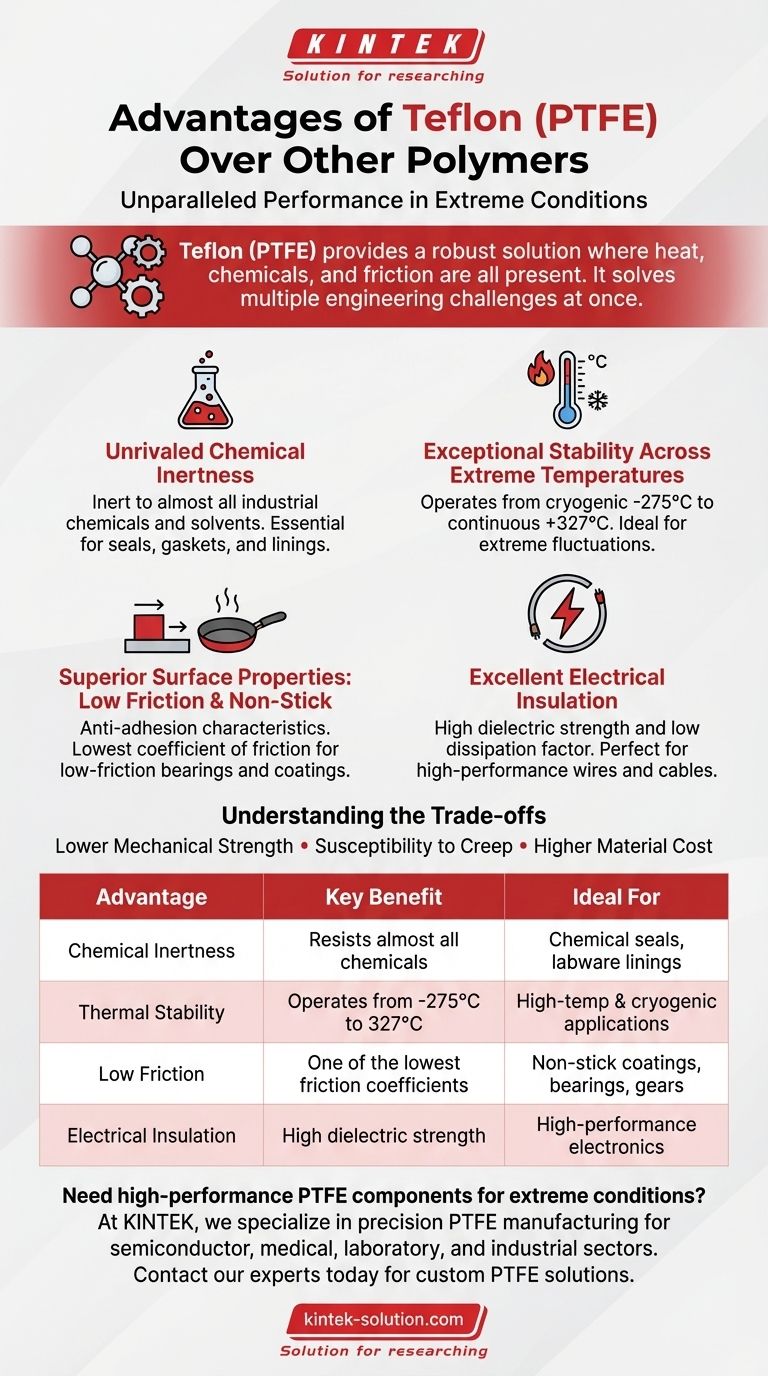

The primary advantage of Teflon over other polymers is its unparalleled performance in extreme conditions, specifically its unique combination of near-total chemical inertness, a very wide operational temperature range, and one of the lowest coefficients of friction of any solid material. While other polymers may excel in one area, such as strength, Teflon (PTFE) provides a robust solution where heat, chemicals, and friction are all present.

The core reason to choose Teflon is not for a single attribute, but for its remarkable ability to solve multiple engineering challenges at once. It maintains its integrity in environments where heat, aggressive chemicals, and the need for a non-stick, low-friction surface would cause nearly any other polymer to fail.

Why Teflon Excels in Demanding Environments

Teflon, the brand name for Polytetrafluoroethylene (PTFE), is a fluoropolymer. Its unique properties stem from the extremely strong carbon-fluorine bonds that make up its molecular structure. This chemical foundation gives it a set of advantages that are difficult to match.

Unrivaled Chemical Inertness

The most notable property of Teflon is its resistance to chemical attack. It is inert to almost all industrial chemicals and solvents.

This includes various concentrations of acids, alkalis, strong oxidants, and organic solvents. This makes it an essential material for seals, gaskets, O-rings, and linings in chemical processing and laboratory equipment.

Exceptional Stability Across Extreme Temperatures

Teflon operates reliably across an exceptionally wide temperature range, a feat few other polymers can achieve.

It remains functional and stable in cryogenic conditions as low as -275°C and can withstand continuous high temperatures up to 327°C. This makes it ideal for applications involving extreme temperature fluctuations.

Superior Surface Properties: Low Friction and Non-Stick

Teflon is famous for its anti-adhesion, or non-stick, characteristics, which is why it's used in cookware.

This property is a direct result of its extremely low coefficient of friction, one of the lowest recorded for any solid material. This makes it a first-choice material for low-friction bearings, gears, and coatings where smooth movement is critical.

Excellent Electrical Insulation

Teflon is also a superior electrical insulator, possessing a high dielectric strength and low dissipation factor.

This makes it a valuable material for insulating high-performance wires and cables, especially in aerospace and computing applications where signal integrity and resistance to heat are critical.

Understanding the Trade-offs

While Teflon's advantages are significant, it is not the ideal solution for every problem. An objective assessment requires understanding its limitations.

Lower Mechanical Strength

Compared to engineering polymers like nylon or acetal, Teflon is relatively soft and has lower tensile strength and wear resistance. It is not typically chosen for high-load structural applications.

Susceptibility to Creep

Under sustained pressure, Teflon can be subject to "creep" or cold flow, meaning it can slowly deform over time. This must be accounted for in the design of seals and gaskets.

Higher Material Cost

As a high-performance specialty polymer, Teflon is generally more expensive than common plastics. Its use is justified when its unique combination of properties is a strict requirement for performance and safety.

Making the Right Choice for Your Application

Selecting Teflon is about matching its unique profile to a specific, demanding challenge.

- If your primary focus is sealing aggressive chemicals: Teflon's near-total chemical inertness makes it the safest and most reliable choice for gaskets and O-rings.

- If your primary focus is reducing friction in a high-temperature system: Teflon's combination of thermal stability and a low friction coefficient is unmatched.

- If your primary focus is high-frequency electrical insulation: Teflon's excellent dielectric properties ensure signal integrity in demanding electronic applications.

- If your primary focus is pure structural strength: You should likely consider other engineering polymers that offer better mechanical properties.

Ultimately, choosing Teflon is a decision to prioritize performance and reliability in environments where other materials would simply fail.

Summary Table:

| Advantage | Key Benefit | Ideal For |

|---|---|---|

| Chemical Inertness | Resists almost all industrial chemicals and solvents. | Chemical seals, gaskets, labware linings. |

| Thermal Stability | Operates from -275°C to 327°C. | High-temperature systems, cryogenic applications. |

| Low Friction | One of the lowest coefficients of friction. | Non-stick coatings, low-friction bearings, gears. |

| Electrical Insulation | High dielectric strength and low dissipation factor. | High-performance wires, cables, and electronics. |

Need a high-performance PTFE component that can withstand extreme conditions?

At KINTEK, we specialize in manufacturing precision PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors. We provide custom fabrication from prototypes to high-volume orders, ensuring your components deliver the unparalleled chemical resistance, thermal stability, and low friction that Teflon is known for.

Contact our experts today to discuss how our PTFE solutions can solve your most demanding engineering challenges.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What are the base characteristics of PTFE? Unlocking Extreme Performance in Friction, Temperature, and Chemical Resistance

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- What are the key benefits of PTFE in custom fabrication? Unlock Performance in Extreme Conditions