In demanding filtration applications, Teflon (PTFE) membranes provide a level of performance that few other materials can match. Their primary advantages are superior chemical resistance and high thermal stability, which allow them to effectively filter aggressive substances and operate in extreme temperature conditions where other membrane types would degrade.

The core advantage of a Teflon membrane is its ability to ensure sample purity and integrity under the most extreme chemical and thermal conditions. It is the material of choice when the process involves harsh solvents, strong acids, or high temperatures that would compromise lesser materials.

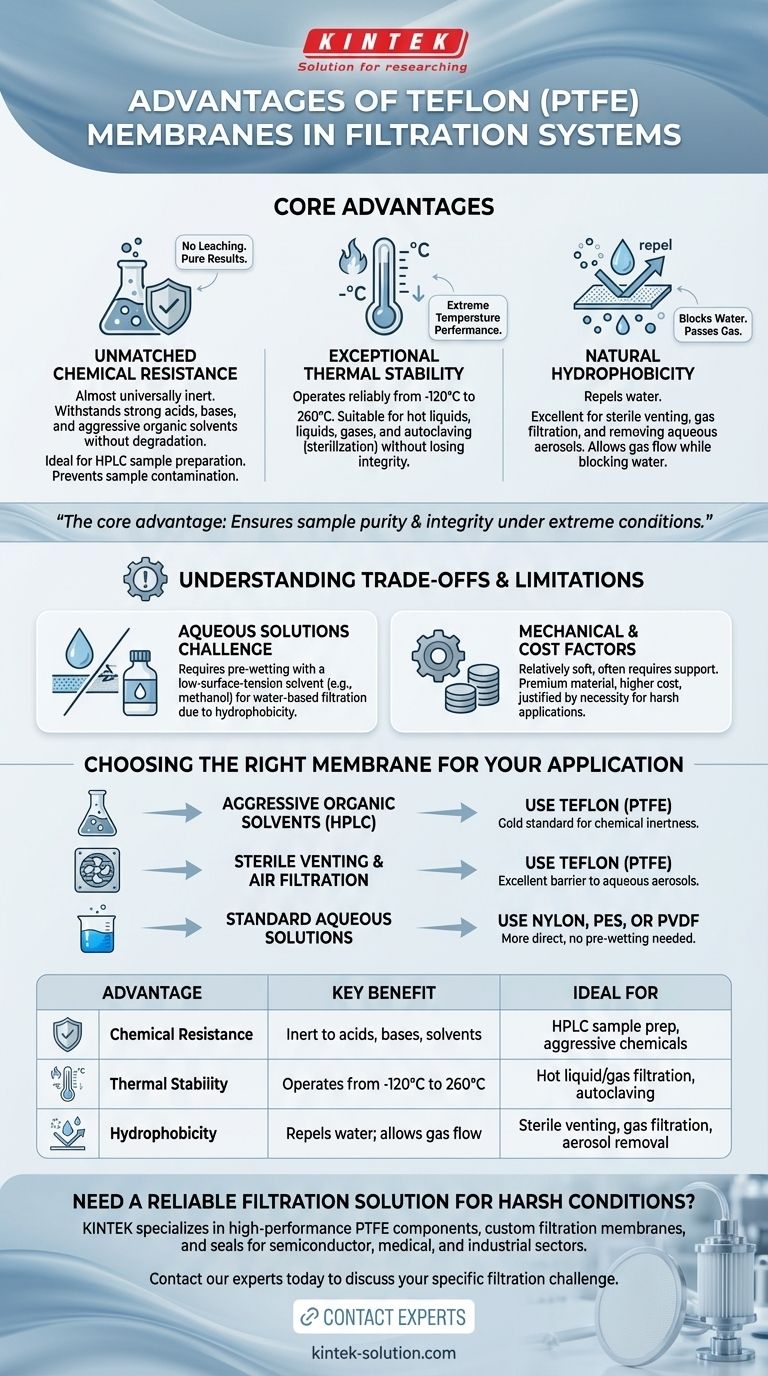

The Core Strengths of Teflon Membranes

Teflon, or Polytetrafluoroethylene (PTFE), possesses a unique combination of properties that make it an exceptional material for specialized filtration tasks, particularly in laboratory and industrial settings.

Unmatched Chemical Resistance

Teflon is renowned for being almost universally chemically inert. It can withstand exposure to a vast range of aggressive substances without degrading, swelling, or leaching contaminants into the filtrate.

This makes it the ideal choice for filtering strong acids, bases, and aggressive organic solvents that are common in applications like HPLC sample preparation. This inertness guarantees that the membrane itself does not become a source of sample contamination.

Exceptional Thermal Stability

These membranes can operate reliably across a very wide temperature range, often from -120°C to 260°C.

This stability allows for the filtration of hot liquids or gases and ensures the membrane can withstand sterilization processes like autoclaving without losing its structural integrity or filtration efficiency.

Natural Hydrophobicity

Teflon is naturally hydrophobic, meaning it repels water. While this is a disadvantage for filtering water-based liquids without pre-treatment, it is a significant advantage in other areas.

This property makes Teflon membranes excellent for sterile venting, filtering gases, or removing aqueous aerosols from a gas stream. Air and other gases pass through easily, while water droplets are effectively blocked.

Understanding the Trade-offs and Limitations

No material is perfect for every application. To make an informed decision, it's critical to understand the operational limitations of Teflon membranes.

The Challenge of Aqueous Solutions

Because Teflon is hydrophobic, pure water or aqueous solutions will not readily pass through the membrane. The high surface tension of water prevents it from wetting the pores.

To filter aqueous solutions, the membrane must first be pre-wetted with a low-surface-tension solvent like methanol or isopropanol. This adds an extra, and sometimes undesirable, step to the filtration workflow.

Mechanical Properties

While chemically robust, Teflon is a relatively soft material. In many filter formats, such as syringe filters or filter discs, the Teflon membrane requires a physical support structure (often polypropylene) to provide the necessary mechanical strength.

Cost Considerations

Teflon is a premium performance material, and its cost generally reflects that. Compared to more common membrane materials like nylon or mixed cellulose ester (MCE), Teflon filters are typically more expensive. Their use is justified by necessity, not cost-effectiveness for general-purpose filtration.

Choosing the Right Membrane for Your Application

Selecting the correct membrane material is a critical decision that directly impacts the success of your filtration process. The choice should always be driven by the specific chemical and physical demands of your sample.

- If your primary focus is filtering aggressive organic solvents (like in HPLC): Teflon is the gold standard due to its unmatched chemical inertness, ensuring no contaminants leach from the filter itself.

- If your primary focus is sterile venting or air filtration: Teflon's natural hydrophobicity makes it an excellent barrier against aqueous aerosols while allowing gas to pass freely and maintain sterility.

- If your primary focus is filtering standard aqueous solutions: A hydrophilic material like Nylon, PES, or PVDF is a more direct and cost-effective choice, as it does not require a pre-wetting step.

Ultimately, choosing a Teflon membrane is a decision to prioritize chemical and thermal resilience above all else.

Summary Table:

| Advantage | Key Benefit | Ideal For |

|---|---|---|

| Chemical Resistance | Inert to strong acids, bases, and solvents | HPLC sample prep, aggressive chemicals |

| Thermal Stability | Operates from -120°C to 260°C | Hot liquid/gas filtration, autoclaving |

| Hydrophobicity | Repels water; allows gas flow | Sterile venting, gas filtration, aerosol removal |

Need a reliable filtration solution for harsh conditions?

KINTEK specializes in manufacturing high-performance PTFE components, including custom filtration membranes, seals, and labware. We understand the critical need for purity and integrity when handling aggressive solvents, strong acids, or high-temperature processes in the semiconductor, medical, laboratory, and industrial sectors.

Our precision production and custom fabrication services—from prototypes to high-volume orders—ensure you get a component that meets your exact specifications. Let us help you protect your process and your product.

Contact our experts today to discuss your specific filtration challenge.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support