In industrial applications, the primary advantages of Teflon are its exceptional chemical inertness, high-temperature stability, and extremely low coefficient of friction. These core properties make it an invaluable material for creating durable components like seals, bushings, and gaskets that perform reliably in harsh operating conditions where other materials would quickly fail.

Teflon's true value isn't just one single benefit, but its unique combination of properties. It solves critical engineering challenges by reducing friction, resisting chemical attack, and withstanding extreme heat, which translates directly to lower maintenance, longer equipment life, and improved operational efficiency.

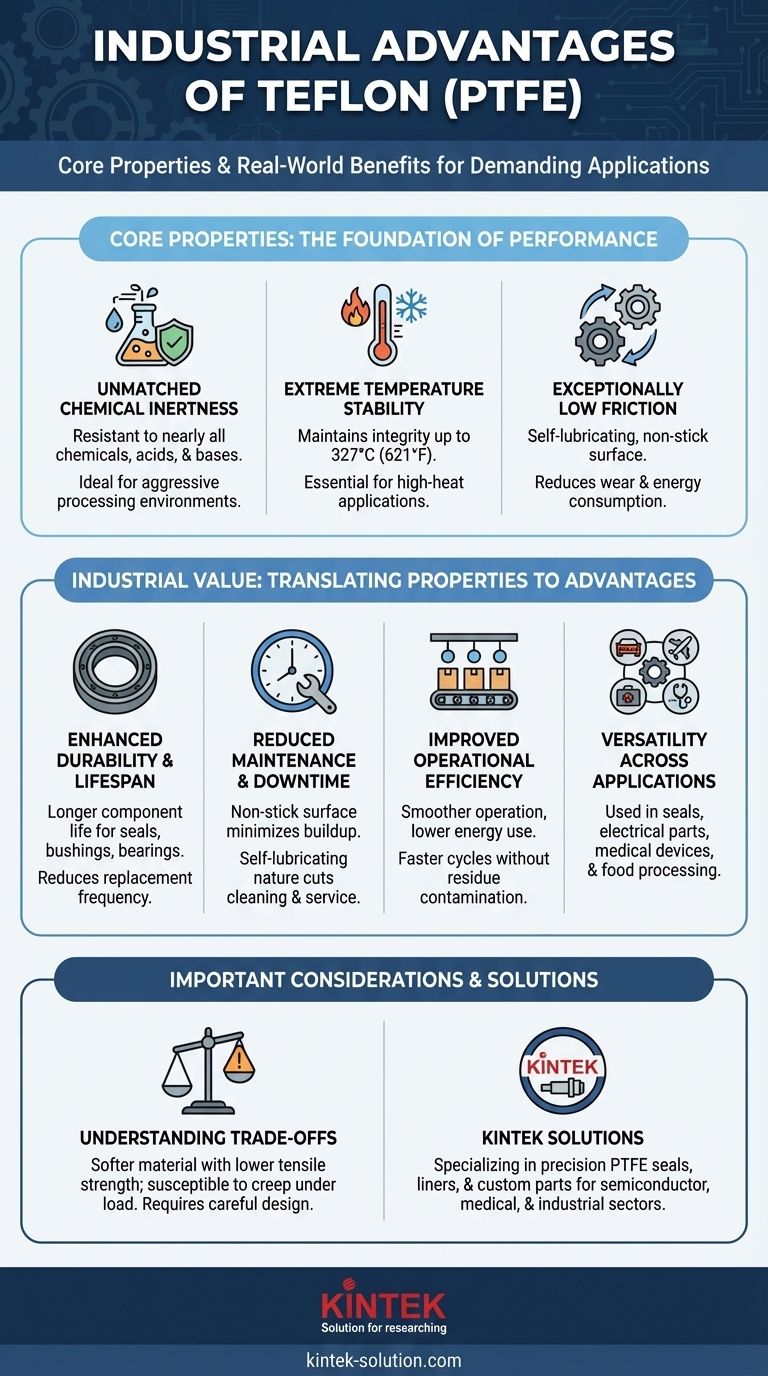

The Core Properties of Teflon

To understand Teflon's industrial impact, we must first examine its fundamental characteristics. These unique material traits are the source of its wide-ranging benefits.

Unmatched Chemical Inertness

Teflon (PTFE) is resistant to nearly all industrial chemicals, acids, and bases. This makes it the ideal choice for seals, gaskets, and linings in chemical processing environments where component degradation is a major concern.

Extreme Temperature Stability

This material maintains its integrity and performance across a wide temperature range, capable of withstanding continuous service temperatures up to 327°C (621°F). This stability is critical for components in high-heat machinery and aerospace applications.

Exceptionally Low Friction

Teflon has one of the lowest coefficients of friction of any solid material, giving it superior non-stick and self-lubricating qualities. This property is essential for reducing wear and energy consumption in moving parts like bearings and bushings.

Superior Electrical Insulation

As an excellent electrical insulator, Teflon is used for wiring and components in demanding electronic applications. Its high dielectric strength prevents electrical arcing even at high voltages and frequencies.

How These Properties Translate to Industrial Value

The theoretical properties of Teflon create tangible, real-world advantages that improve performance and reduce costs across industries.

Enhanced Durability and Lifespan

Teflon's resistance to wear, chemicals, and heat means components made from it last significantly longer. Bushings and bearings experience less degradation, extending the life of critical machinery and reducing the frequency of replacement.

Reduced Maintenance and Downtime

The non-stick surface prevents the buildup of viscous or sticky materials, which is crucial in food processing and manufacturing. This self-cleaning aspect, combined with its self-lubricating nature, drastically cuts down on cleaning schedules and maintenance needs.

Improved Operational Efficiency

By minimizing friction between moving parts, Teflon allows machinery to run more smoothly and with less energy. In applications like conveyor belts or food processing equipment, its non-stick quality ensures faster production cycles without residue buildup or contamination.

Versatility Across Applications

This unique balance of properties allows Teflon to be used in countless applications. It is found in seals for the automotive industry, electrical components in aerospace, and even medical devices where chemical inertness is paramount.

Understanding the Trade-offs

While its benefits are significant, Teflon is not a universal solution. Acknowledging its limitations is key to using it effectively.

Mechanical Strength Considerations

Compared to metals, Teflon is a softer material with lower tensile strength. In high-load applications, it may require reinforcement or be used as a coating on a stronger substrate rather than as a standalone structural component.

Susceptibility to Creep

Under sustained mechanical stress, especially at elevated temperatures, Teflon can be susceptible to "creep," a slow, permanent deformation. Design engineers must account for this behavior in applications involving constant, heavy loads.

Cost vs. Performance

Teflon is a premium, high-performance polymer. Its cost is higher than many commodity plastics, meaning its use must be justified by the specific demands of the application, such as extreme temperatures or chemical exposure that other materials cannot handle.

Making the Right Choice for Your Application

Selecting Teflon should be a deliberate decision based on your primary operational goal.

- If your primary focus is maximizing equipment lifespan in harsh environments: Teflon's unparalleled chemical and heat resistance makes it the definitive choice for seals, gaskets, and liners.

- If your primary focus is reducing operational friction and maintenance: The self-lubricating and non-stick properties of Teflon bushings, bearings, and surface coatings will directly lower energy consumption and downtime.

- If your primary focus is ensuring product purity and preventing contamination: Teflon's inertness and non-stick surface are critical for applications in the food processing, medical, and pharmaceutical industries.

Ultimately, leveraging Teflon correctly allows engineers to solve problems that are simply beyond the capabilities of conventional materials.

Summary Table:

| Key Advantage | Industrial Benefit |

|---|---|

| Chemical Inertness | Resists nearly all industrial chemicals, acids, and bases. |

| High-Temperature Stability | Withstands continuous service up to 327°C (621°F). |

| Low Coefficient of Friction | Provides self-lubricating, non-stick properties to reduce wear. |

| Excellent Electrical Insulation | Prevents electrical arcing in demanding electronic applications. |

Ready to solve your toughest engineering challenges with high-performance PTFE components?

At KINTEK, we specialize in manufacturing precision PTFE components—including seals, liners, labware, and custom parts—for the semiconductor, medical, laboratory, and industrial sectors. Whether you need a prototype or a high-volume order, our expertise ensures you get durable, efficient components that extend equipment life and reduce maintenance.

Contact us today to discuss your specific application and get a custom solution!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support