At its core, the primary advantages of using PTFE (polytetrafluoroethylene) for rotary shaft lip seals are its exceptionally low friction, wide operating temperature range, superior chemical resistance, and ability to handle high pressures and velocities. These properties allow PTFE seals to succeed in demanding environments where traditional rubber or elastomer seals would quickly fail.

The decision to use a PTFE seal is a strategic one. It's not just a material swap; it's an upgrade for applications that push beyond the limits of conventional seals, ensuring reliability in the face of extreme temperatures, aggressive chemicals, or high-speed operations.

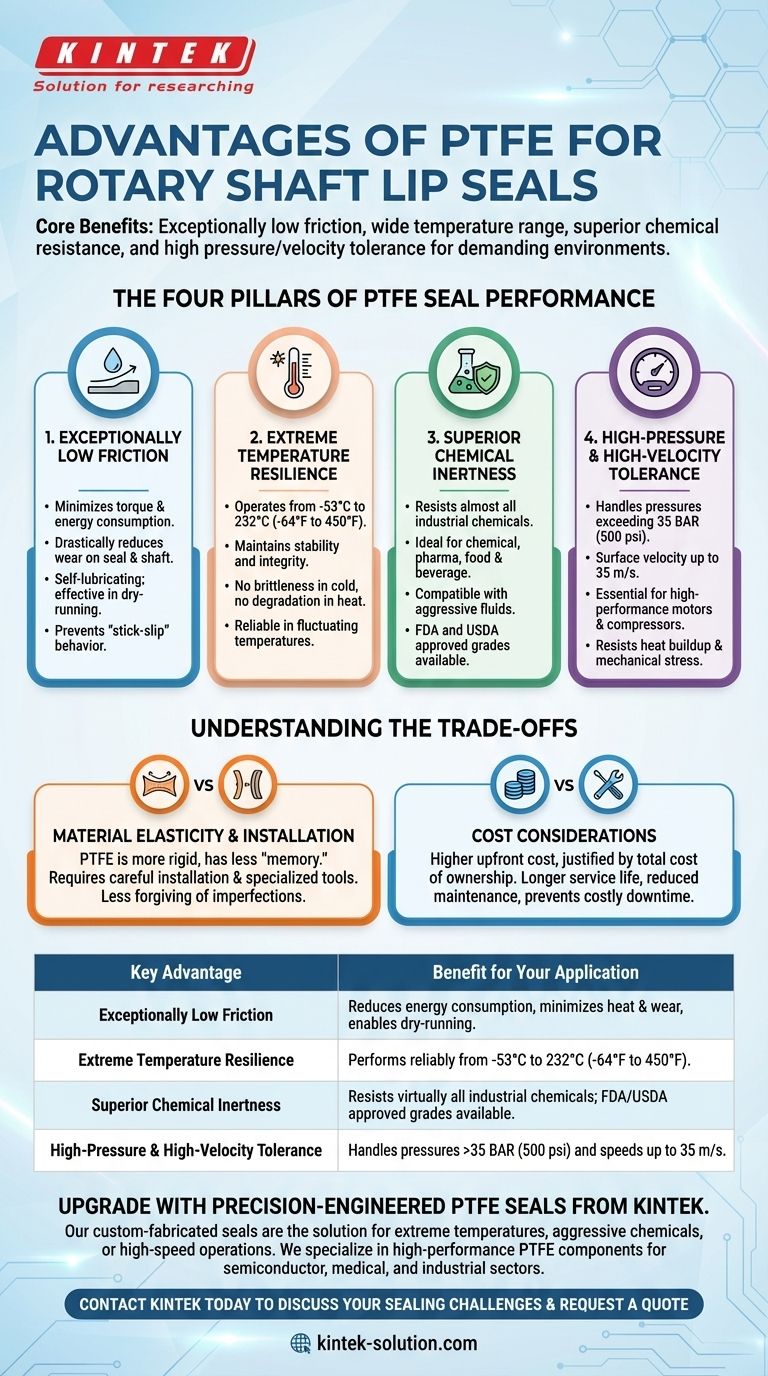

The Four Pillars of PTFE Seal Performance

PTFE rotary shaft seals consistently outperform their elastomer counterparts in four critical areas that define their suitability for high-performance and demanding industrial applications.

1. Exceptionally Low Friction

PTFE has one of the lowest coefficients of friction of any solid material, which translates into significant operational benefits. This inherent slipperiness minimizes the torque required to rotate the shaft, reducing energy consumption.

This low-friction nature also means the seal generates very little heat during operation. It glides smoothly over the shaft surface, drastically reducing wear on both the seal and the shaft itself.

Critically, PTFE is self-lubricating, which allows it to function effectively in dry-running conditions without external lubrication, preventing the common "stick-slip" behavior that can cause jerky movements and premature wear.

2. Extreme Temperature Resilience

PTFE seals maintain their integrity and performance across an exceptionally wide temperature range, typically from -53°C to 232°C (-64°F to 450°F).

Unlike rubber seals that can become brittle and crack in extreme cold or degrade and soften in high heat, PTFE remains stable. This ensures a reliable seal in equipment that experiences significant temperature fluctuations.

3. Superior Chemical Inertness

PTFE is chemically inert to almost all industrial chemicals and fluids. This makes it the ideal choice for sealing applications in the chemical processing, pharmaceutical, and food and beverage industries.

Its compatibility extends to aggressive fluids and most modern lubricants that would cause traditional elastomer seals to swell, shrink, or dissolve over time. Many grades are also FDA and USDA approved for sanitary applications.

4. High-Pressure and High-Velocity Tolerance

Engineered PTFE seals are designed for dynamic, high-stress environments. They can provide a tight, reliable seal at pressures exceeding 35 BAR (500 psi).

Furthermore, they can handle very high rotational speeds, with surface velocity capabilities of up to 35 m/s. This makes them essential for high-performance motors, compressors, and other rotating equipment where elastomer seals would be destroyed by heat buildup and mechanical stress.

Understanding the Trade-offs

While PTFE offers superior performance in demanding conditions, it's important to understand the trade-offs compared to traditional elastomer seals. Objectivity requires acknowledging these differences.

Material Elasticity and Installation

PTFE is a more rigid plastic compared to the flexible, rubber-like nature of elastomers. It has less "memory" and is not as forgiving of imperfections on the shaft surface or significant shaft runout (wobble).

Installation of a PTFE lip seal often requires more care and specialized tools to avoid damaging the seal lip. Its rigidity means it cannot be stretched into place as easily as a rubber seal.

Cost Considerations

PTFE seals typically have a higher upfront cost than standard nitrile or viton seals. The investment is justified by the total cost of ownership.

The longer service life, reduced maintenance requirements, and prevention of costly downtime in critical applications often make PTFE the more economical choice over the lifespan of the equipment.

Making the Right Choice for Your Application

Selecting the right seal material is a direct function of your application's specific demands. Your decision should be based on the operational environment and performance goals.

- If your primary focus is extreme operating conditions: Choose PTFE for its unmatched performance in high temperatures, aggressive chemical environments, and high-pressure/high-speed applications.

- If your primary focus is minimizing maintenance and maximizing equipment life: The durability and low-wear characteristics of PTFE reduce replacement frequency and protect shafts from damage, lowering long-term costs.

- If your primary focus is a standard, low-cost application: A traditional elastomer seal may be sufficient and more cost-effective for environments with moderate temperatures, standard lubricants, and lower speeds or pressures.

Ultimately, choosing a PTFE seal is an investment in the reliability and longevity of your critical equipment.

Summary Table:

| Key Advantage | Benefit for Your Application |

|---|---|

| Exceptionally Low Friction | Reduces energy consumption, minimizes heat & wear, enables dry-running. |

| Extreme Temperature Resilience | Performs reliably from -53°C to 232°C (-64°F to 450°F). |

| Superior Chemical Inertness | Resists virtually all industrial chemicals; FDA/USDA approved grades available. |

| High-Pressure & High-Velocity Tolerance | Handles pressures >35 BAR (500 psi) and speeds up to 35 m/s. |

Upgrade your equipment's reliability with precision-engineered PTFE seals from KINTEK.

If your application involves extreme temperatures, aggressive chemicals, or high-speed operations, our custom-fabricated PTFE seals are the solution. We specialize in manufacturing high-performance PTFE components for the semiconductor, medical, laboratory, and industrial sectors, from prototypes to high-volume orders.

Let our expertise in precision production ensure your critical equipment operates flawlessly. Contact KINTEK today to discuss your specific sealing challenges and request a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the key benefits of PTFE in custom fabrication? Unlock Performance in Extreme Conditions

- Why is PTFE suitable for cryogenic or high-temperature applications? Unmatched Thermal Stability from -450°F to 500°F

- What are the primary applications of PTFE fasteners and custom parts? Critical Solutions for Extreme Environments

- What are some common applications of machined PTFE? Leverage its Unique Properties for Demanding Applications

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications