In static applications, the primary advantage of a square ring over an O-ring is its ability to create a more robust, stable seal under high pressure. The square ring's flat, rectangular cross-section provides a significantly larger sealing surface compared to the O-ring's single line of contact, making it more resistant to failure.

While the O-ring is a versatile and effective all-around seal, the square ring is a specialized component whose geometry is engineered for superior performance and stability in high-pressure static sealing environments.

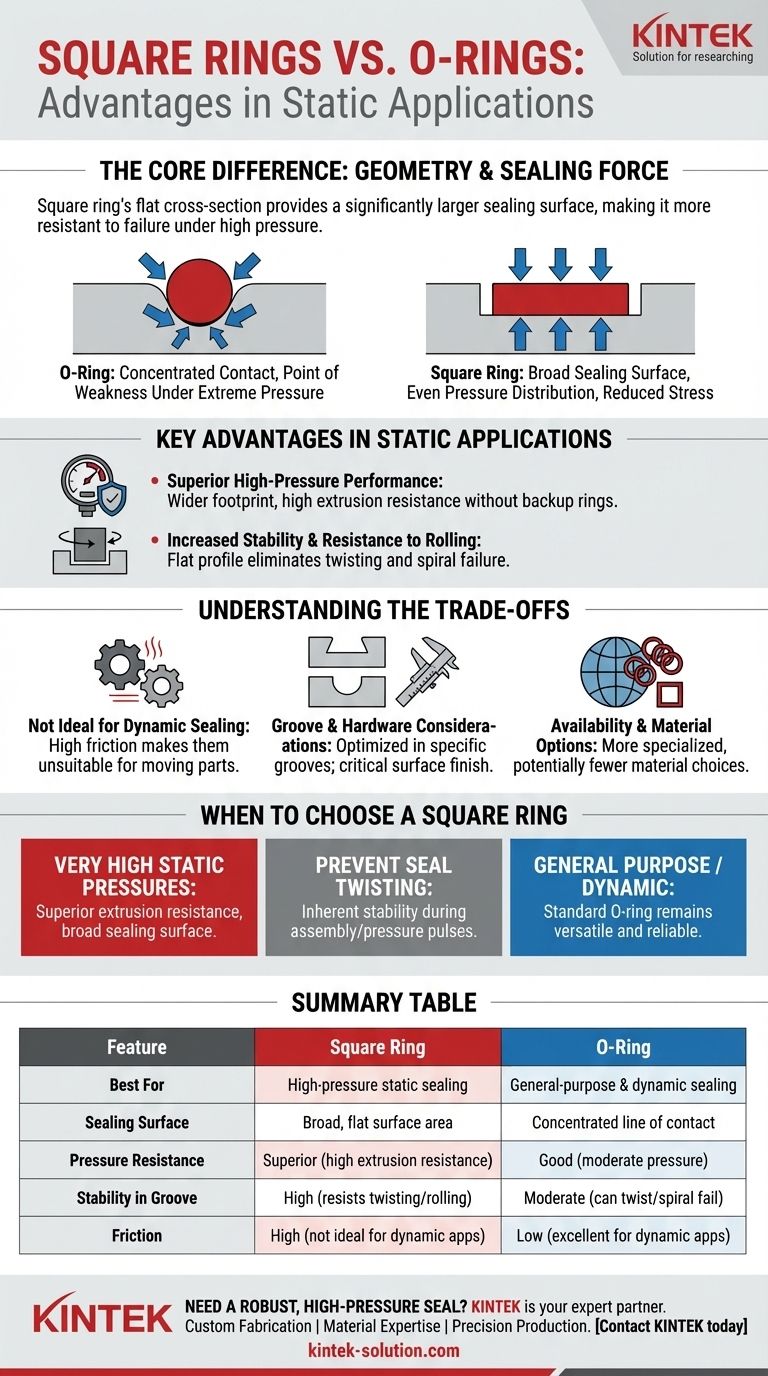

The Core Difference: Geometry and Sealing Force

The functional advantages of a square ring stem directly from the fundamental difference in its shape compared to a traditional O-ring.

The O-Ring's Concentrated Contact

An O-ring's round cross-section is designed to be squeezed within a groove, creating a predictable and concentrated line of sealing force against the mating surfaces.

This design is effective for a wide range of applications but can become a point of weakness under extreme pressure.

The Square Ring's Broad Sealing Surface

A square ring, by contrast, has a flat top and bottom. This geometry creates a much broader initial sealing surface.

When system pressure is applied, it acts across this entire flat face, distributing the sealing force more evenly and over a larger area.

How Pressure Amplifies the Seal

This broad surface area is the key to the square ring's high-pressure capability. The force is less concentrated, reducing stress on the material.

This makes the square ring inherently more resistant to being pushed, or extruded, into the small clearance gap between the sealed components—a common failure mode for O-rings under high pressure.

Key Advantages in Static Applications

The square ring's geometry translates into specific, measurable performance benefits when movement is not a factor.

Superior High-Pressure Performance

The wider sealing footprint and resulting resistance to extrusion allow square rings to handle significantly higher static pressures than a comparable O-ring without requiring backup rings.

Increased Stability and Resistance to Rolling

The flat profile of a square ring makes it exceptionally stable within its groove. It cannot twist or roll during assembly or under pressure cycles.

This eliminates the risk of spiral failure, a condition where an O-ring twists in its groove, compromising the seal.

Understanding the Trade-offs

Choosing a square ring is a specific engineering decision, not a universal upgrade. Its strengths in static sealing are often disadvantages elsewhere.

Not Ideal for Dynamic Sealing

The large, flat surface that creates a strong static seal also generates significantly more friction. This makes square rings generally unsuitable for dynamic applications like reciprocating pistons or rotating shafts, where an O-ring is the superior choice.

Groove and Hardware Considerations

While square rings can often be retrofitted into standard O-ring grooves (also known as dovetail grooves), their performance is optimized in a groove designed specifically for their rectangular shape. The surface finish of the hardware is also critical for ensuring a reliable seal.

Availability and Material Options

O-rings are a ubiquitous commodity. They are available in a vast array of materials, sizes, and durometers (hardnesses) from countless suppliers. Square rings are more specialized, which can sometimes limit material choices and availability.

When to Choose a Square Ring

Your decision should be driven entirely by the specific demands of your application.

- If your primary focus is sealing very high static pressures: The square ring is the superior choice for its exceptional extrusion resistance and broad sealing surface.

- If your primary focus is preventing seal twisting during assembly or pressure pulses: The square ring's inherent stability offers a definitive advantage over an O-ring.

- If you need a cost-effective, general-purpose static seal for moderate pressures or a dynamic seal: The standard O-ring remains the industry's most versatile and reliable solution.

Ultimately, selecting the correct seal requires matching the component's design strengths to the precise pressures and conditions it will face.

Summary Table:

| Feature | Square Ring | O-Ring |

|---|---|---|

| Best For | High-pressure static sealing | General-purpose & dynamic sealing |

| Sealing Surface | Broad, flat surface area | Concentrated line of contact |

| Pressure Resistance | Superior (high extrusion resistance) | Good (moderate pressure) |

| Stability in Groove | High (resists twisting/rolling) | Moderate (can twist/spiral fail) |

| Friction | High (not ideal for dynamic apps) | Low (excellent for dynamic apps) |

Need a Robust, High-Pressure Seal for Your Critical Application?

If your project demands the superior stability and extrusion resistance of a square ring, KINTEK is your expert partner. We specialize in the precision manufacturing of high-performance PTFE components, including custom square rings and seals, for the most demanding environments in the semiconductor, medical, laboratory, and industrial sectors.

We deliver the critical advantages you need:

- Custom Fabrication: From prototype to high-volume production, we engineer seals to your exact specifications.

- Material Expertise: Advanced PTFE and other polymers for superior chemical resistance and performance.

- Precision Production: Ensuring every seal meets the exact tolerances required for reliable, high-pressure static sealing.

Let us help you solve your toughest sealing challenges. Contact KINTEK today for a consultation!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability