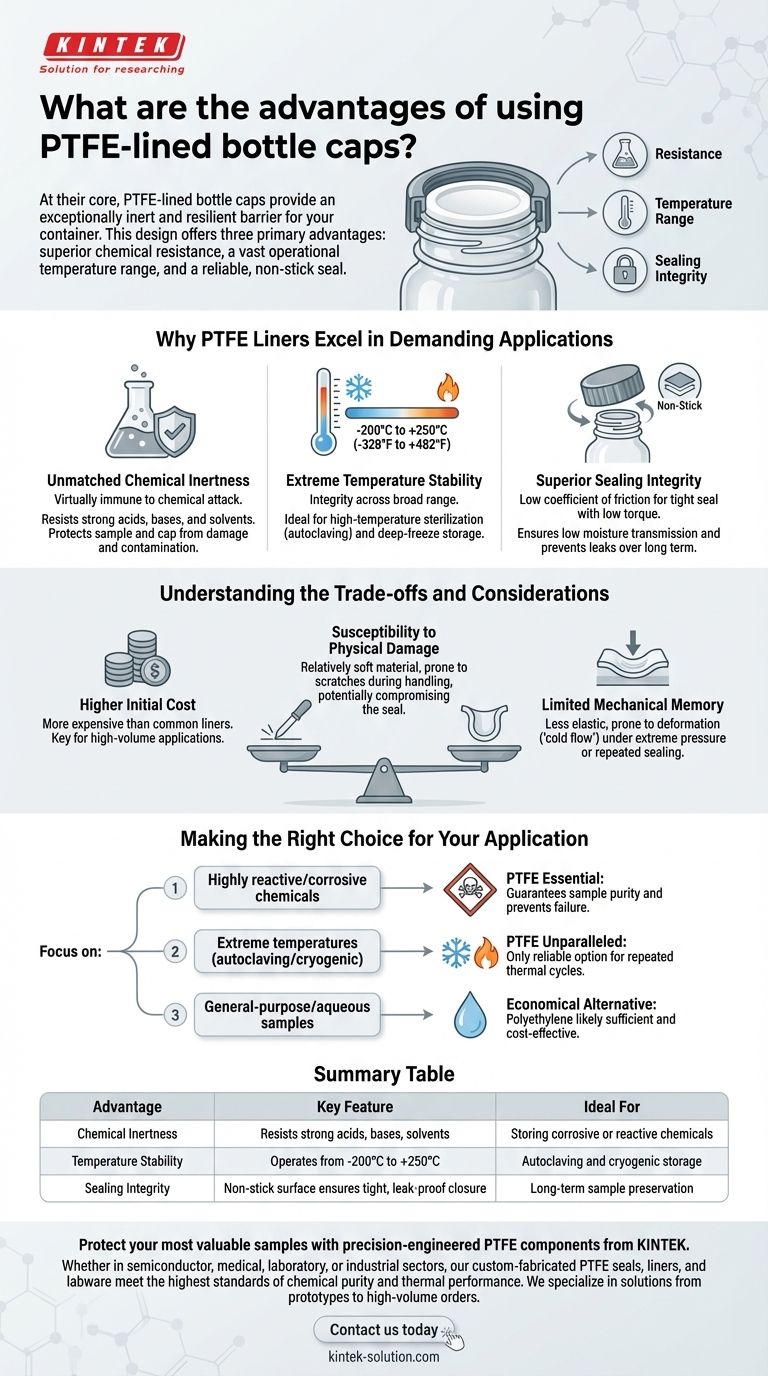

At their core, PTFE-lined bottle caps provide an exceptionally inert and resilient barrier for your container. This design offers three primary advantages: superior chemical resistance against nearly all solvents and acids, a vast operational temperature range suitable for autoclaving and cryogenic storage, and a reliable, non-stick seal that ensures the integrity of the contents.

The fundamental purpose of a PTFE liner is to isolate the contents of a container from the cap material. This creates a chemically non-reactive, temperature-stable, and contaminant-free sealing environment, protecting the purity and stability of valuable or aggressive substances.

Why PTFE Liners Excel in Demanding Applications

The unique properties of Polytetrafluoroethylene (PTFE), the material used in Teflon coatings, are what make these caps so effective. It acts as an elite shield, defending against conditions that would cause standard cap liners to fail.

Unmatched Chemical Inertness

A PTFE liner is virtually immune to chemical attack. It will not react with or degrade when exposed to strong acids, bases, solvents, and other corrosive chemicals.

This protects the sample from contamination that could be leached from a less-resistant liner. It also protects the cap itself from being damaged by the container's contents.

Extreme Temperature Stability

PTFE maintains its integrity across an exceptionally broad temperature range, typically from -200°C to +250°C (-328°F to +482°F).

This stability makes PTFE-lined caps ideal for applications involving high-temperature sterilization, such as autoclaving, as well as for the deep-freeze storage of biological samples.

Superior Sealing Integrity

The low coefficient of friction, or "non-stick" quality, of PTFE allows for a tight seal with relatively low torque. The cap closes smoothly and opens just as easily without binding or sticking.

This property, combined with the material's durability, ensures low moisture transmission and a secure closure that prevents leaks and sample evaporation over the long term.

Understanding the Trade-offs and Considerations

While PTFE liners offer premium performance, it's important to weigh their characteristics against your specific needs. Objectivity requires acknowledging potential downsides.

Higher Initial Cost

PTFE is a high-performance polymer, and its manufacturing process makes it more expensive than common liner materials like polyethylene or polypropylene. This higher upfront cost is a key consideration for general-purpose or high-volume applications where its advanced properties are not strictly necessary.

Susceptibility to Physical Damage

While chemically robust, PTFE is a relatively soft material. The liner can be scratched or gouged by sharp instruments during cleaning or handling. A compromised liner surface can trap contaminants or fail to create a perfect seal.

Limited Mechanical Memory

PTFE is not as elastic as some other sealing materials. In applications involving extreme pressure changes or repeated, high-torque sealing, the liner may be prone to deformation ("cold flow") over time, which could eventually impact sealing performance.

Making the Right Choice for Your Application

Selecting the correct cap liner is a critical decision based on the chemical being stored, the required temperature range, and your budget.

- If your primary focus is storing highly reactive or corrosive chemicals: PTFE is the essential choice to guarantee sample purity and prevent container failure.

- If your primary focus is applications involving extreme temperatures: PTFE's unparalleled thermal stability makes it the only reliable option for repeated autoclaving or cryogenic storage.

- If your primary focus is general-purpose storage of aqueous or non-aggressive samples: A more economical liner material, such as polyethylene, is likely sufficient and more cost-effective.

Choosing a cap with a PTFE liner is an investment in certainty, ensuring your valuable contents are protected under the most demanding conditions.

Summary Table:

| Advantage | Key Feature | Ideal For |

|---|---|---|

| Chemical Inertness | Resists strong acids, bases, and solvents | Storing corrosive or reactive chemicals |

| Temperature Stability | Operates from -200°C to +250°C | Autoclaving and cryogenic storage |

| Sealing Integrity | Non-stick surface ensures tight, leak-proof closure | Long-term sample preservation |

Protect your most valuable samples with precision-engineered PTFE components from KINTEK.

Whether you are in the semiconductor, medical, laboratory, or industrial sector, our custom-fabricated PTFE seals, liners, and labware are designed to meet the highest standards of chemical purity and thermal performance. We specialize in creating solutions from prototypes to high-volume orders, ensuring your materials are safeguarded under extreme conditions.

Contact us today to discuss your specific requirements and let our expertise enhance your application's reliability and safety.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Bottles for Diverse Industrial Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What are the base characteristics of PTFE? Unlocking Extreme Performance in Friction, Temperature, and Chemical Resistance

- What are some common applications of machined PTFE? Leverage its Unique Properties for Demanding Applications

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- What are the primary applications of PTFE fasteners and custom parts? Critical Solutions for Extreme Environments