At its core, Teflon's primary advantages are its unmatched non-stick surface, extremely low friction, and exceptional resistance to both heat and chemicals. This unique combination of properties makes it a highly versatile and reliable material for challenging applications, from industrial manufacturing and aerospace to medical devices and everyday cookware.

Teflon's true value isn't just one single attribute, but its rare ability to solve multiple problems at once. It provides extreme inertness—thermally, chemically, and electrically—while also delivering one of the slickest surfaces known to science.

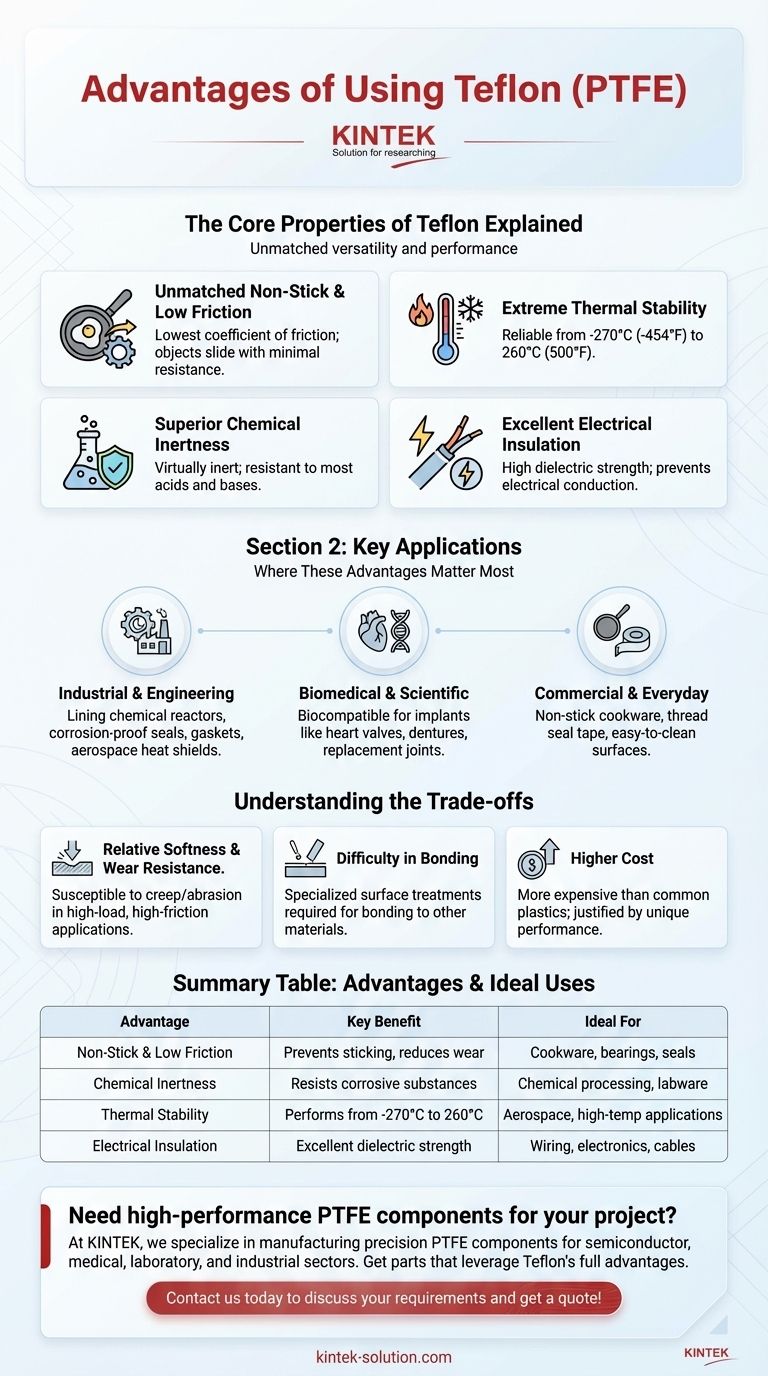

The Core Properties of Teflon Explained

To understand why Teflon (PTFE) is so widely used, we must look at each of its key characteristics and the problems they solve.

Unmatched Non-Stick and Low-Friction Surface

Teflon is renowned for having one of the lowest coefficients of friction of any solid material. This means other substances do not stick to it, and objects slide across its surface with minimal resistance.

This property is critical for applications ranging from non-stick coatings on pans to self-lubricating bearings in machinery.

Extreme Thermal Stability

This material performs reliably across an incredibly wide temperature range. It can withstand continuous service temperatures up to 260°C (500°F) and can even handle intermittent peaks near 327°C (620°F).

Simultaneously, it maintains its properties in cryogenic conditions as low as -270°C (-454°F), making it suitable for both high-heat and deep-freeze applications.

Superior Chemical Inertness

Teflon is virtually inert, meaning it does not react with the vast majority of chemicals, acids, and bases. This makes it an ideal lining for valves, pipes, and containers that handle corrosive substances.

This chemical resistance prevents contamination and ensures the long-term integrity of the equipment it protects.

Excellent Electrical Insulation

Teflon is an outstanding electrical insulator with high dielectric strength. It does not conduct electricity, making it a preferred material for insulating wires, cables, and sensitive electronic components, especially in high-frequency applications.

High Durability and Weather Resistance

Teflon is resistant to water, UV radiation, and oxidation. This allows it to endure harsh weather conditions without degrading, leading to a long service life in outdoor or exposed applications.

Its durability also means it can be cleaned and reused many times in applications like heat press sheets without losing its effectiveness.

Where These Advantages Matter Most

The combination of these properties makes Teflon indispensable across several critical industries.

In Industrial and Engineering Settings

In demanding environments, Teflon shines. It is used for lining chemical reactors, creating corrosion-proof seals and gaskets, and as a coating for parts in aerospace applications like heat shields and fuel tanks.

In Biomedical and Scientific Fields

Because it is chemically inert and biocompatible, the human body does not reject it. This allows Teflon to be used in medical implants such as artificial heart valves, dentures, and replacement joints.

In Commercial and Everyday Products

The most familiar use is in non-stick cookware, which leverages its thermal stability and non-stick surface. It is also found in thread seal tape for plumbing, which prevents leaks and is easy to remove.

Understanding the Trade-offs

No material is perfect. To make an informed decision, it is crucial to understand Teflon's limitations.

Relative Softness and Wear Resistance

While durable in many contexts, Teflon is a relatively soft material. In high-load, high-friction mechanical applications, it can be susceptible to creep and abrasion unless reinforced with other materials like glass or carbon.

Difficulty in Bonding

Its non-stick, low-friction surface makes it notoriously difficult to bond to other materials using conventional adhesives. Specialized surface treatments are often required, which can add complexity and cost to the manufacturing process.

Higher Cost

Compared to common plastics like polyethylene or polypropylene, Teflon is significantly more expensive. Its use is typically justified only when its unique high-performance properties are a strict requirement.

Making the Right Choice for Your Goal

Ultimately, selecting Teflon depends entirely on the specific demands of your project.

- If your primary focus is performance in extreme environments: Teflon is an elite choice for withstanding aggressive chemicals, high temperatures, and electrical stress.

- If your primary focus is reducing friction or creating a non-stick surface: Teflon's low coefficient of friction is one of the best available for industrial and commercial use.

- If your primary focus is structural strength or low cost: You should evaluate other polymers or composites, as Teflon's primary advantages are not mechanical strength or price.

Choosing the right material begins with a clear understanding of the core problem you need to solve.

Summary Table:

| Advantage | Key Benefit | Ideal For |

|---|---|---|

| Non-Stick & Low Friction | Prevents sticking, reduces wear | Cookware, bearings, seals |

| Chemical Inertness | Resists corrosive substances | Chemical processing, labware |

| Thermal Stability | Performs from -270°C to 260°C | Aerospace, high-temp applications |

| Electrical Insulation | Excellent dielectric strength | Wiring, electronics, cables |

Need high-performance PTFE components for your project?

At KINTEK, we specialize in manufacturing precision PTFE (Teflon) components—including seals, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors. Whether you require prototypes or high-volume orders, our custom fabrication expertise ensures you get parts that leverage Teflon's full advantages for your specific application.

Contact us today to discuss your requirements and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers