistance

- Why is PTFE suitable for cryogenic or high-temperature applications? Unmatched Thermal Stability from -450°F to 500°F

- What are the primary applications of PTFE fasteners and custom parts? Critical Solutions for Extreme Environments

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications